Cable Protection System Offshore Wind

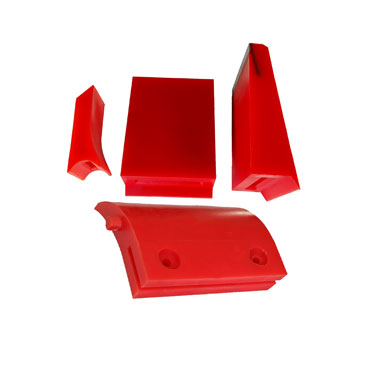

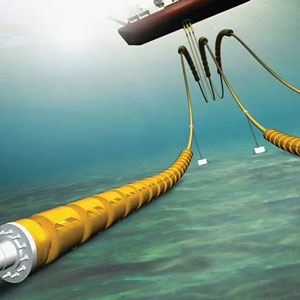

Protect your offshore wind farm investments with our cable protection systems for offshore wind. Our polyurethane-molded solutions guard subsea power cables against abrasion, bending, and harsh marine conditions, ensuring long-term reliability and lower maintenance costs.

At LISEN, we design and manufacture custom urethane products and accessories for offshore and subsea cable protection. Our systems feature bend restrictors, bend stiffeners, J-tube seals, and polyurethane cable protection tubes. They secure shore ends, pipeline crossings, and undersea cable routes. These durable components simplify installation and deliver reliable performance in demanding offshore wind projects.

Types of Cable Protection Products and Accessories

Why Choose Our Cable Protection System Offshore Wind?

- Custom-engineered polyurethane designs for exact project specifications.

- Proven durability against extreme subsea abrasion and impact.

- Flexible solutions including bend restrictors, stiffeners, and sealing systems.

- Extended cable lifespan, lowering O&M costs in offshore wind farms.

Applications of Offshore Cable Protection Systems

- Offshore wind farm export and inter-array cables,

- Oil & gas subsea umbilicals and risers,

- Submarine power and telecom cables,

- Cable crossings over pipelines or seabeds,

- Shore-end cable landing and post-installation protection,

- Dynamic cable applications in floating wind farms.

Offshore and Subsea Cable Protection Systems

- Product Specifications

- Gallery

| Specification | Details | |

| Material | High-strength polyurethane elastomers for superior abrasion, impact, and corrosion resistance | |

| Components | Bend restrictors, bend stiffeners, J-tube seals, and protection tubes for complete subsea cable safeguarding | |

| Design | Modular and customizable for inter-array/export cables, shore-end installations, and dynamic offshore conditions | |

| Depth Rating | Suitable for shallow to deepwater subsea installations | |

| Installation | Two-piece or articulated designs for easy assembly and maintenance in offshore wind projects | |

| Compliance | Meets offshore wind and subsea industry standards for cable protection and operational safety | |

| Benefits | Extends cable service life, minimizes maintenance, ensures reliable performance in harsh marine environments |

Specification of Polyurethane Bending Restrictor

| Product | Cable | Length | Material | Hardness |

| Bend restrictor 3*70 | 3*70cable | 5M/8M | High-performance polyurethane PU | Shore 83D |

| Bend restrictor 3*80 | 3*80cable | 5M/8M | High-performance polyurethane PU | Shore 83D |

| Bend restrictor 3*120 | 3*120cable | 5M/8M | High-performance polyurethane PU | Shore 83D |

| Bend restrictor 3*185 | 3*185cable | 5M/8M | High-performance polyurethane PU | Shore 83D |

| Bend restrictor 3*200 | 3*200cable | 5M/8M | High-performance polyurethane PU | Shore 83D |

| Bend restrictor 3*240 | 3*240cable | 5M/8M | High-performance polyurethane PU | Shore 83D |

| Bend restrictor 3*300 | 3*300cable | 5M/8M | High-performance polyurethane PU | Shore 83D |

| Bend restrictor 3*400 | 3*400cable | 5M/8M | High-performance polyurethane PU | Shore 83D |

| Bend restrictor 3*500 | 3*500cable | 5M/8M | High-performance polyurethane PU | Shore 83D |

Specfication of Polyurethane Submarine Cable Protection Tube

| Dimensions of polyurethane protection pipes | Dimensions of Band | |||

| I.D | O.D | Thickness | Effective length | |

| 25mm | 65mm | 20mm | 1000-2000mm | L390*W19*T0.6 |

| 35mm | 75mm | L420*W19*T0.6 | ||

| 85mm | 125mm | L580*W19*T0.6 | ||

| 100mm | 140mm | L620*W19*T0.6 | ||

| 105mm | 145mm | L640*W19*T0.6 | ||

| 130mm | 170mm | L720*W19*T0.6 | ||

| 140mm | 180mm | L750*W19*T0.6 | ||

| 150mm | 190mm | L780*W19*T0.6 | ||

| 160mm | 200mm | L810*W19*T0.6 | ||

| 25mm | 75mm | 25mm | L420*W19*T0.6 | |

| 35mm | 85mm | L450*W19*T0.6 | ||

| 85mm | 135mm | L610*W19*T0.6 | ||

| 100mm | 150mm | L660*W19*T0.6 | ||

| 105mm | 155mm | L670*W19*T0.6 | ||

| 130mm | 180mm | L750*W19*T0.6 | ||

| 140mm | 190mm | L780*W19*T0.6 | ||

| 150mm | 200mm | L810*W19*T0.6 | ||

| 160mm | 210mm | L850*W19*T0.6 | ||

| 25mm | 85mm | 30mm | L450*W19*T0.6 | |

| 35mm | 95mm | L390*W19*T0.6 | ||

| 85mm | 145mm | L500*W19*T0.6 | ||

| 100mm | 160mm | L690*W19*T0.6 | ||

| 105mm | 165mm | L710*W19*T0.6 | ||

| 130mm | 190mm | L780*W19*T0.6 | ||

| 140mm | 200mm | L810*W19*T0.6 | ||

| 150mm | 210mm | L850*W19*T0.6 | ||

| 160mm | 220mm | L880*W19*T0.6 | ||

Date Sheet of MDI- combined polyether polyol elastomer physical property

| MDI- Combined Polyether Polyol | ||||

| Prepolymers | - | - | 3H830D | 3H830D |

| Chain extender | - | - | ELAST*879 | ELAST®875 |

| Hardness 23°C | DIN 53505 | Shore | 83D | 87D |

| Hardness -5℃ | DIN 53505 | Shore | 850 | 890 |

| Hardness 80℃ | DIN 53505 | Shore | 75D | 830 |

| Weight ratio of prepolymer components | - | - | 100 | 100 |

| Weight ratio of chain extender | - | - | 97 | 65 |

| Tensile modulus | ISO 527 50mm/min | MPa | 1800-2000 | 2700-2900 |

| Tensile strength | ISO 527 50mm/min | MPa | 51 | 79 |

| Elongation at break | ISO 527 50mm/min | %6 | 20-30 | 8-10 |

| Unnotched impact toughness 20℃ | ASTM.D256 | KJ/㎡ | 8.2 | 11.9 |

| Unnotched impact toughness 0℃ | ASTM.D256 | KJ/㎡ | 7.3 | 9.5 |

| Relative density | g/mm | 1.17 | 1.19 | |

| Casting and curing | ||||

| Mold temperature | ℃ | 100-120* | ||

| Gel time(100g mix 23℃) | min | 25 | 10 | |

| Gel time (100g mix ke hot mold) | - | 2'05” | 2'35” | |

| Demolding time | min | 30 | 30 | |

| Post-curing | h/℃ | 14/100 | 14/100 | |

Date Sheet of Polyurethane Elastomer Physical Property

| Polyurethane Prepolymer Properties | |

| % NCO | 4.3±0.2 |

| Appearance@20℃ | Transparent liquid |

| Viscosity@80℃/mPa·s | 800 |

| Melting condition,h/°C,20L | 8/80 |

| Curing agent | MOCA |

| Chain expansion coefficient(NH2/NCO) | 0.9 |

| Amount of curing agent(per 100 parts of prepolymer) | 12.5 |

| Temperature of prepolymer/°C | 80 |

| Curing agent temperature/°C | 110 |

| Recommended mold temperature/°C | 100 |

| Gel time/min(400g mix) | 6~8 |

| Demolding time/min(400g mix) | 30~40 |

| Post-curing,h@℃ | 16/100 |

| Hardness@20℃,Shore A | 85±2 |

| Hardness@20℃,Shore D | - |

| Tensile strength/MPa | 28.6 |

| 100% constant tensile strength/MPa | 7.6 |

| 300% constant tensile strength/MPa | 11.2 |

| Elongation at break/% | 520 |

| Tear Strength/(Right Angle,KN/m) | 80 |

| Resilience/% | 32 |

| DIN roller abrasion/m㎡ | 162 |

Related Products

Get Your Offshore Wind Cable Protection System Today

Protect your offshore wind cables with custom polyurethane cable protection systems from LISEN. Designed for subsea and offshore applications, our CPS solutions safeguard cables from bending, abrasion, and harsh marine conditions, ensuring long-term reliability.

With advanced engineering and modular components like bend restrictors, stiffeners, and protection tubes, our systems reduce downtime, extend cable service life, and maintain uninterrupted power transmission for wind farms and subsea infrastructure.

Don’t risk costly cable failures — contact LISEN today to discuss your project requirements and receive a tailored offshore wind cable protection solution designed for maximum safety, efficiency, and performance.

A Cable Protection System (CPS) for offshore wind is designed to safeguard subsea cables from environmental stresses such as abrasion, bending, and fatigue. These systems are crucial for ensuring the longevity and reliability of power transmission in offshore wind farms.

Polyurethane Bend Restrictors are used to prevent over-bending of flexible flowlines, umbilicals, and cables during installation and service. They lock when the minimum bend radius is reached, protecting the cable from damage.

Bend Stiffeners are conical devices made from polyurethane that gradually stiffen the cable as it enters a J-tube. They limit the movement of the cable, preventing over-bending and ensuring the structural integrity of the cable during installation and operation.

J-Tube Seals are used to protect cables where they enter or exit a J-tube. They prevent water ingress and protect the cable from mechanical damage, ensuring the longevity and reliability of subsea cables.

Yes, Cable Protection Systems can be tailored to meet the specific requirements of each project. Customization ensures optimal protection and performance, accommodating factors such as cable type, installation method, and environmental conditions.