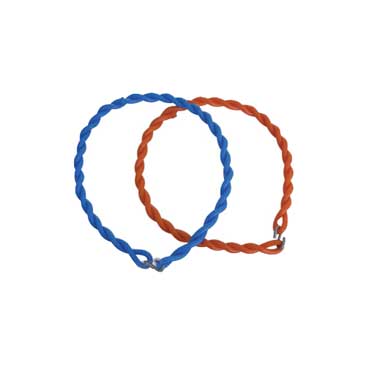

O-Ring Drive Belts

O-Ring drive belts are circular, continuous, seamless drive belts made from polyurethane that function as power transmission belts in automated machines. Their unique O-ring shape allows for smooth, flexible, and efficient power transfer, making them ideal for high-precision and light-duty applications.

Polyurethane O Ring Drive Belt for Conveyor

Key Features & Advantages of O-Ring Drive Belts?

- High durability, resistance to abrasion

- Low maintenance and Cost-effective

- Anti-Static Option Available

- Flexibility and Customizable

Applications of O-Ring Drive Belts

- Conveyor Systems

- Robotics and Automation

- Material Handling

- Printing and Textile Industries

- Food Processing & Packaging

Cast Polyurethane Rings - Urethane Seals O-Ring Supplier

- Product Specifications

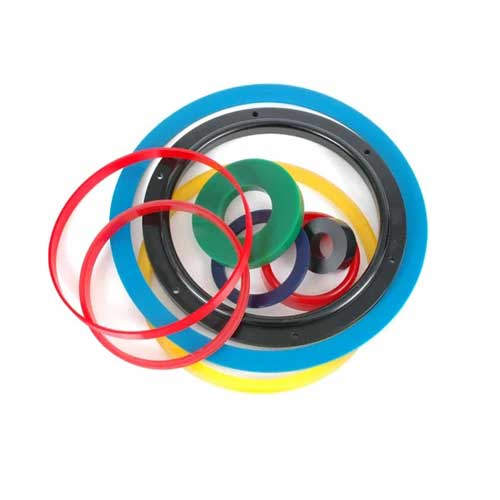

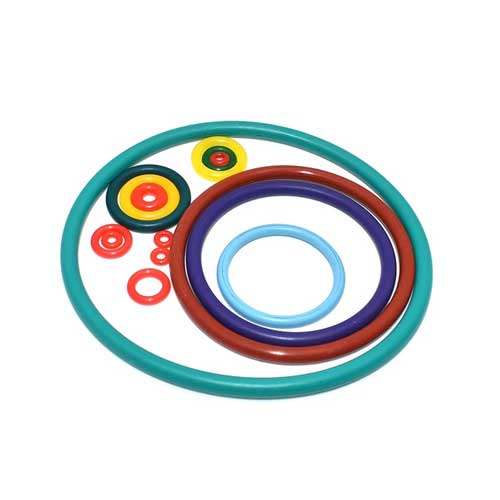

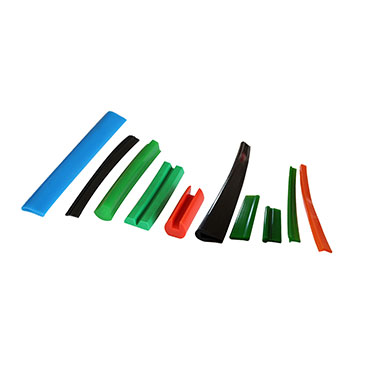

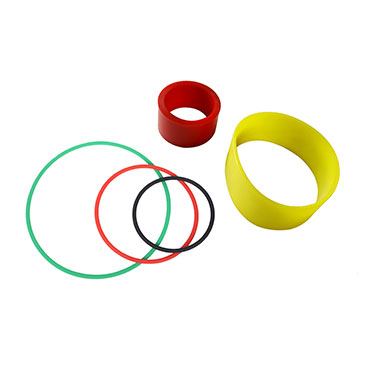

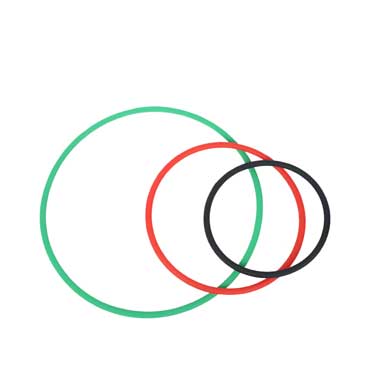

- Gallery

| Specification | Description |

| Material | Solid or Hollow Polyurethane round belts, or reinforced with high-strength fibers (e.g., Kevlar, steel, or polyester) for enhanced durability and tensile strength. |

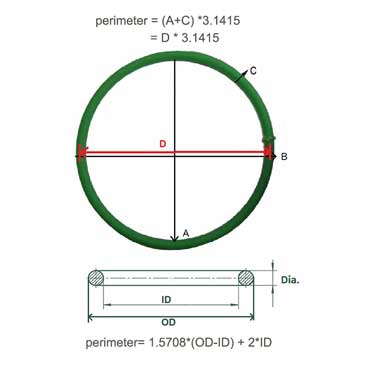

| Cross-Section Shape | O-Ring (round belts, V-belts, Flat belts). |

| Size Range | Available from 3 mm to 100 mm (custom diameters available on request). |

| Hardness (Shore A) | 85A - 90A (custom hardness options based on load and application requirements). |

| Tensile Strength | Typically 30-50 MPa, depending on reinforcement material. |

| Elongation at Break | 300%-600%, depending on reinforcement material and specific design. |

| Temperature Range | -30°C to +80°C (some variations can withstand higher temperatures, up to +120°C). |

| Resistance | Highly resistant to abrasion, UV exposure, oils, chemicals, and ozone. |

| Surface Texture | Smooth (custom textures available for increased grip or specialized applications). |

| Maximum Load | Designed for medium to high-torque applications, depending on the diameter and reinforcement. |

| Joining Type | Available as endless or can be welded or mechanically joined for custom length requirements. |

| Length Options | Custom lengths available, typically offered in rolls or pre-cut lengths (e.g., 30m, 50m, 100m). |

| Applications | Ideal for conveyors, material handling, automated systems, and small machinery in industrial and commercial environments. |

| Compliance & Standards | Meets or exceeds industry standards for quality, durability, and performance in industrial environments. |

Related Products

Why Choose Urethane O-Ring Drive Belts

As a leading manufacturer of polyurethane products, we specialize in providing custom O-Ring drive belts designed for maximum performance. Whether you need extruded polyurethane belts or custom solutions, we have the expertise to deliver high-quality products that will improve your system's efficiency, reduce downtime, and optimize your operations.

O-Ring Drive Belts transmit power by connecting two pulleys. The O-ring shape allows the belt to maintain continuous contact with the pulleys, ensuring efficient, low-friction transfer of energy. They are ideal for low-maintenance, high-speed applications.

Our O-Ring Drive Belts are typically made from polyurethane for enhanced durability, but we also offer rubber-based belts for specific requirements. Polyurethane belts provide superior abrasion resistance, flexibility, and chemical resistance, making them suitable for harsh environments.

Polyurethane O-Ring Drive Belts typically last 2-3 times longer than traditional rubber belts. Their abrasion resistance and low-maintenance design ensure they provide long-lasting performance with minimal wear, reducing the need for frequent replacements.

Yes! We provide custom solutions for O-Ring Drive Belts in terms of diameter, hardness, length, and material type. Whether you need a specific size or reinforced version, we offer tailored solutions to meet your application’s requirements.

Yes! O-Ring Drive Belts can be joined or welded on-site if needed. We provide joining kits for customers who require custom lengths or need to repair belts quickly, minimizing downtime and ensuring continuous operation.