AGV Wheels

AGV wheels power Automated Guided Vehicles (AGVs)—autonomous mobile robots used in warehouses, factories, and distribution centers. We make them from high-performance polyurethane to ensure excellent wear resistance and quiet operation. These wheels roll smoothly, protect floors with their non-marking tread, and provide precise movement. Their durability and performance help AGVs run reliably in demanding industrial environments.

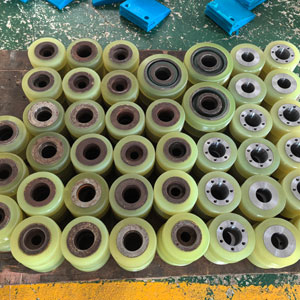

Polyurethane AGV Drive & Traction Wheels

Key Features of Polyurethane AGV Wheels

- High wear resistance,

- Shock absorption and quiet rolling, non-marking operation on indoor floors,

- Excellent grip and torque transmission

- Suitable for tight indoor spaces and long distances

Why Choose Our AGV Wheels?

- Long service life with minimal maintenance,

- Engineered for smart automation environments,

- Custom-fit for any AGV brand or system,

- Customizable for load, diameter, durometer, and hub design.

Polyurethane AGV Load, Guide & Support Wheels

- Product Specifications

- Gallery

| Specification | Details |

| Tread Material | High-performance cast polyurethane (custom Shore A/D hardness available) |

| Core Material | Aluminum, steel, cast iron, or plastic (based on load and application) |

| Wheel Diameter | 50 mm – 300 mm (custom sizes available) |

| Tread Width | 20 mm – 100 mm (depending on design) |

| Load Capacity | Up to 2,000 kg per wheel (varies by size and core material) |

| Hardness Range | Shore A 75–98 or Shore D 55–70 (application-specific) |

| Bearing Type | Precision ball bearing, roller bearing, or plain bore (customizable) |

| Temperature Resistance | –30°C to +80°C (up to +120°C with high-temp compounds) |

| Mounting Options | Keyed bore, hub with keyway, press-fit, or bushing |

| Color Options | Standard orange, red, black, or custom-matched |

| Applications | AGV drive wheels, load wheels, idler wheels, caster wheels, guide wheels |

What Makes AGV Wheels Different?

- Material: Most AGV wheels are made with polyurethane tread, chosen for its durability, quiet operation, and non-marking properties.

- Precision: AGV systems require high-precision wheels to ensure accurate navigation and minimal deviation.

- Functionality: Wheels are often divided into types—drive wheels (powered), load wheels (support weight), and guide or support wheels (stabilize direction).

Related Products

Custom Polyurethane Solutions

Can’t find the wheel you need? We specialize in custom polyurethane molding and can manufacture AGV wheels to your exact design or performance requirements.

Options Available:

- Custom diameters and widths

- Core materials (aluminum, cast iron, plastic)

- Hardness options (Shore A/D)

- Keyways, bushings, or bearing integration

Need Help Choosing the Right AGV Wheels?Contact our team to get expert recommendations or request a custom quote.

AGV wheels are designed for automated guided vehicles in logistics and industrial environments. Polyurethane provides high wear resistance, low noise, excellent grip, and floor protection—making it superior to rubber or plastic for long-term AGV use.

Service life depends on load, speed, and usage conditions. However, our high-quality polyurethane wheels typically last 3–5 times longer than traditional rubber wheels in AGV systems.

Yes, we specialize in custom polyurethane molding. We can produce AGV wheels tailored to your required dimensions, hub design, load capacity, hardness, and core material.

Drive wheels transmit power and move the AGV, while load wheels support weight. Drive wheels usually have a keyed hub or bore, while load and guide wheels are designed to bear static or dynamic loads.

Our AGV wheels are used in warehousing, automotive, electronics, e-commerce, and pharmaceutical logistics, where automation, precision, and floor protection are critical.