Machining Polyurethane

Machining polyurethane involves cutting, turning, drilling, or milling solid polyurethane stock or pre-cast parts into precise shapes and dimensions. This process allows for tight tolerances, complex geometries, and custom features that meet demanding application requirements.

Key advantages:

- High dimensional accuracy and consistent tolerances;

- Smooth surface finishes and precise geometries’

- Custom hardness, flexibility, and chemical resistance;

- Ideal for bushings, rollers, seals, gaskets, and wear components;

We machine polyurethane, urethane, and polyurethane bushings, providing custom solutions for precise, high-performance components. We serve industries where dimensional accuracy, durability, and consistent performance are essential.

Whether your parts are used in industrial machinery, automotive, material handling, or mining, we deliver tailored machined polyurethane components that meet your exact specifications.

Our Cast Polyurethane Post-Processing Capabilities

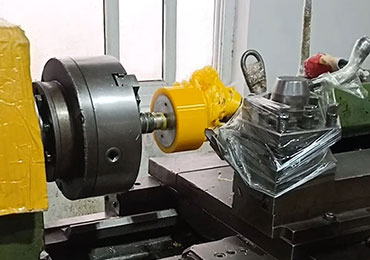

- Custom Polyurethane Bushings – Turned or milled to exact dimensions for automotive, industrial, or machinery applications.

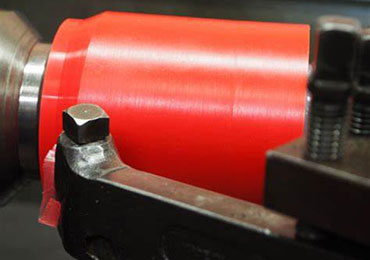

- Rollers & Cylinders – Precision-machined for conveyors, packaging, and processing equipment.

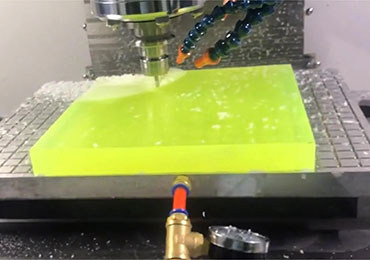

- Sheets, Rods, and Tubes – Cut, drilled, or milled to specification.

- Complex Shapes & Features – Slots, grooves, threads, or internal cavities.

- Low-Volume & High-Volume Production – From prototypes to full production runs.

- Surface Finishing – Polishing, chamfering, or custom treatments for smooth operation.

Advantages of Machined Polyurethane Components

- Superior wear resistance and durability compared to rubber or plastic;

- Customizable material properties for abrasion, impact, or chemical resistance;

- High-precision components for machinery, automotive, and industrial applications;

- Cost-effective alternative to metal parts in certain applications;

- Reduces operational downtime with high-quality, reliable components.

Quality Control for High-precision Polyurethane Components

We ensure every machined polyurethane part meets strict quality standards:- Dimensional inspection for exact tolerances;

- Hardness and performance testing for functional requirements;

- Surface finish verification for smooth operation;

- Process monitoring to maintain consistency and reliability.

Case of Machining Polyurethane Parts

Applications of Machined Polyurethane

Why Choose Us?

As a trusted custom polyurethane manufacturer, we provide:

- Expertise in precision machining of urethane components;

- Flexible solutions for custom shapes, sizes, and material properties;

- End-to-end support from design to full-scale production;

- Reliable delivery, competitive pricing, and proven quality;

Polyurethane Machining Process

- Step 1 – Material Selection & Preparation, Choose the appropriate polyurethane formulation (hardness, flexibility, abrasion resistance).Cut raw stock (sheets, rods, tubes, or pre-cast blocks) to manageable sizes.

- Step 2 – Precision Machining,Turn, mill, drill, or cut the polyurethane to create custom shapes and dimensions.Produce complex features like grooves, slots, threads, or cavities as required.

- Step 3 – Surface Finishing,Chamfer, polish, or smooth surfaces for optimal performance.Ensure the finish meets functional and aesthetic requirements.

- Step 4 – Quality Inspection, Verify dimensions, tolerances, and surface finish.Test hardness, wear resistance, and other material properties.Confirm performance for application-specific conditions.

- Step 5 – Delivery & Installation,Pack and deliver ready-to-use machined polyurethane parts.Include documentation for quality assurance and traceability.

Machining polyurethane involves cutting, turning, drilling, or milling solid polyurethane to create precise components like bushings, rollers, and custom profiles.

- High dimensional accuracy and tight tolerances;

- Smooth surface finishes for optimal performance;

- Customizable hardness, flexibility, and chemical resistance;

- Superior wear and impact resistance compared to rubber or plastic.

Yes. We tailor bushing dimensions, hardness, flexibility, and material properties to meet specific industrial or automotive requirements.

Machined polyurethane components are widely used in automotive, industrial machinery, material handling, mining, construction, and consumer products.

Provide drawings, CAD files, or specifications, and our team will deliver a custom quote for your project.

Machining creates precise, complex features from solid polyurethane, while casting forms parts in molds and extrusion produces continuous profiles with uniform cross-sections.