Polycord Belt

Polycord belts are reinforced polyurethane drive belts, made with high-strength fibers like polyester, nylon, Kevlar, or steel. Specifically designed for high-strength transmission applications, they provide exceptional tensile strength, flexibility, and wear resistance. These belts ensure efficient power transfer in industrial machines and conveyors, making them ideal for oil-resistant, corrosion-resistant, and abrasion-resistant environments.

Polycord Drive Belt Suppliers and Manufacturers

Key Benefits of Polycord Belts

- Superior Durability

- High strength

- Chemical & Oil Resistance

- Low Maintenance

- Custom Solutions

Applications of Polycord Belts

- Automated Machinery

- Material Handling Systems

- Packaging Lines

- Textile Machinery

- Conveyor Systems

- Power Transmission Systems

- Food Processing Equipment

Reinforced Polycord Belts- Durable Drive Belts Solutions

- Product Specifications

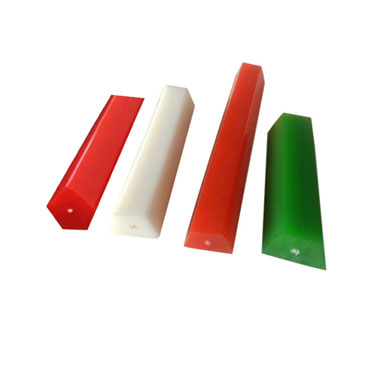

- Gallery

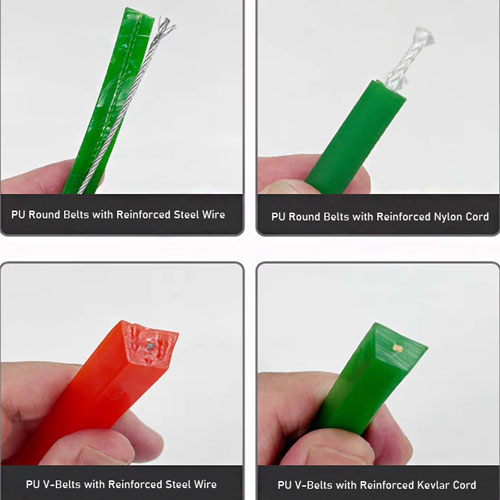

Polycord Round Belt

| Specification | Description |

| Material | Polyurethane round belts reinforced with Kevlar, polyester, or steel for added strength and durability. |

| Cross-Section Shape | Typically round (but can be custom-shaped depending on the application). |

| Diameter Range | 5mm to 20 mm (custom diameters available for specific applications). |

| Hardness (Shore A) | Typically 85A - 90A, but can be customized based on the required flexibility and load. |

| Tensile Strength | Approx. 30-50 MPa depending on the reinforcement and material selection. |

| Elongation at Break | Typically 300%-600% depending on material and reinforcement. |

| Temperature Range | -30°C to +80°C, intermittent operation up to +100°C (higher tolerances available on request). |

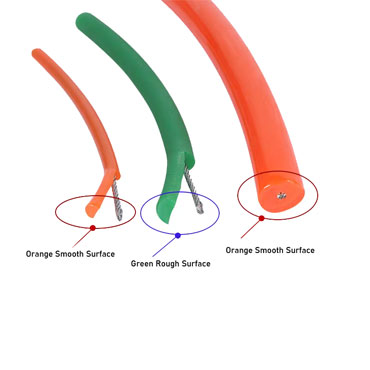

| Color Options | Green, orange, clear, black, or custom colors as per requirements. |

| Resistance | Excellent resistance to abrasion, oil, ozone, and UV radiation. |

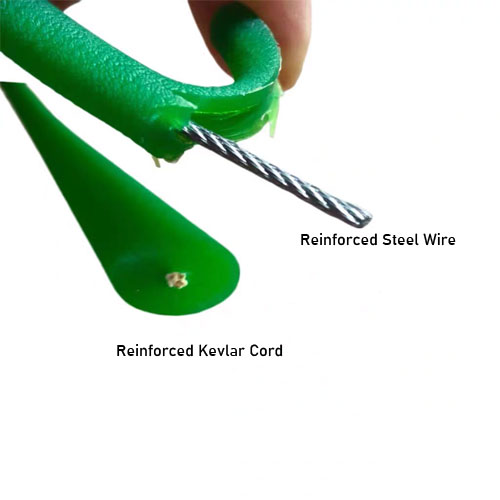

| Reinforcement | Available with internal steel cords, Kevlar, or polyester fibers for high-tension, heavy-duty applications. |

| Surface Texture | Smooth or roughened surfaces, depending on grip and application needs. |

| Joining Type | Endless loops or joined via heat welding (heat-weldable for onsite repairs). |

| Custom Length | Available in custom lengths or coil form (standard lengths: 30m, 50m, or 100m). |

| Core | Can have a reinforced core for added strength, especially for high-tension applications. |

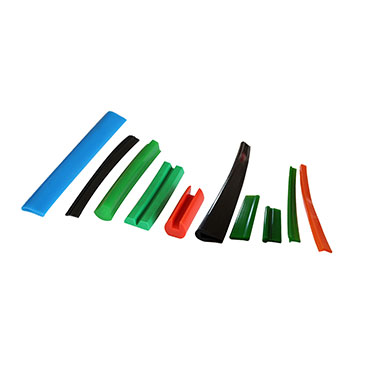

Polycord V-Belt

| Specification | Description |

| Material | Polyurethane v-belts reinforced with Kevlar, steel, or polyester for added strength. |

| Cross-Section Shape | V-shaped (standard sizes such as A, B, C, D, etc.). |

| Width Range | From 6mm, 8mm,10mm,13mm, 17mm,22mm,32mm(custom sizes available). |

| Height Range | From 4mm,5mm,6mm,8mm,11mm,17mm,19mm(custom heights available based on requirements). |

| Hardness (Shore A) | 85A - 90A for standard applications (custom hardness available). |

| Tensile Strength | Approx. 30-50 MPa depending on the reinforcement used. |

| Elongation at Break | Typically 300%-600%, depending on reinforcement material and specifications. |

| Temperature Range | -30°C to +80°C (intermittent up to +100°C for certain materials). |

| Surface Texture | Smooth for enhanced grip and performance. |

| Resistance | High resistance to abrasion, oil, UV, ozone, and chemicals. |

| Joining Type | Endless loop or mechanical joining (depending on application). |

| Custom Lengths | Available in custom lengths or coil form (common lengths: 30m, 50m, 100m). |

| Reinforcement | Can include steel cords, Kevlar, or polyester fibers for added durability. |

Related Products

Our Polycord Belts Advantage

Polycord belts offer a superior alternative to traditional rubber belts, providing long-term reliability, minimal stretch, and consistent performance. They are ideal for applications where conventional belts might stretch, wear out, or slip under pressure.

In short, Polycord belts are the optimal solution for industries needing durable, high-performance, low-maintenance power transmission systems. Let me know if you need any adjustments or further expansion!

Polycord belts offer greater durability, superior wear resistance, and longer service life than rubber belts. They maintain tension and shape under load, perform better in harsh environments (extreme temperatures, oils, and abrasives), and require less maintenance.

Polycord belts typically last 2–3 times longer than traditional rubber belts. Their abrasion resistance and low maintenance requirements make them a cost-effective solution for industries looking to reduce downtime and replacement costs.

Yes, Polycord belts are heat-weldable, We provide butt welding tool kits and overloop welding service as according to your request circumference.

Polycord belts reduce slippage, stretching, and friction, ensuring more efficient power transfer. Their smooth surface and high-strength material help maintain consistent speed and torque, making them ideal for high-speed, high-precision applications like automation systems and robotics.

Common issues include wear and tear, slipping, and misalignment. These can be minimized by ensuring proper tension and alignment, using the right reinforcement for the load, and maintaining regular inspection to identify signs of damage early.