Centrifugal/Spin Casting Polyurethane Molding

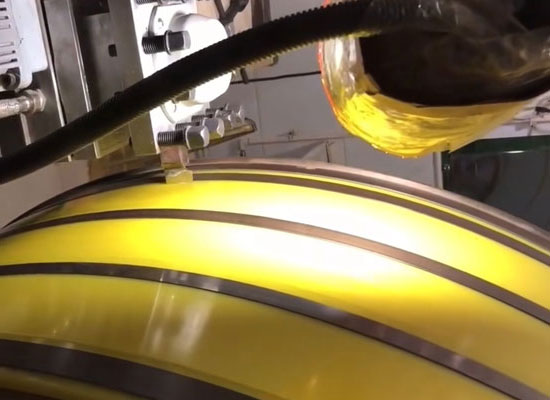

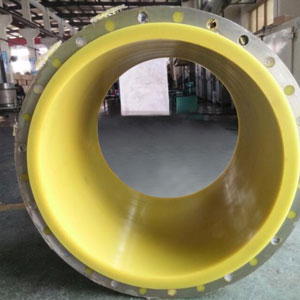

Centrifugal casting, also called spin casting polyurethane, is a molding process that uses centrifugal force to spread liquid polyurethane inside a rotating mold. Unlike rotational casting, which relies on slow multi-axis rotation and gravity, this method spins rapidly on a single axis. The process creates dense, bubble-free parts with consistent wall thickness.

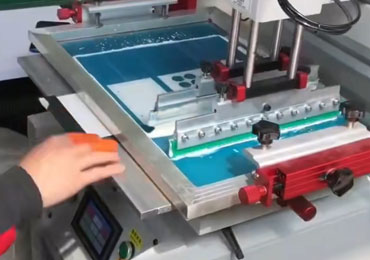

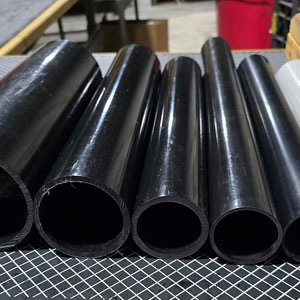

Manufacturers use it to make polyurethane sheets, screen printing squeegees, scrapers, and thin-wall cylinders that demand accuracy and strength.

Why Choose Spin Casting Polyurethane Capabilities

- Decades of experience producing precision-molded polyurethane components.

- End-to-end customization from design through production.

- Strict quality control to ensure consistency and performance.

- Flexibility in production volumes – from prototypes to medium batch runs.

- Commitment to durability, reliability, and High solvent resistance squeegee or blade or sheets.

Centrifugal Casting Polyurethane Production Process

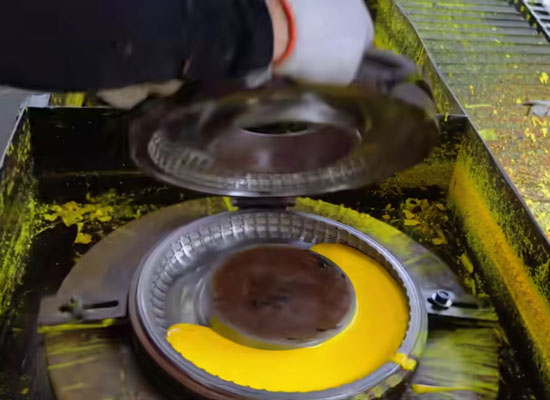

- Mold Preparation: A circular or cylindrical mold is preheated and coated with a release agent.The mold is mounted on a centrifuge that rotates at high speed around a single axis.

- Material Mixing & Degassing: Liquid polyurethane components (prepolymer + curative) are precisely measured and mixed.Degassing removes trapped air to prevent voids.

- Material Pouring:The mixed polyurethane is poured into the rotating mold.Centrifugal force drives the material outward, creating an even layer along the mold wall.

- Centrifugal Molding & Distribution: High-speed rotation ensures uniform thickness and eliminates bubbles.Material compacts against the mold wall for dense, consistent properties.

- Curing: The part cures under controlled temperature and rotation until it solidifies.This step determines the final hardness and physical properties.

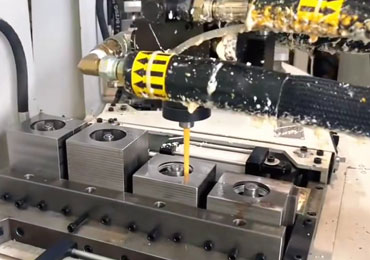

- Demolding & Finishing: Once cured, the polyurethane part is removed.Secondary processes such as trimming, machining, or surface finishing may be applied.

Advantages of Centrifugal Casting Polyurethane

- Produces void-free, dense parts with consistent quality.

- Ensures uniform wall thickness, smooth surfaces, and high dimensional accuracy.

- Minimizes air bubbles and voids through centrifugal force.

- Delivers excellent mechanical properties with consistent density and durability.

- Flexible for medium-volume production, offering cost-effective solutions.

- Supports customization of hardness, color, and chemical resistance.

- Suitable for a wide range of products including tubes, sheets, squeegees, scrapers, and bushings.

Case of Centrifugal/Spin-Cast Polyurethane

Applications of Centrifugal/Spin-Cast Polyurethane

Why Choose Us?

As a trusted custom polyurethane manufacturer, we provide:

- Expertise in centrifugal (spin) casting polyurethane for hollow, cylindrical, and thin-walled components.

- End-to-end solutions from design and prototyping to small and medium production runs.

- High-quality, smooth, and void-free components tailored to your specifications.

- Reliable delivery, flexibility, and consistent performance for specialized parts.

Contact us today to discuss your spin casting polyurethane project and discover how our custom solutions can enhance your equipment and applications.

It is a process where liquid polyurethane is poured into a mold that rotates at high speed around a single axis, using centrifugal force to create dense, uniform parts.

This process is ideal for products with uniform wall thickness such as polyurethane sheets, tubes, scrapers, and screen printing squeegees.

Centrifugal casting uses centrifugal force on a single axis to distribute material evenly, while rotational casting uses multi-axis rotation at low speeds to cure liquid urethane.

It delivers smoother surfaces, fewer defects, and greater consistency in thickness, especially for long, continuous parts.

No. Rollers with metal cores are typically produced using rotational casting or open casting, not centrifugal casting.

Industries like printing, material handling, mining, and construction rely on centrifugal-cast products for durability and wear resistance.