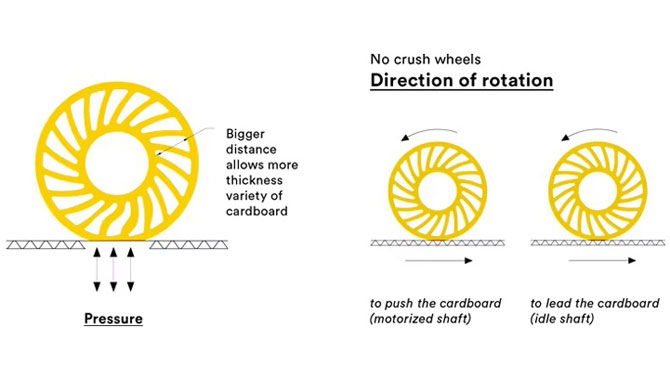

No Crush Wheels

No Crush Wheels and Zero-Crush Wheels are soft, flexible polyurethane wheels designed to apply consistent pressure without damaging products. They’re commonly used in packaging, printing, bottling, and labeling lines to gently guide, compress, or space fragile items.

Polyurethane Non-Crush & Pressure Holding Wheels

Key Features of No Crush Wheels

- High-Durability and resists abrasion;

- Non-Marking, Low Noise;

- Flexible Core Designs- Absorb impact and adapt to product variation;

- Custom Specs Available.

Application of No Crush Wheels - Zero Crush Wheels

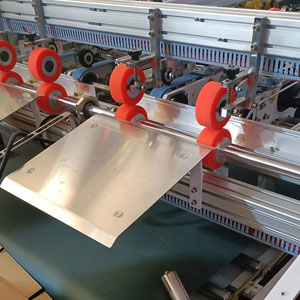

- Packaging & folding Carton Machinery

- Printing & Converting Equipment

- Labeling & Bottling Lines

- Conveyor & Automation Systems

- Industrial Automation OEMs

PU Feeding, Pressing & Measuring Roller Wheels

- Product Specifications

- Gallery

| Specification | Description |

| Outer Diameter | 50 mm – 350 mm (customizable) |

| Inner Bore | Keyed bore, plain bore, or with bearing inserts; size per customer specs |

| Face Width | 10 mm – 100 mm |

| Material | High-performance cast polyurethane or injection polyurethane |

| Hardness (Shore A/D) | 55A – 95A (soft-touch to semi-rigid), custom durometer available |

| Core Options | Aluminum, steel, plastic, or full polyurethane (no core) |

| Color Options | Red, orange, blue, black, translucent, etc. (custom colors available) |

| Temperature Range | -30°C to +80°C (extended range on request) |

| Key Features | Non-crush design, flexible lobe profiles, excellent wear resistance, non-marking |

| Applications | Corrugated packaging lines, labeling, bottling, paper feeding, converting |

| Customization | Profile shapes (star, lobe, radial), hardness, bore type, and dimensions |

Optional for Custom PU Sun Wheels

- Anti-static or conductive formulations

- Oil, grease, and chemical resistance

- Dual Hardness wheels as option.

- Non-marking tread formulation

- Food-grade polyurethane available on request

Related Products

Custom Polyurethane Solutions

We specialize in custom polyurethane molding. Whether you need a new design or a direct replacement, we’ll tailor every detail—material, hardness, core structure, or bore type—to fit your equipment and application.

We use high-performance cast polyurethane with customizable hardness (Shore A 55–95). The wheels can include flexible cores, spider designs, or solid structures depending on the application.

They are the same product type. Different industries use slightly different terminology (e.g., "No-Crush" vs. "Zero-Crush"), but all refer to wheels that offer non-damaging pressure for material handling systems.

Polyurethane offers excellent flexibility, durability, and chemical resistance. Our wheels are non-marking, low-noise, and designed for high wear resistance—making them ideal for sensitive and continuous operation environments.

They’re used in:

- Folding carton and corrugated box machines

- Label applicators and bottling lines

- Material feeding and spacing conveyors

- Printing and laminating equipment

These wheels gently support and transport items without deformation.

Yes. We support sample orders and small-batch production for testing, prototyping, or new line validation. Our team works closely with customers to ensure each wheel performs as intended before scaling production.