Custom Urethane Bushings

LISEN’s custom urethane bushings are precision-engineered to meet your exact size, hardness, and performance requirements. Made from high-quality polyurethane, they deliver excellent vibration damping, shock absorption, and wear resistance—outperforming traditional rubber or plastic alternatives. Ideal for OEM machinery, automotive suspensions, and heavy-duty industrial equipment, these bushings ensure reliable operation and extended service life.

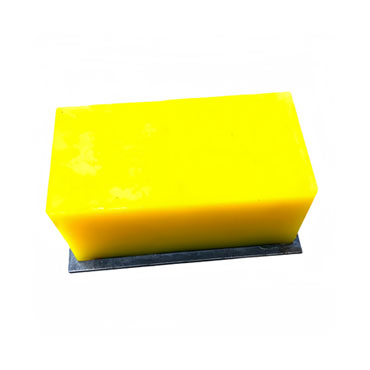

Custom-Made Polyurethane Bushings

Why Choose Custom Urethane Bushings

When standard bushings can’t meet your performance requirements, LISEN’s custom polyurethane bushings deliver precision-engineered solutions tailored to your exact application.

- High wear and impact resistance – Our urethane bushings withstand constant movement, shock, and heavy loads without cracking or deformation.

- Enhanced vibration and noise control – Polyurethane’s elasticity effectively isolates vibration, ensuring quieter, smoother operation.

- Oil, chemical, and abrasion resistant – Ideal for harsh industrial environments or high-performance automotive systems.

- Custom hardness options – Available in a wide range of durometers (A60–D75) to match specific load and damping requirements.

- Precision molded or machined – Manufactured to tight tolerances for exact alignment and consistent performance.

Advanced Molding & Casting Capabilities

LISEN utilizes advanced urethane molding and casting technologies to manufacture bushings with precise geometry, uniform hardness, and outstanding performance consistency. Available options include:

- Molded Urethane Bushings – Custom-shaped designs, optionally bonded to metal sleeves for added support.

- Cast Polyurethane Bushings – Ideal for large-format, heavy-duty, or high-load applications.

- Custom-Made Bushings – Engineered for prototypes, equipment upgrades, and specialized operating environments.

- Every product is made using premium, mine-duty polyurethane elastomers, ensuring superior durability, flexibility, and long-term operational stability across industrial, automotive, and heavy-equipment applications.

Polyurethane Bushing Manufacturers

- Product Specifications

- Gallery

Custom Poly Bushings vs. Rubber Bushings

- Compared with rubber or plastic, urethane bushings offer: Up to 5× longer service life under dynamic stress.

- Tight tolerance control for precise installation.

- Excellent load-bearing capacity without deformation.

- Resistance to oils, fuels, ozone, and abrasion.

- That means less downtime, better vibration control, and a more reliable operating system.

Technical Data — Custom Urethane Bushings

| Specification | Details |

| Product Name | Custom Urethane Bushings / Custom Polyurethane Bushings / Custom Poly Bushings |

| Material | High-performance cast polyurethane elastomer (PU) |

| Hardness Range (Shore A) | 40A – 95A (customizable) |

| Available Grades | Soft (A40–A60): Vibration absorptionMedium (A70–A85): Balanced flexibilityHard (A90–A95): Maximum load resistance |

| Color Options | Standard: Natural Amber, Red, BlackCustom colors available |

| Manufacturing Process | Precision urethane casting or injection moldingOptional metal bonding (steel, aluminum, stainless steel) |

| Tolerance | ±0.05 mm (machined and finished) |

| Operating Temperature | Continuous: –40°C to +90°CIntermittent: up to +120°C |

| Tensile Strength | Up to 50 MPa (varies with hardness) |

| Elongation at Break | Up to 500% |

| Compression Set | <10% (excellent recovery under repeated compression) |

| Abrasion Resistance | 5–10× longer lifespan compared to rubber bushings |

| Chemical Resistance | Excellent resistance to oils, greases, ozone, UV, mild acids, and solvents |

| Load Capacity | High static and dynamic load resistance |

| Applications | Automotive suspension, industrial machinery, mining, construction, agricultural, and OEM applications |

| Customization Options | Custom size, shape, grooves, hardness, color selection, metal bonding or sleeve inserts |

| MOQ & Production Volume | Low-volume prototypes or high-volume OEM production available |

| Quality Assurance | 100% inspection for dimensional accuracy and material consistency |

Applications of Custom Urethane Bushings

- Our urethane bushings are trusted by manufacturers and engineers across industries for their performance and versatility:

- Automotive & Off-Road Vehicles: Suspension, shock absorber, and drivetrain bushings.

- Industrial Machinery: Load-bearing and vibration isolation mounts.

- Mining & Construction Equipment: Heavy-duty wear-resistant joints and pivots.

- Agricultural & Forestry Equipment: Flexible, oil-resistant couplings and mounts.

- OEM Manufacturing: Textile yarn production line shaft bushings with polyurethane, Custom fitment bushings for new product designs or retrofits.

- Each bushing ensures smoother operation, longer service intervals, and reduced maintenance costs.

Related Products

Request a Custom Bushing Solution

As a specialized PU Bushes Manufacturer, We manufacture custom urethane bushings for OEM, automotive, and industrial equipment. Precision-molded polyurethane bushings deliver superior wear resistance, vibration isolation, and long service life.

Need a custom urethane bushing for your machinery or vehicle? Send us your drawings, samples, or specifications—we’ll design and manufacture the ideal solution for your performance goals.

Custom urethane bushings are engineered polyurethane components made to your dimensions and hardness. Choose them when you need superior wear resistance, better load capacity, improved vibration damping, and longer life than rubber or metal can provide.

Send your PDF drawing or a sample plus required hardness, operating temperature, and load data to our sales team. We’ll confirm manufacturability, propose materials/process, and provide a fast, itemized quote.

Yes. We routinely bond PU to steel, stainless, and aluminum sleeves using mechanical or chemical bonding methods. Tell us the metal type and load conditions so we can specify the correct bonding process.

We manufacture any geometry: rings, sleeves, flanges, stepped blocks, bonded metal sleeves, and complex machining. Hardness ranges typically from Shore A40–A95, customized per application for vibration, load, or stiffness requirements.

Typical continuous range is –40°C to +80°C (intermittent to +120°C). Standard PU resists oils, fuels, greases, ozone and many solvents. For aggressive chemicals or higher temps we’ll recommend a specific PU formulation.