Compression Molding Polyurethane

Compression molding polyurethane is a manufacturing process where pre-measured polyurethane material is placed into a heated mold cavity, then compressed under controlled pressure and temperature. The polyurethane flows, cures, and solidifies to form durable, precise, and high-performance components. Key benefits include:

- High dimensional accuracy and consistent quality

- Ability to produce complex geometries and custom profiles

- Excellent wear, impact, and chemical resistance

- Cost-effective production for medium- to high-volume runs.

Compared with other polyurethane processes, compression molding typically requires longer production times, as the material must fully react and cure. It also generates more non-recyclable waste, which may slightly increase the per-part cost. Despite this, it remains highly effective for producing durable, custom parts in small to medium quantities.

Our Compression Molding Capabilities

- Custom Urethane Components – Bushings, gaskets, rollers, pads, and bumpers;

- Medium & High-Volume Production – Scalable solutions for production runs;

- Complex Geometries – Internal grooves, undercuts, and multi-feature parts;

- Custom Formulations – Hardness, flexibility, abrasion, chemical resistance, or flame-retardant grades;

- Precision Tooling – Heated molds for consistent curing and high-quality surfaces.

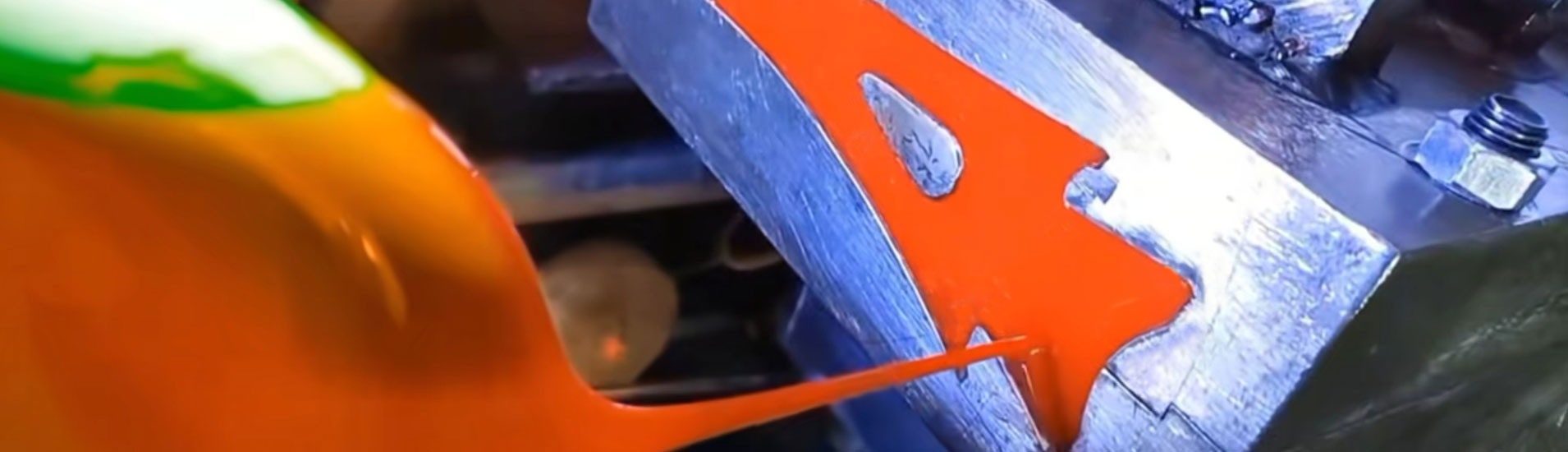

Our Compression Molding Polyurethane Process

- Design & Material Selection: Collaborate with our engineers to choose the best polyurethane formulation based on your application requirements.

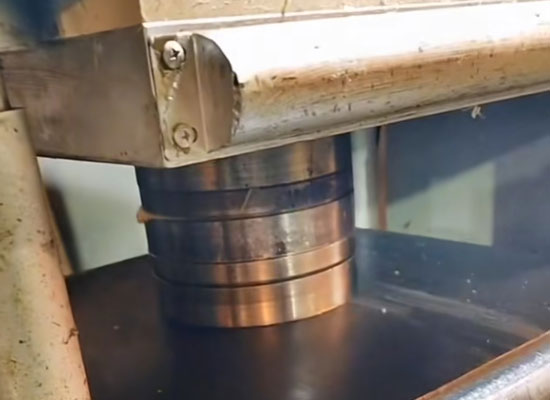

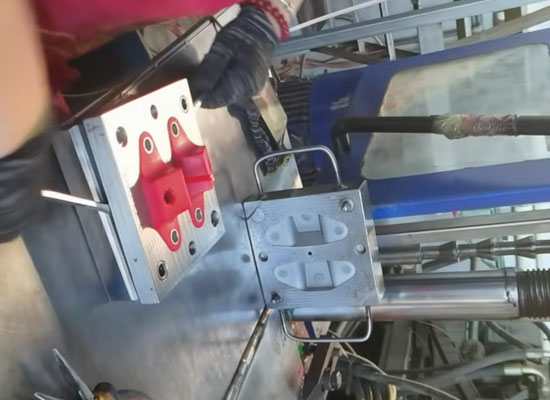

- Precision Mold Preparation: Our molds are carefully designed to achieve exact dimensions, smooth finishes, and repeatable results.

- Compression Molding: Polyurethane is placed in the mold and subjected to high pressure, forming strong, uniform components.

- Finishing & Quality Control: Each part undergoes trimming, inspection, and rigorous testing to ensure it meets your specifications.

Quality Control of Compression-Molded Polyurethane Components

- Dimensional inspections to maintain tight tolerances.

- Material testing for hardness, abrasion resistance, and chemical durability.

- Surface quality checks for smooth, defect-free finishes.

- Process monitoring to control temperature, pressure, and curing time consistency.

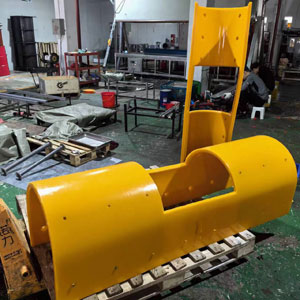

Case of Compression Molded Polyurethane

Applications of Compression Molding Polyurethane

Why Choose Us?

As a trusted custom polyurethane manufacturer, we provide:

- Expertise in compression molding polyurethane for diverse applications.

- End-to-end solutions from design and prototyping to full-scale production.

- High-quality, durable, and precise components tailored to your needs.

- Reliable delivery, competitive pricing, and consistent quality.

Contact us today to discuss your compression molding polyurethane project and discover how our custom solutions can enhance your products and operations.

Compression molding polyurethane is a process where pre-measured polyurethane material is placed in a heated mold, compressed, and cured to form durable, precise components.

- High dimensional accuracy and tight tolerances;

- Excellent wear, impact, and chemical resistance;

- Ability to produce complex geometries and custom profiles;

- Cost-effective for medium- to high-volume production;

Common industries include automotive, industrial machinery, material handling, mining, construction, aerospace, and consumer products.

We produce bushings, mounts, seals, rollers, pads, bumpers, gaskets, liners, and custom shapes tailored to your application.

Yes. We can adjust hardness, flexibility, abrasion resistance, chemical resistance, color, and flame-retardant properties to meet your specifications.

Provide drawings, CAD files, or sample parts, and our team will provide a custom quote tailored to your production requirements.