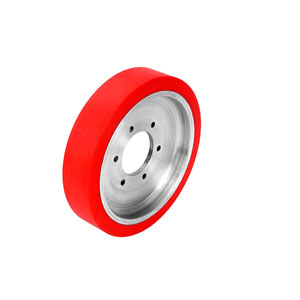

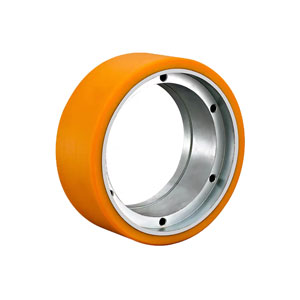

Polyurethane Forklift Tires

Polyurethane Forklift Tires and Wheels are made from a durable polyurethane material known for its resilience and wear resistance. These tires and wheels enhance forklift and material handling equipment performance. They provide long-lasting durability in diverse environments like warehouses, factories, and distribution centers.

Polyurethane Tires Wheels for Electric Forklifts

Key Features Polyurethane Forklift Tires

- Excellent wear and tear resistance

- Low rolling resistance

- Non-marking tread

- High rebound and shock absorption

- Minimal maintenance and long service life

Applications of Polyurethane Forklift Tires

- AGVs & Electric Forklifts

- Warehousing & Distribution Centers

- Manufacturing Plants & Assembly Lines

- Cold Storage & Food Facilities

- Logistics & Cross-Docking Hubs

- Automotive & Electronics Plants

- Pharmaceutical & Medical Equipment Handling

- Retail & Airport Logistics

Polyurethane Tyred Wheels for Material Handling or Warehouse Equipment

- Product Specifications

- Gallery

Based on its way of connection, polyurethane buffer could be divided into three series: stud type, platen type, and flange-plate type. For each series, there are 14 to 21 specifications, and each specification corresponds to the buffer of each capacity.

Below are the size requirements you need to provide if you need custom polyurethane forklift tires and wheels.

1.Material- High-performance cast or injection-molded polyurethane

- Shore A or D hardness: 85A – 75D (customizable)

- Optional additives: anti-static, oil-resistant, non-marking, cut-resistant

- Cast iron (for heavy-duty)

- Aluminum (for lightweight)

- Steel (for high-strength bonding)

- Custom core design available

- Press-On Tires- Pre-formed PU tires pressed onto metal hubs; quick to replace.

- Mold-On Tires- PU is directly molded onto the core for superior bonding and durability.

- Tyred Wheels (PU Tread on Cast Core)-Replaceable polyurethane tread on reusable metal core.

- Outer Diameter (OD): 100 mm – 600 mm

- Width: 50 mm – 200 mm

- Bore/Hub types: Keyed, Splined, Tapered, Ball Bearing, or custom

- Varies by size and design: 300 kg – 5,000 kg+

- High static and dynamic load support

- Temperature range: -30°C to +80°C

- Suitable for dry, clean, oil-exposed, or chemically exposed environments

Related Products

Custom Solution for your equipment

Looking for forklift tires that last longer, carry more, and protect your floors? Our polyurethane forklift tires are engineered for high load capacity, non-marking operation, and extended wear life—making them ideal for indoor warehousing, logistics, and heavy-duty industrial environments. We offer custom-molded solutions to meet your exact application needs.

Polyurethane tires offer higher load capacity, better wear resistance, and are non-marking—ideal for indoor, smooth-surface use. They also reduce rolling resistance and require less maintenance over time.

Yes, especially when paired with cast iron or steel cores. We can customize them to handle high loads, frequent use, and demanding environments like factories or logistics centers.

- It depends on your application and equipment.

- 1.Press-on tires are quick to replace.

- 2.Mold-on tires offer stronger bonding for heavy-duty use.

- 3.Tyred wheels allow the tread to be replaced without changing the core.

Absolutely. We specialize in bonding PU tread to metal cores, offering excellent structural support and shock absorption for high-load forklifts.

Service life depends on usage and environment, but polyurethane tires typically last 2–4 times longer than rubber tires under the same conditions.