Polyurethane Belt Welding Kit

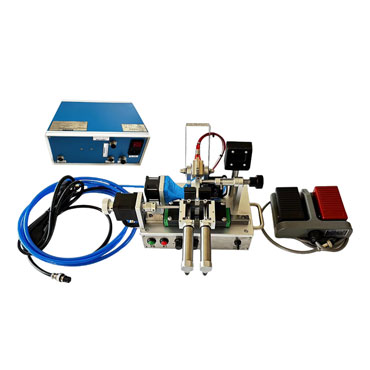

Polyurethane belt welding kits, also called polyurethane welding kits or belt welding machines, weld open PU or polycord belts into O-ring drive belts at any specified length. These kits give OEMs and small manufacturers an efficient solution for on-site narrow belt welding. They extend belt lifespan, improve equipment efficiency, and reduce costly downtime in power transmission, conveyor systems, and automated machinery.

PU Belt Welding Kits and belt welding machine for Industrial Applications

Why Choose Our Polyurethane Belt Welding Kits or Friction-Welding-Machines?

- 1. Our welding tool kits are cost-effective and durability.

- 2. Our soldering irons and clamp are available in a variety of styles, allowing you to freely match the welding tools kits according to your needs.

- 3. Our Belt welding kits easy-to-use and save splicing time.

- 4. Using our welding tool kits, you can welding a strong joints that maintain the strength and durability of PU belts.

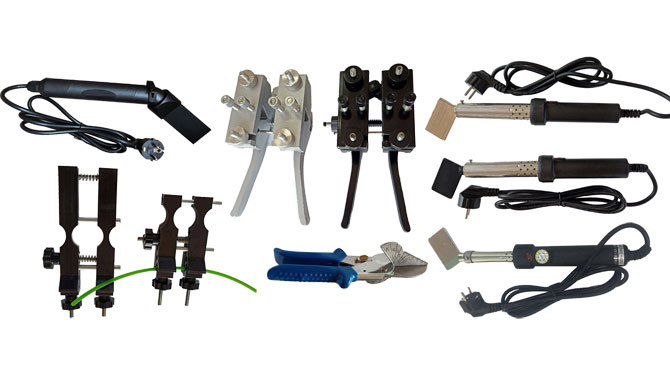

What’s included in Urethane Belt Welding Tool Kits?

- 1. 230V/150W or 110V-245V /500W Constant Temperature Solder Iron, and 230V/200W Adjustable constant temperature 150℃ -400℃ Electric Solder Iron as you options.

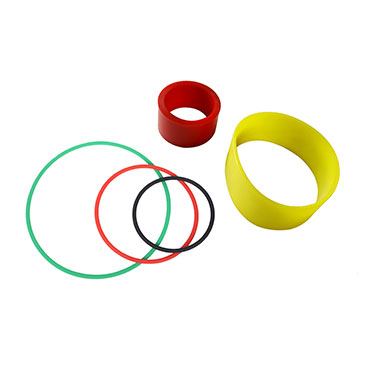

- 2. Aluminum Clamp ( silver or black ) and Lightweight Clamp in different length as options.

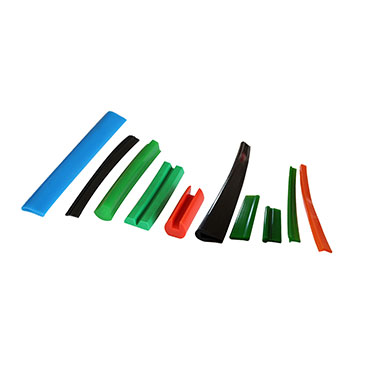

- 3. Vertical /angle Shear Anti-skid Scissors in different color, random delivery.

Polycord and Urethane Belt Joining Solutions

- Product Specifications

- Gallery

| Equipment With | 220/230V Soldering Iron | Welding Clamp | Scissors |

| Selection | Soldering Iron Teflon Coating -Black | Black | Anti-Skid |

| Soldering Iron Teflon Sticking | Silver | Steel | |

| Description | Constant temperature heating | Aluminum | Vertical / Angle shear |

| Specification (mm) | 340Lx 50Wx 85H | 210L x130W x110H | 225Lx 65Wx 60H |

| Net Weight(kg) | 0.70 | 0.80 | 0.40 |

| Application | For all kinds of PU V-belt and Round belt without cord | ||

Polyurethane Belt Joining Step:

- Belt Cutting - Cut the belt according to its circumference. Ensure the cuts are flat at both ends. Keep the belt clean and free of foreign matter, especially oil, dirt, and dust. This will directly affect the joint strength. For PU belts with reinforcing fiber cord, cut bevels at both ends to increase the joint area, ensuring the strength of the joint area.

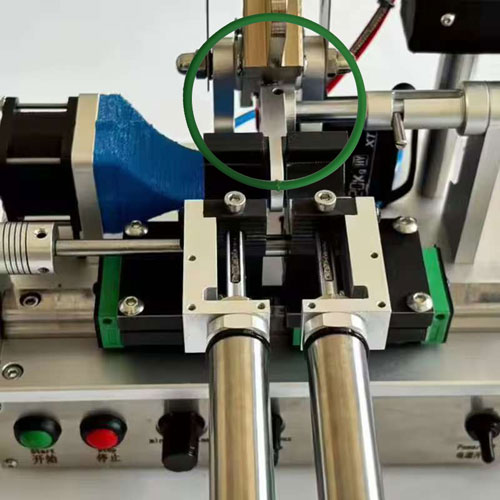

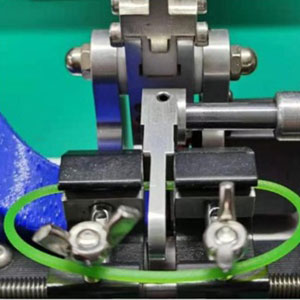

- Belt Clamping - Loosen the four big screws of the aluminum clamp, adjust the height of aluminum plates to put the belt into it.Put the two ends of belt into the locating slot (If the belt size is small, adjust the four small screw of clamp to fit it.), preset protruding length on both ends of the belt, make the two end belt match perfectly.

- Start Welding - Pre-heat the soldering iron, Place the soldering iron between two ends of belt, gently tighten the clamp, make both ends completely touch soldering iron. when PU are melted and effluent approximately 0.5~1mm, take out the soldering iron quickly, fasten the welding clamp by the side screw.

- Remove Belt From Clamp - Natural cooling about 3 minutes, then take off the belt.

- Trim or Polish the Joints - Use trimming shears to repair belt burrs, or use a belt grinder to grind the belt interface to make the interface smoother and more beautiful.

Related Products

Polyurethane Belt Welding Tool Kit Supplier in China

As polyurethane belt welding kit supplier in China, we are committed to providing you with the best quality tools for narrow belt welding and maintenance needs. With fast delivery, custom solutions, and competitive pricing.

Meanwhile, we offer overlap belt welding serive for reinforced polyurethane belts ( like reinforced nylon cord, kevlar cord and steel wire ), which used on higher load applications.

Get in touch with us today to place your order or request a quote. For bulk orders or customized solutions, contact our team for further assistance.

Polyurethane Belt Welding Kit is used to join or repair polyurethane (PU) and polycord belts. It’s ideal for creating customized belt lengths, repairing damaged belts, or joining two ends to form an O-ring drive belt. These kits are commonly used in conveyor systems, automated machinery, and power transmission applications.

The Welding tool Kit offers a fast, cost-effective solution for repairing and joining PU belts on-site. It ensures a secure, reliable joining that increases the lifespan of belts, reduces downtime, and eliminates the need for costly replacement belts.

The kit typically includes a welding tool that uses heat and pressure to melt the edges of a polyurethane belt, allowing them to fuse together. The welding process ensures a strong, seamless connection that can handle the stresses of mechanical and conveyor systems.

The time required to weld a PU belt depends on the belt's diameter and the skill level of the person splicing it. On average, the process takes two to three minutes. The welding tool is easy to operate according to the tool's instructions. Basic training or a few test runs are generally sufficient.

Friction Belt Welders can be connected to round belt and v-belt after frequency adjustment and clamping jaws, and it can be connected to different materials such as PE, PP, PA, PU acrylic. At present, our clamping jaws has 8mm, 10mm, 12mm, 15mm, 18mm diameter round belt, and (A/B/C) v-belt, if you need other types of clamping jaws, we can be customized according to the different needs of customers.