Conveyor Belt Skirting

Conveyor belt skirt installs along the belt edges to prevent spillage, reduce dust, and control material flow. It improves safety, protects equipment, and increases operational efficiency by sealing gaps between the belt and conveyor structure.

Our belt skirting solutions create tight seals that stop material loss, improve conveyor efficiency, and extend equipment life.

Rubber Conveyor Belt Skirting | Durable and Cost-Effective Solutions

Functions of Conveyor Belt Skirting

- Prevent Material Spillage: Skirting helps seal the gap between the conveyor belt and the conveyor structure, which reduces the risk of material falling off the belt during operation. This is especially important in industries where bulk materials, like grains, coal, or minerals, are being transported.

- Containment of Dust and Debris: By sealing off areas where materials might escape, skirting helps in controlling dust and debris. This is crucial in maintaining a cleaner working environment, especially in industries like mining or cement manufacturing.

- Improve Safety: Conveyor belt skirting ensures that material does not spill onto the floor, reducing the likelihood of slips, trips, and falls in the workplace. It also helps reduce the risk of fire hazards by containing potentially hazardous materials.

- Protect Conveyor Systems: Skirting also prevents materials from getting caught in the machinery or damaging the equipment, thus improving the overall efficiency and lifespan of the conveyor system.

Applications of Conveyor Belt Skirting

- Mining: Protects against the spillage of materials like coal, minerals, and ores.

- Bulk Material Handling: Helps contain materials like sand, gravel, and cement.

- Recycling: Prevents contamination and material loss when handling recyclable materials.

- Food Processing: Ensures food safety by preventing contamination from spilled or exposed materials.

Durable Rubber Skirting Solutions for Conveyor Systems

- Product Specifications

- Gallery

| Specification | Details |

| Material Options | Rubber (Natural, Synthetic), Polyurethane (PU), |

| Thickness | Typically 6mm to 25mm (customizable) |

| Width | Varies from 100mm to 500mm (customizable) |

| Length | Customizable to fit specific conveyor systems and applications |

| Hardness | Rubber: 60-70 Shore A, Polyurethane: 85-95 Shore A |

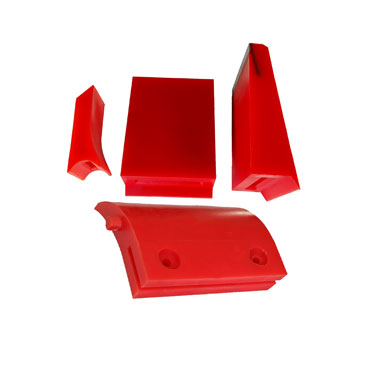

| Color Options | Black (standard), Blue, Green, Red (for certain materials) |

| Temperature Resistance | Rubber: -30°C to 70°C, Polyurethane: -40°C to 90°C |

| Abrasion Resistance | High abrasion resistance (especially for Polyurethane skirting) |

| Chemical Resistance | Rubber: Moderate to good (depends on type), Polyurethane: Excellent |

| UV Resistance | Moderate to high (Polyurethane generally offers better UV resistance) |

| Elasticity | Rubber: Good, Polyurethane: Excellent for impact resistance |

| Sealing Performance | Prevents material spillage and dust; reduces contamination and wear |

| Compression Set Resistance | High for Polyurethane, moderate for Rubber |

| Flexibility | High flexibility for rubber; Polyurethane more rigid but stronger in extreme conditions |

| Custom Options | Custom lengths, widths, and profiles available to match specific needs |

| Certifications | CE, ISO 9001 (if applicable) |

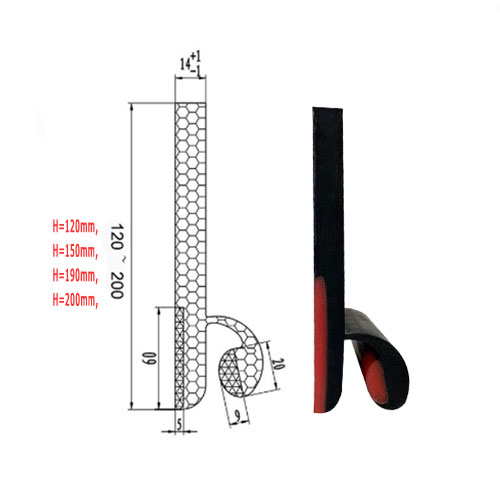

Technical Data of Double Seal Skirting Rubber

| Rubber Skirt Board made of composite polyurethane and rubber | |

| A. Skirt Rubber: | |

| Polymer | NR/Synthetic |

| Specific Gravity | 1.26g/cm3 |

| Tensile Strength | 10 MPa |

| Hardness | 60 +/- 5 Shore A |

| Elongattion | 450% |

| Wear Loss @10N | 260mm3 |

| Temperature | - 20 ~80 ℃ |

| B. Polyurethane skirt board: | |

| Specific Gravity | 1.25 |

| Wear Loss @10N | 60 mm3 |

| Hardness | 88 ± 3 Shore A |

| Coefficient of Friction | (To rubber) < 2.2 |

Key Features of Double Sealing Rubber Skirting Board

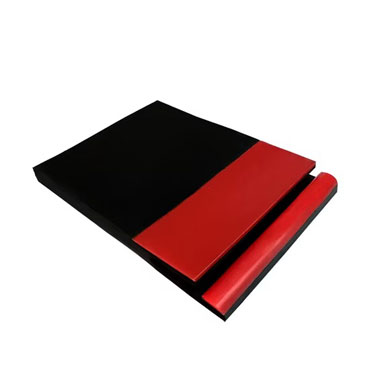

- Double layer structure, inside layer keeps materials, outside layer prevents dust-leakage.

- The parts where contact the belt is made of polyurethane, which have longer lifetime and do not damage the belt.

- Aluminum Clamp units are easy to install, adjust and maintain.

Related Products

Why Choose Our Conveyor Belt Skirting Solutions?

Our skirting products are engineered to meet the highest industry standards, ensuring your conveyor systems operate with maximum efficiency and minimal downtime. Here’s how our products benefit your operation:

- Prevent Material Loss & Contamination:Reduce spillage and avoid contamination by sealing the gap between the conveyor belt and the skirting. Perfect for industries handling powders, grains, chemicals, and bulk materials.

- Increase Conveyor Efficiency & Safety:Our skirting helps maintain optimal belt tracking and reduce the risk of wear and tear, ensuring smooth operation even under heavy load conditions.

- Customizable & Versatile:Whether you're looking for rubber skirting panels, double-sealed polyurethane skirting, or full skirting systems, our products can be tailored to meet your specific needs. Custom lengths and profiles are available for all applications.

- Durability in Extreme Conditions:Especially with polyurethane skirting, our solutions offer superior resistance to abrasion, temperature extremes, and harsh chemicals, ensuring long-lasting performance in even the most demanding environments.

- Protect your equipment and maximize the efficiency of your conveyor systems with our high-quality skirting solutions. Request a Quote or Contact Us to discuss custom requirements for your industry.

Common materials for Conveyor Belt Skirting include rubber (for standard applications) and polyurethane (for high-performance, heavy-duty applications). Polyurethane offers superior abrasion resistance, while rubber is more cost-effective for general use.

Choose rubber conveyor skirting for general industrial applications, where cost-efficiency and flexibility are key. Opt for polyurethane skirting when durability, high abrasion resistance, and performance in extreme conditions (e.g., mining or heavy materials) are required.

Yes, Conveyor Belt Skirting made from heat-resistant rubber or polyurethane can handle a range of temperatures. Polyurethane skirting generally offers better heat resistance and is ideal for high-temperature environments, such as in metal production or cement manufacturing.

Conveyor Belt Skirting is typically easy to install, using bolts, screws, or clamps to secure it along the conveyor system. Custom lengths and profiles can be tailored to fit your specific conveyor system. It’s recommended to follow manufacturer instructions or consult an expert for installation in challenging environments.

Regular inspections and maintenance are essential to ensure your Conveyor Belt Skirting remains effective. Check for wear and tear, especially at the contact points, and replace sections as needed to maintain a secure seal and prevent material loss.