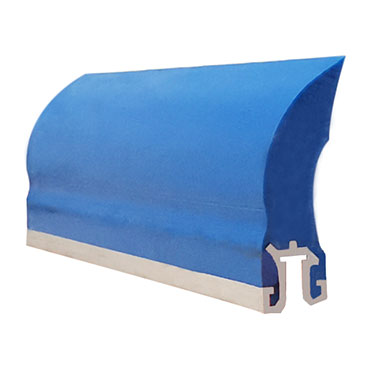

Conveyor Belt Scraper Blades

High-performance conveyor belt scraper blades aggressively remove carryback to reduce spillage, protect belts, and improve operational efficiency. Durable polyurethane and urethane blades deliver long service life in mining, quarrying, cement, and bulk-handling conveyors.

Industrial Conveyor Belt Scraper Blades for Aggressive Material Removal

Why Choose Our Scraper Blades

- Durable Materials: Polyurethane and urethane options resist abrasion and outlast conventional rubber blades.

- Aggressive Cleaning: Industrial scraper blades efficiently remove heavy carryback and protect equipment.

- Custom Designs: Options include primary, secondary, and fully customized scraper systems for OEM and industrial conveyors.

- Reduced Downtime: Reliable performance under high-load conditions reduces maintenance frequency and extends conveyor life.

Applications & Industries

- Mining & Quarrying: Efficiently remove bulk materials like coal, ore, and aggregates.

- Cement & Building Materials: Protect belts and reduce spillage in high-load operations.

- Bulk Material Handling Systems: Ensure smooth, efficient operation with reliable scraper blades.

- Heavy Industrial Conveyors: Designed for industrial applications requiring long-lasting, high-performance scraper blades.

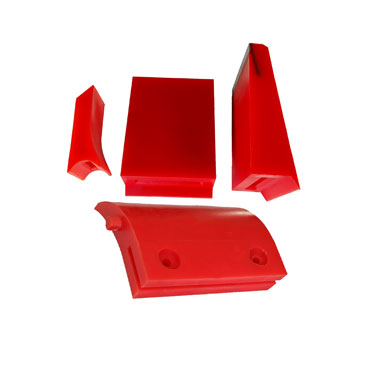

Customizable Polyurethane Conveyor Belt Scraper Blades

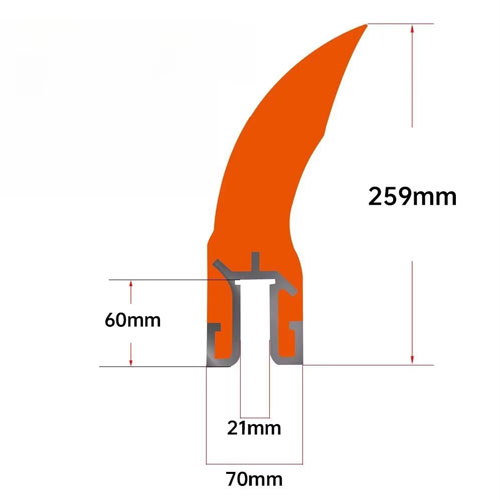

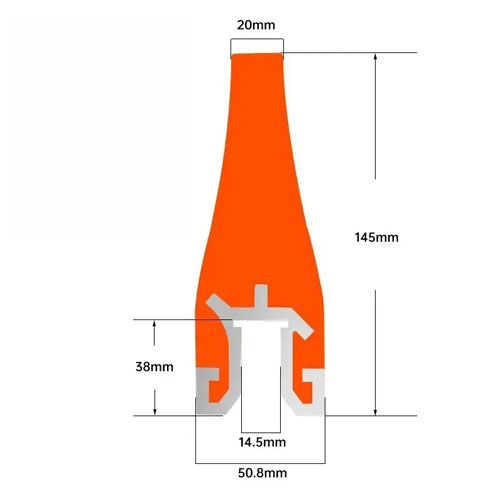

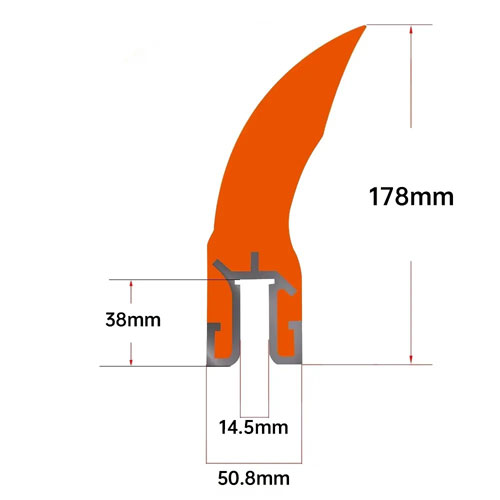

- Product Specifications

- Gallery

Technical Specifications - Conveyor Belt Scraper Blades

| Specification | Details / Options | Notes |

| Material | Polyurethane, Urethane, Optional Rubber | High abrasion resistance, long service life |

| Blade Type | Primary, Secondary, Heavy-Duty, Industrial, Mining, Aggregate | Select based on conveyor load and material type |

| Length | 300–2000 mm (custom lengths available) | Can be customized to match conveyor width |

| Thickness | 8–25 mm | Depending on material and wear requirements |

| Mounting Style | Bolt-on, Clamp-on | Fits most existing conveyor cleaning systems |

| Operating Temperature | -30°C to 80°C (Polyurethane), -20°C to 70°C (Urethane) | Suitable for most industrial environments |

| Hardness (Shore A) | 85–95 | Provides optimal balance of flexibility and abrasion resistance |

| Color | Yellow, Red, Blue, or Custom | Optional for material type identification |

| Applications | Mining, Quarrying, Cement, Aggregate, Bulk Material Handling | Aggressive carryback removal and reduced spillage |

| Replacement Compatibility | Works with most standard industrial conveyor scraper mounts | Easy installation and maintenance |

- Custom lengths, thickness, and hardness options are available to match your conveyor system.

- Durable polyurethane and urethane materials extend blade life and reduce maintenance frequency.

- Suitable for high-load, heavy-duty applications as well as industrial conveyors handling bulk materials.

Related Products

Replacement & Maintenance Solutions

- Belt Cleaner Replacement Blades: Fast, direct-fit replacement for worn scraper systems, restoring cleaning efficiency.

- Replacement Conveyor Belt Cleaner Blade: Cost-effective solution for worn primary or secondary scrapers.

- Heavy-Duty Scraper Options: Durable polyurethane blades reduce downtime and extend equipment service life.

- Note: For light-to-medium duty cleaning, consider our Conveyor Belt Wiper Blades series.

Polyurethane scraper blades provide a balance of wear resistance, flexibility, and belt protection. They outlast rubber and reduce belt wear compared to metal while delivering aggressive material removal.

Yes, our blades retrofit most standard belt cleaner and scraper frames, offering direct replacements without modification.

Use scraper blades for heavy-duty bulk or sticky materials (mining, aggregates, bulk handling). Use wiper/cleaner blades for light-to-medium duty cleaning or routine maintenance on logistics, packaging, or food-industry belts.

They effectively remove carryback, prevent material buildup, minimize belt wear, reduce cleanup labor, and require fewer replacements due to durable polyurethane construction.

Regularly inspect the blade and frame for wear or damage, clean debris, and check alignment and contact pressure. Replace worn or uneven blades promptly to avoid reduced cleaning efficiency or belt damage.