Our Polyurethane Molding Capabilities

We offer custom polyurethane molding services for a wide range of industries, delivering high-quality molded polyurethane products and urethane molded parts that meet demanding application requirements. Our comprehensive capabilities cover every stage of the polyurethane manufacturing process, from material selection to production and quality control.

Raw Material Selection and Handling

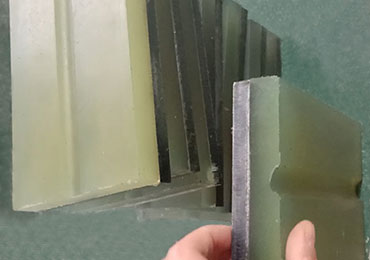

We understand the properties of various polyurethane elastomers and select the ideal formulation to match each product’s requirements. This includes hardness, elasticity, abrasion resistance, chemical resistance, and other performance characteristics. Our team performs careful pre-treatment of raw materials, such as drying, mixing, and blending, to ensure stable and consistent material quality before molding.

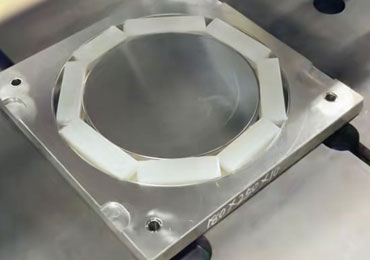

Mold Design and Manufacturing

We design and manufacture molds according to your specifications or technical drawings. Our in-house machining workshop, equipped with CNC machines, wire-cutting tools, and precision equipment, ensures accurate, high-quality molds. This precision guarantees that the final urethane molded parts meet tight tolerances and have consistent performance.

Polyurethane Molding Process Control

Quality Inspection and Control

We implement a comprehensive quality management system to ensure every part meets industry standards. Each customer order is carefully planned to optimize production efficiency and ensure timely delivery.

- Appearance and visual inspection;

- Dimensional measurement and tolerance verification;

- Hardness and mechanical property testing;

- Performance validation for application-specific requirements;

- This rigorous quality control ensures that every molded polyurethane product performs reliably in its intended application.

Customer Service and Technical Support

We provide professional consultation on all aspects of polyurethane molding, including:

- Material selection advice;

- Process recommendations for casting, compression, injection, or extrusion;

- Guidance on product performance and design optimization.

We also offer customized polyurethane molding solutions for products with special shapes, sizes, or performance requirements, as well as small-lot, multi-variety production runs. Our goal is to help customers maximize product performance while reducing costs and improving efficiency.

- Cases of Molded Polyurethane

- Steps of the Polyurethane Molding Process

The common steps in the polyurethane molding process include:

Step 1. Raw Material Selection – Choose polyols, isocyanates, and other raw materials based on the required product performance.

Step 2. Formulation Design – Determine precise ratios of raw materials and select suitable additives to achieve the desired properties.

Step 3. Pre-Mixing Treatment – Pre-mix certain raw materials to ensure uniformity and consistency.

Step 4. Measuring and Mixing – Accurately measure and fully mix the raw materials using specialized equipment.

Step 5. Mold Preparation – Clean the mold and apply a release agent to ensure proper molding and easy demolding.

Step 6. Pouring or Injection – Inject or pour the mixed polyurethane into the prepared mold.

Step 7. Curing Reaction – Allow the material to cure under controlled temperature, pressure, and time conditions.

Step 8. Demolding – Carefully remove the cured part from the mold to avoid damage.

Step 9. Post-Processing – Perform deburring, sanding, trimming, and quality inspections to meet final specifications.

How to Choose the Right Polyurethane Molding Process

Selecting the most suitable polyurethane molding process depends on several key factors:

1.Part Size and Shape – Complex or large parts may require specialized molding techniques.

2.Precision and Surface Quality – High demands for surface finish and dimensional accuracy favor precision casting or injection molding.

3.Physical Properties – Strength, hardness, elasticity, and chemical resistance vary depending on the molding process.

4.Production Volume – High-volume production benefits from automated processes like injection molding, while small-lot or single-piece runs may be better suited to hand pouring or reaction injection molding.

5.Process Characteristics

- Pouring/Casting: Best for simple, large, or thick-walled parts; lower productivity.

- Injection Molding: Offers high precision, complex shapes, and high productivity; mold cost is higher.

- Reaction Injection Molding (RIM): Ideal for large, thin-walled, complex parts; shorter cycle times.

6.Cost Considerations

- Mold Costs: Vary depending on process complexity.

- Material Costs: Different polyurethane formulations (TDI, MDI, NDI, PPDI) have different prices.

- Production Efficiency: Polyurethane types differ in processing difficulty, affecting cycle times and overall efficiency.

Carefully evaluating these factors will help you select the polyurethane molding process that best fits your project requirements.

Why Choose Us for Polyurethane Molding

We deliver high-performance custom polyurethane molded parts with precision, durability, and cost-effectiveness.

- Tailored Materials – Choose polyurethane formulations with the right hardness, elasticity, abrasion, and chemical resistance for your application.

- Precision Molds – In-house mold design and machining ensure complex shapes and consistent quality.

- Expert Process Control – Advanced equipment and skilled operators manage temperature, pressure, and curing for reliable production.

- Versatile Molding Options – Injection, casting, extrusion, compression, centrifugal, and rotational molding for any geometry or volume.

- Cost-Effective & Durable – Optimized processes reduce costs while maintaining product performance and excellent bonding.

- Customer-Focused Support – Guidance on materials, processes, and custom solutions for small or large production runs.

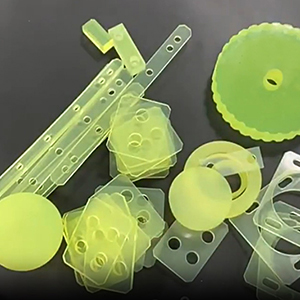

Polyurethane molding is a manufacturing process that forms liquid or solid polyurethane into custom shapes using molds. It allows production of urethane molded parts with precise dimensions, tailored hardness, and desired performance properties.

We produce a wide range of molded urethane products, including rollers, wheels, gaskets, bushings, shock pads, and seals, customized for various industrial, automotive, and consumer applications.

Choosing the right process depends on product size, complexity, production volume, and material requirements. Options include injection molding, casting, compression molding, extrusion, centrifugal, and rotational molding.

Yes, we provide custom polyurethane molding services, tailoring materials, hardness, color, and shape to meet your exact specifications and performance requirements.

Our urethane molded parts serve industries such as automotive, aerospace, food processing, medical, industrial machinery, logistics, and consumer goods.

Using advanced mold design and process control, our molded polyurethane parts achieve tight tolerances, smooth surfaces, and consistent performance, suitable for complex geometries.