Custom Molded Urethane & Polyurethane Products for Industrial Applications

Looking for durable, high-performance components tailored to your exact needs? Our custom molded urethane and polyurethane products deliver precision, strength, and versatility across industries. From heavy-duty mining equipment to automotive components, we design and manufacture pu parts that outperform traditional rubber, plastic, and metal in demanding environments.

Our custom molded polyurethane solutions provide exceptional durability, abrasion resistance, and impact protection for industrial, automotive, and marine applications. We tailor our polyurethane products to your exact specifications or design drawings to meet your exact requirements, ensuring reliable performance, longer equipment life, and reduced maintenance costs.

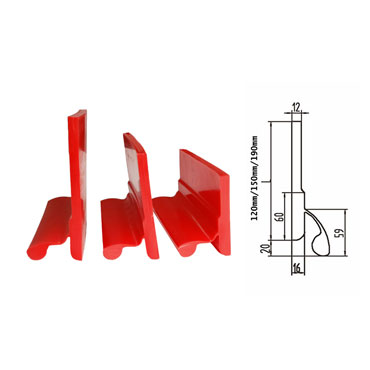

Conveyor Belt Cleaning & Blade Replacement Accessories

Conveyor belt cleaning and blade replacement accessories designed to maintain efficient material flow, reduce carryback, minimize downtime, and extend equipment life, including durable mounting hardware, tensioners, clamps, and easy-fit replacement components.

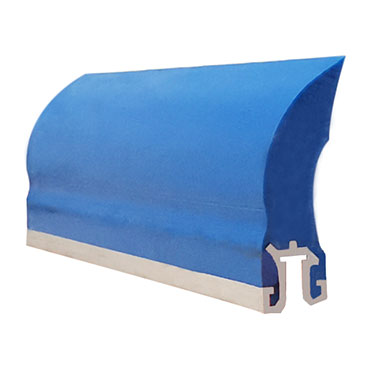

Heavy-duty polyurethane scraper blades for aggressive removal of bulk carryback. Reduce spillage, belt wear, and downtime while ensuring reliable operation in mining, quarry, and high-load conveyors.

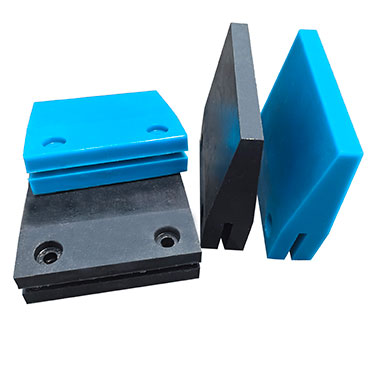

Flexible polyurethane wiper blades for light-to-medium duty belt cleaning. Gently remove surface material to prevent buildup, protecting belts and maintaining smooth operation in packaging, food, and logistics conveyors.

Durable polyurethane scraper blades engineered for aggressive material removal. Reduce carryback, resist abrasion, and provide reliable conveyor cleaning in demanding bulk-handling and industrial applications.

V Plough scrapers, installed on the return side of conveyor belts, sweep loose material off the inside surface to prevent buildup. Durable polyurethane blades self-adjust, protecting belts and splices while ensuring efficient operation in mining, food processing, and industrial conveyors.

Heavy-duty head pulley scrapers for aggressive bulk carryback removal. Protect belts and equipment, reduce spillage, and maintain efficient operation in mining, quarrying, and high-load conveyor systems.

Fine-cleaning scrapers for residual material after primary scrapers. Minimize spillage, dust, and belt wear, ensuring smooth, efficient operation in high-load mining and industrial conveyors.

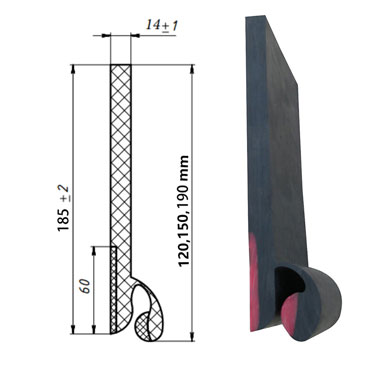

Conveyor Skirting & Sealing Systems

Conveyor Skirting & Sealing Systems provide complete dust control and material containment solutions, reducing spillage, protecting conveyor belts, improving workplace safety, and extending equipment life in demanding bulk material handling environments.

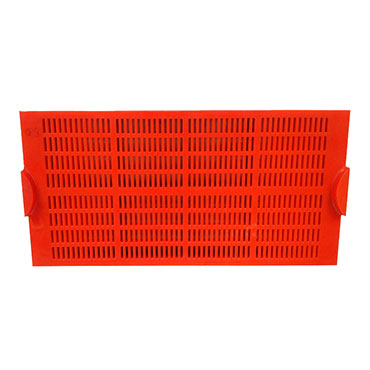

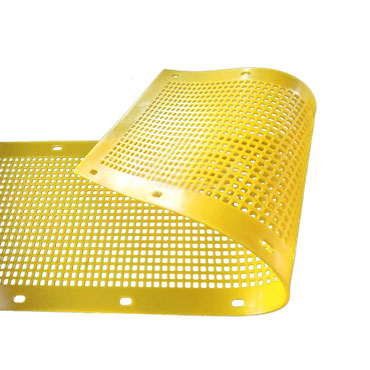

Screening & Separation Media

Optimize your screening operations with polyurethane screen panels and mesh. These durable PU screen panels offer high resistance to abrasion and impact, delivering consistent performance in mining, aggregate, and industrial separation processes.

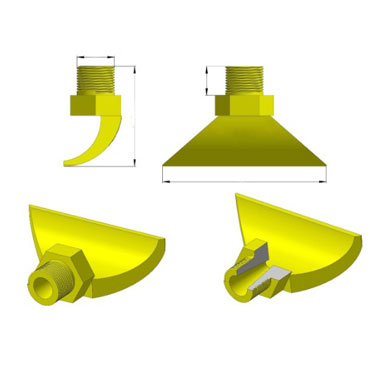

Fluid Handling & Spray Systems

Our polyurethane spray nozzles and custom urethane nozzles provide precise fluid control, resistance to wear, and long service life in high-pressure or abrasive environments.

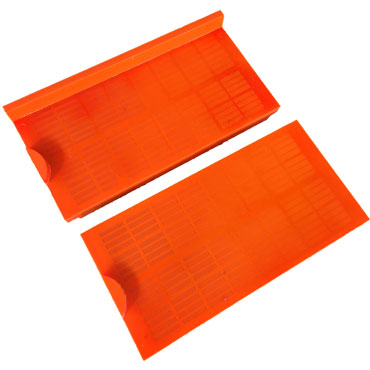

Antistatic Polyurethane Turnover Boxes for Handling Polysilicon Materials

Polyurethane turnover boxes are ideal for the photovoltaic midstream industry—serving ingot/rod makers, wafer-processing plants, and silicon recyclers—because they provide durable, chemical-resistant, lightweight, anti-static, and automation-ready protection for fragile or irregular silicon materials.

Subsea & Offshore Cable Protection Systems

Protect offshore and underwater cables with bend restrictors, bend stiffeners, J-tube seals, and subsea cable protection tubes. Our custom molded urethane components prevent mechanical stress and environmental damage in subsea applications.

Key Benefit of Custom Molded Urethane

Withstands abrasion, chemicals, and high-load conditions.

Protects sensitive equipment and extends service life.

Available in various shapes, hardness levels, and reinforced materials.

Reduces downtime, maintenance, and replacement costs.

Why Choose Custom Molded Polyurethane Products?

- Reduce Downtime: Long-lasting components mean fewer replacements and less maintenance.

- Save Costs: Durable polyurethane outperforms rubber, plastic, and metal alternatives.

- Get Exactly What You Need: From shape and size to hardness to color tailored to your specifications.

- Expert Molding and Prototyping: We offer a variety of polyurethane molding processes to ensure feasibility and cost-effective solutions.

- Reliable Supply: From design prototypes to mass production, we ensure stable delivery times, and make it simple to get the right solution fast.

Custom Molded Urethane Industries & Applications

Our custom polyurethane products are trusted by businesses that demand reliability and durability.

- Automotive & Transportation – Custom bushings, seals, pads, bumpers

- Mining & Heavy Equipment – Impact bumpers, vibration dampeners, wear parts

- Industrial Manufacturing – Conveyor rollers, protective pads, custom-molded machine parts

- OEM Components – Specialized parts designed to fit seamlessly into your equipment and projects.

Our Custom Polyurethane Molding Process

We specialize in custom polyurethane and urethane molding, ensuring that each product meets strict performance and quality standards. From design assistance and material selection to prototyping and final production, we work with you every step of the way to create components that solve real-world challenges.

Choose from a range of:

- Hardness levels (20 Shore A to 80 Shore D)

- Material formulations for abrasion, chemical, or temperature resistance

- Custom colors and finishes.

Our Range of Custom Molded Urethane Products

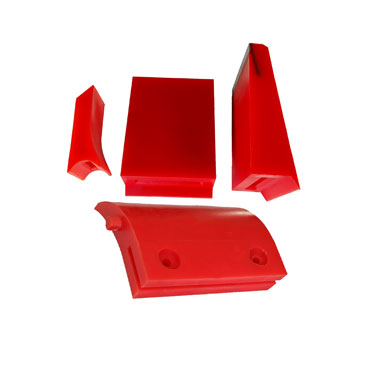

Custom Urethane Bumpers – High-impact resistance for mining and machinery.

Polyurethane Rollers & Wheels – Precision-molded for conveyors and equipment.

Custom Urethane Pads & Seals – Long-lasting protection against wear and abrasion.

Cast and Molded Polyurethane Components – Tailored designs for OEM and industrial applications.

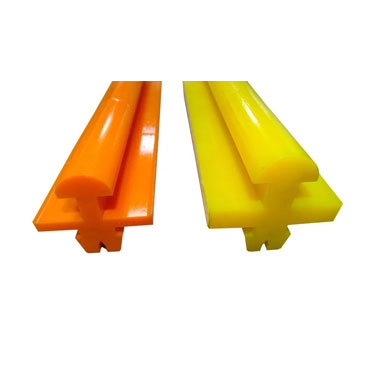

Custom Extruded Polyurehtane Profiles- Sealing strips,food processing and conveyor machinery application.

Marine Towing & Rope Protection

Protect ropes, wires, and towing equipment with towing wire protectors, rope protectors, and polyurethane towing shoes. Designed for harsh marine environments, these components extend equipment life and improve operational safety.

Custom molded polyurethane protects wires and cables from abrasion and impact during towing operations, reducing maintenance and ensuring safe, reliable handling.

Wear-resistant towing shoes minimize friction and prevent damage to ropes and cables. Custom molded for precise fit and long-term operational efficiency.

Safeguard ropes from chafing, abrasion, and environmental damage. Built from high-quality custom urethane products, they extend rope life and reduce downtime.

Durable and flexible, these protectors enhance safety and minimize maintenance costs in industrial and marine towing applications.

Provide robust rope and cable protection during heavy-duty operations. Custom molded for durability, these sleeves reduce friction, prevent damage, and extend service life.

Custom Moulded Polyurethane Products Company -Lisen

- Gallery

- Custom Polyurethane Products

- Polyurethane Raw Material TDS

Our custom molded urethane and custom moulded polyurethane products are engineered for high-performance applications where precision, strength, and durability matter most. With expertise in custom polyurethane molding and custom urethane molding, we provide Custom Polyurethane Products and Custom Urethane Products tailored to your exact requirements.

| Property | Specification / Options |

| Material Options | Multiple custom polyurethane formulations for abrasion resistance, impact strength, and chemical stability |

| Hardness Range | 20 Shore A (soft elastomers) to 80 Shore D (rigid plastics) |

| Design Flexibility | Complex geometries, custom sizes, colors, and finishes available |

| Load & Impact Strength | High load-bearing capacity and superior impact resistance |

| Temperature Resistance | –40°C to +80°C, High-Performance Grades (special formulations): up to +120°C continuous. |

| Wear Resistance | Exceptional abrasion resistance for longer service life |

| Applications | Industrial, automotive, marine, mining, and heavy equipment |

Polyester polyol/TDI series prepolymer

| Model | D3136 | D3145 | D3160 |

| NCO content / % | 3.6±0.1 | 4.5±0.2 | 6.0±0.2 |

| State of matter At 20℃ | White waxy solid | White waxy solid | White waxy solid |

| MOCA 100g prepolymer dosage /g | 10.5 | 13.2 | 17.2 |

| Viscosity(85℃)/ mpa * s | 1800 | 1200 | 900 |

| Mixing Temperature /℃(prepolymer/MOCA) | 85/120 | 80/120 | 75/120 |

| Gel time /min | 9 | 7.5 | 5 |

| Post vulcanization time (100℃)/h | 10 | 10 | 10 |

| Hardness ( shore A) | 85±1 | 91±1 | 96A±1 (54D) |

| 100% constant tensile stress /MPa | 4.2 | 6.7 | 11.5 |

| 300% constant tensile stress /MPa | 8.3 | 12.5 | 21.3 |

| Tensile strength /MPa | 48 | 52 | 55 |

| Elongation at break / % | 670 | 610 | 530 |

| Tear strength (right angle) /(KN/m) | 75 | 95 | 124 |

| Tear strength (pants type) /(KN/m) | 34 | 42 | 49 |

| Rebound /% | 39 | 32 | 33 |

| Density (25℃)/(g/cm) | 1.26 | 1.27 | 1.29 |

| wearing out by friction mm³ | 40 | 48 | 57 |

Polyether polyols PTMG series prepolymer

| Model | D2135 | D2142 | D3160 |

| NCO content / % | 35±0.1 | 4.2±0.2 | 6.2±0.2 |

| State of matter At 20℃ | White waxy solid | White waxy solid | White waxy solid |

| MOCA 100g prepolymer dosage /g | 10 | 12.1 | 18 |

| Viscosity(85℃)/ mpa * s | 1200 | 750 | 480 |

| Mixing Temperature /℃(prepolymer/MOCA) | 85/120 | 85/120 | 80/120 |

| Gel time /min | 11 | 10 | 6 |

| Post vulcanization time (100℃)/h | 10 | 10 | 10 |

| Hardness ( shore A) | 85±2 | 90±1 | 95A±1 (49D±2) |

| 100% constant tensile stress /MPa | 5.4 | 7.5 | 12.8 |

| 300% constant tensile stress /MPa | 9.6 | 14.1 | 36.3 |

| Tensile strength /MPa | 27 | 33 | 48 |

| Elongation at break / % | 550 | 500 | 350 |

| Tear strength (right angle) /(KN/m) | 65 | 78 | 95 |

| Tear strength (pants type) /(KN/m) | 21 | 28 | 33 |

| Rebound /% | 61 | 54 | 47 |

| Density (25℃)/(g/cm) | 1.07 | 1.09 | 1.13 |

MDI series prepolymer

| Model | D3560M |

| NCO content / % | 6.0 |

| Viscosity(80℃)/ mpa * s | 1780 |

| D3560M : D3575-C | 100:6.1 |

| Gel time /min | 8-11 |

| Post vulcanization time (100℃)/h | 48 |

| Hardness ( shore A) | 83±3 |

| Tensile strength /MPa | 46 |

| Elongation at break / % | 580 |

| Tear strength (right angle) /(KN/m) | 82 |

| Rebound /% | 38 |

| Density (25℃)/(g/cm) | 1.2 |

Get Your Custom Molded Urethane & Polyurethane Solution Today

Looking for a reliable partner to deliver custom molded urethane solution and polyurethane products that match your exact requirements? We specialize in custom polyurethane molding, providing high-performance components designed for industrial, automotive, mining, marine, and heavy equipment applications.

From Custom Polyurethane Products like rollers, wheels, bumpers, and seals to custom urethane parts built to your drawings, we ensure every part is engineered for durability, precision, and long-lasting value.

Request a Quote Today and let us help you design and manufacture the right solution for your business.

Custom molded urethane is a versatile elastomer known for its exceptional abrasion resistance, impact strength, and flexibility. Unlike metals or plastics, urethane can be tailored in hardness, color, and formulation, making it ideal for applications requiring durability and precision.

Custom polyurethane molding involves casting liquid polyurethane into molds to create parts with precise dimensions and desired properties. This process allows for the production of complex shapes and varying hardness levels, catering to diverse industrial needs.

Selecting the appropriate durometer depends on the specific demands of your application. Softer durometers (Shore A) offer flexibility and cushioning, while harder durometers (Shore D) provide rigidity and wear resistance. Our team can assist in determining the optimal hardness based on factors like load, speed, and environmental conditions.

Yes, custom urethane products can be machined, especially those with hardness ratings above 70 Shore A. This allows for precise modifications to meet specific tolerances or design requirements.

Absolutely. We offer comprehensive design support as your idea or specification and material selection, to ensure your custom urethane products meet performance and durability standards.

We need detailed information about your project, including:

- Application and operating conditions

- Required dimensions and tolerances

- Estimated order quantity

- Any specific material or color preferences

- Our team will review your requirements and provide a tailored quote promptly.