Polyurethane V Belts

Polyurethane V belts are durable and flexible power transmission belts made from thermoplastic polyurethane (TPU). Their V-shaped cross-section fits into matching V-groove pulleys. These urethane drive belts transfer power and motion between rotating shafts in machinery. They provide superior flexibility, strength, and resistance to abrasion and chemicals, ensuring long-lasting performance.

Polyurethane V Belts Manufacturer and Suppliers in China

Why use PU V Belts?

- Last longer than traditional rubber belts in high-friction applications,

- Weldable and customizable,

- Withstand oils, greases, and solvents,

- Reduce downtime and maintenance costs,

- Offer precision fit ensure reliable power transmission with reduced slippage.

Applications of Polyurethane PU V Belts

- Conveyor systems

- Packaging equipment

- CNC and woodworking machines

- Textile and printing machinery

- Automated machinery

- Light to medium-duty power transmission

Custom PU V-Belts | PU Transmission Belts | PU Flat Drive Belts

- Product Specifications

- Gallery

- Material: Thermoplastic Polyurethane (TPU)

- Reinforcement Optional: Polyester or Kevlar/Aramid cord (for reinforced types), Steel wire ( for special load conditions).

- Hardness (Shore A): 80A – 95A (commonly 85A or 90A),Custom hardness available on request

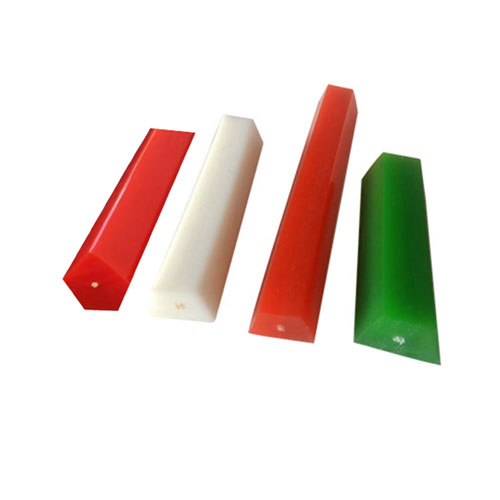

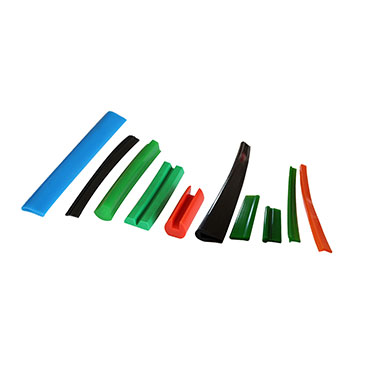

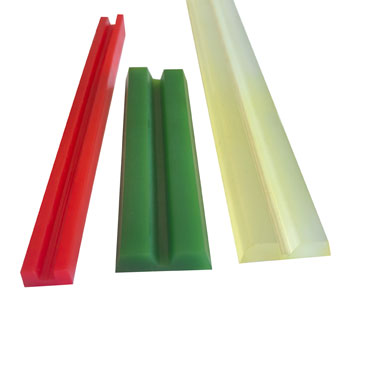

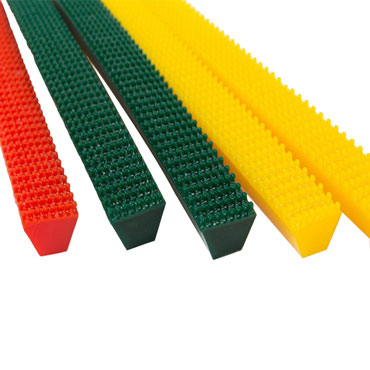

- Color: Red, Orange, Green, Blue,Black and so on.

- Operating range of Temperature Resistance: –20°C to +80°C

- Tensile Strength of Solid PU: ~30–50 MPa

- Tensile Strength of Reinforced belts: Up to 100 MPa (with cords)

- Weldability: Yes,Quick on-site joining reduces downtime, Useing Heat butt welding and friction welded,or overlap welding.

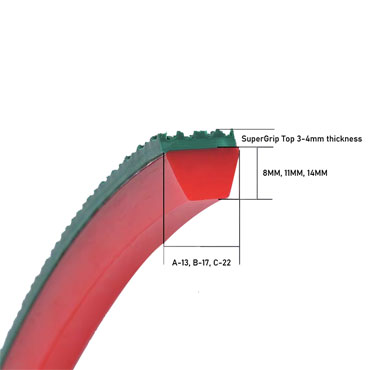

PU V-Belts and Super Grip V-belts Specification

| Cross Section | Dimensions | + Super Grip Top PU or PVC | Length | Minimum Pulley Ø | Pretension | Weight per meter |

| Type | W * H (mm) | Total Height(mm) | Mtrs/Roll | (mm) | Max.6% | (kg) |

| Y/6 | 6*4 | 200 | 40 | 3% | 0.045 | |

| M/8 | 8*5 | 200 | 55 | 3% | 0.046 | |

| Z/10 | 10*6 | 9.5 | 100 | 65 | 3% | 0.070 |

| A/13 | 13*8 | 12 | 30 | 80-100 | 3% | 0.12 |

| B/17 | 17*11 | 14 | 30 | 115-150 | 3% | 0.197 |

| C/22 | 22*14 | 17 | 30 | 145-210 | 3% | 0.297 |

| D/32 | 32*19 | 50 | 215 | 3% | 0.567 |

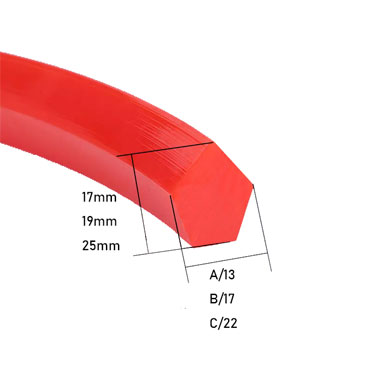

PU Ridge-Top V-Belts Specification

| Cross Section | Dimensions | Length | Minimum Pulley Ø | Pretension | Weight per meter |

| Pentagonal Type | W * H (mm) | Mtrs/Roll | (mm) | Max.5% | (kg) |

| A/13 | 13*17 | 30 | 140 | 3% | 0.15 |

| B/17 | 17*19 | 30 | 200 | 3% | 0.22 |

| C/22 | 22*25 | 30 | 240 | 3% | 0.384 |

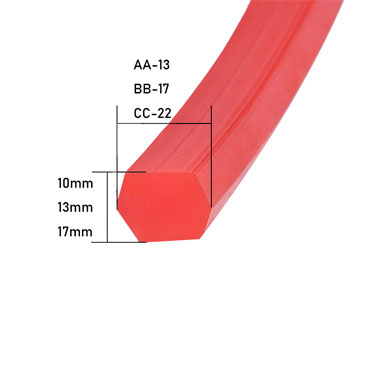

PU Hexagonal V-Belts

| Cross Section | Dimensions | Length | Minimum Pulley Ø | Pretension | Weight per meter |

| Doouble V-Type | W * H (mm) | Mtrs/Roll | (mm) | Max.5% | (kg) |

| AA | 12.5*10 | 30 | 105 | 3% | 0.15 |

| BB | 17*13 | 30 | 143 | 3% | 0.22 |

| CC | 22*17 | 30 | 216 | 3% | 0.384 |

PU Twin V Belts Specification

| Cross Section | Dimensions | Length | Minimum Pulley Ø | Pretension |

| Type | W * H (mm) | Mtrs/Roll | (mm) | Max.6% |

| M20*8 | 20*8 | 100 | 45 | 3% |

| M21*7.5 | 21*7.5 | 50 | 50 | 3% |

| Z29*7.5 | 29*7.5 | 50 | 75 | 3% |

| A29*8 | 29*8 | 50 | 80 | 3% |

| A29*10 | 29*10 | 50 | 85 | 3% |

| A30*9.5 | 30*9.5 | 50 | 85 | 3% |

Feature of Polyurethane V-belts

- High tensile strength and flexibility

- Excellent resistance to abrasion, oil, and chemicals

- Quiet, smooth, and vibration-resistant operation

- Easy to weld, join, and customize on-site

- Available in various colors, hardness and profiles

- Suitable for V-groove pulleys, conveyors, and high-speed drives

Related Products

Polyurethane Plastic Weldable Vee belting for Transmission

As a trusted manufacturer and supplier of polyurethane V belts, we specialize in high performance solutions for power transmission and conveying systems.

We provide a wide range of standard PU vee belts and custom V-belt profiles, including reinforced, weldable, and grip-top options, tailored to meet the needs of OEMs and system integrators worldwide.

Polyurethane V-belts provide longer service life, greater chemical and oil resistance, and better wear resistance compared to traditional rubber belts. They also offer more precise tracking and less maintenance due to their low stretch and high tensile strength.

Yes, we offer custom extrusions ,Injection and cast polyurethane solutions. Polyurethane V-belts can be tailored to specific sizes, profiles, and reinforcement options (such as Kevlar or polyester cord). Custom designs allow us to meet unique application requirements, including specific environmental or mechanical needs.

Choosing the right polyurethane V belt depends on factors such as pulley size, load requirements, environmental conditions, and temperature tolerance. We recommend consulting with our technical team to help you select the correct belt for your system’s specifications.

The lifespan of a polyurethane V-belt can vary depending on load, operating conditions, and maintenance. However, polyurethane belts generally last longer than rubber belts, offering greater durability in abrasive or oil-heavy environments and high-speed machinery.

The price of polyurethane V-belts varies based on factors such as size, profile, reinforcement, and custom features. While they may be priced higher than rubber belts, their longer lifespan and reduced maintenance costs offer significant long-term value. Contact us for a custom quote based on your requirements.