Conveyor Belt Wiper Blades

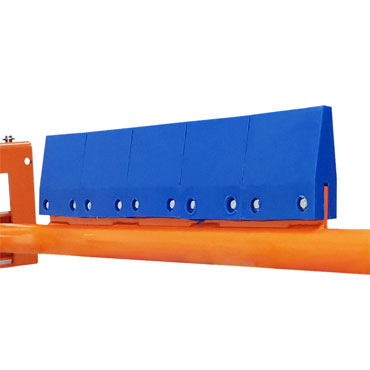

Conveyor belt wiper blades—also called belt wipers, polyurethane wiper blades, or urethane wiper blades—efficiently remove fines, dust, and carryback. They extend belt life, reduce buildup, prevent belt wear, and improve conveyor efficiency in primary and secondary.

Conveyor Belt Wiper Blades for Reliable, Long-Lasting Belt Cleaning Performance

Benefits of Conveyor Belt Wiper Blades

- Efficient removal of fines, sand, gravel, and bulk solids;

- Reduced belt wear, material carryback, and dust for safer operation;

- High-wear polyurethane blades for longer service life;

- Quick, easy installation and lower maintenance costs;

- Custom sizes and profiles available for OEM or custom conveyors.

Application Industries

- Mining and quarrying conveyors;

- Aggregate and sand handling systems;

- Packaging and logistics conveyors;

- Food processing and clean conveying applications;

- OEM conveyor manufacturing.

Replacement Wiper Blades & Custom Solutions

- Product Specifications

- Gallery

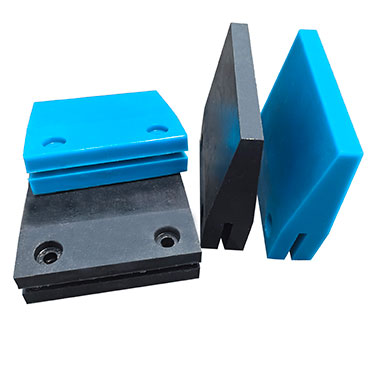

| Specification | Description / Options |

| Material | Polyurethane, Urethane |

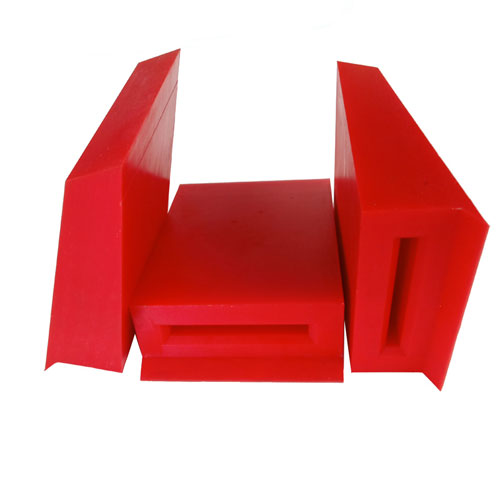

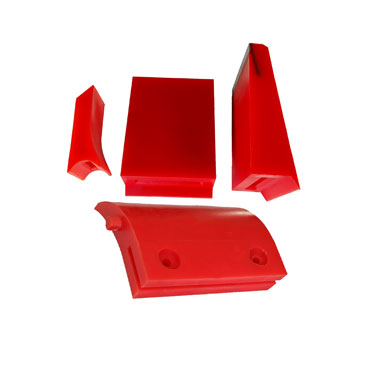

| Blade Type | Single-sided wiper, double-sided wiper, light-duty, medium-duty |

| Length / Width | Customizable to match conveyor belt width (standard and OEM sizes available) |

| Thickness | 6–25 mm (depending on duty and application) |

| Hardness (Shore A) | 70–95 Shore A (flexibility vs abrasion resistance options) |

| Temperature Range | -40°C to 80°C (-40°F to 176°F) for standard polyurethane; high-temperature grades available |

| Mounting Method | Bolted onto conveyor structure; compatible with primary/secondary wiper systems |

| Duty Type | Light-duty, medium-duty, industrial dust control |

| Applications | Packaging, logistics, food processing, bulk material handling, aggregates, mining |

| Replacement / OEM Compatibility | Custom urethane replacement blades available to match OEM belt wipers |

| Key Features | Abrasion resistant, flexible, long service life, reduces carryback, prevents belt wear, easy installation |

Related Products

Custom Polyurethane Conveyor Belt Wiper Blades

Looking for durable, custom-molded polyurethane conveyor belt wiper blades? Our OEM and ODM solutions provide precise hardness control, abrasion resistance, and tailored profiles to fit your conveyor system.

Contact our technical team today for fast quotations, material recommendations, and tailored blade designs.

Conveyor belt wiper blades (also called belt wipers, polyurethane wiper blades, or urethane wiper blades) are designed for light-to-medium duty cleaning. They gently remove fines, dust, sand, or small carryback.

Use wipers when:

- Heavy bulk material removal is not required;

- Conveyor handles powders, packaging materials, or small aggregates;

- You want to protect belts from wear while maintaining efficient material flow;

- For heavy or sticky materials, consider scraper blades or a multi-stage cleaning system.

Replace wiper blades when you notice:

- Persistent fines or dust remaining on the belt;

- Visible blade wear or cracks;

- Uneven wiping or reduced cleaning efficiency;

- Frequent belt contamination or carryback;

- Regular inspection prevents belt damage, buildup under rollers, and dust dispersal.

Yes. We provide custom polyurethane wiper blades and replacement belt wiper blades that fit standard belt-cleaner frames and OEM specifications. Customizations can include:

- Exact belt width and cleaner type;

- Blade thickness, hardness, and profile;

- Mounting method and frame compatibility;

- This ensures a precise retrofit for improved performance and longer service life.

Wiper blades excel with:

- Dust,

- Fines,

- Light materials,

For abrasive, wet, or sticky bulk materials (e.g., ore, wet clay, high-abrasion rock): Wipers may wear quickly or underperform; Consider heavy-duty scraper blades or a scraper + wiper multi-stage system.

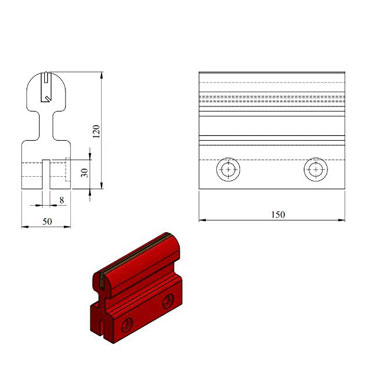

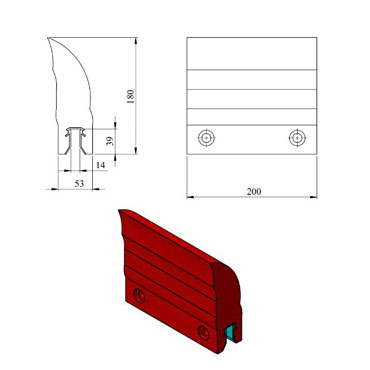

To ensure an exact fit and optimal performance, please provide:

- Drawings or sketches of the existing scraper or wiper blade;

- Cross-sectional dimensions (thickness, width, length, profile shape and size, radius, etc.);

- Belt width and cleaner mounting details;

- Material or hardness requirements (if known);

Our technical team will:

- Replicate your existing blade;

- Recommend suitable polyurethane grades;

- Provide a quotation and production lead time;

- This process ensures your replacement blade matches or exceeds OEM performance, extending belt and system life.