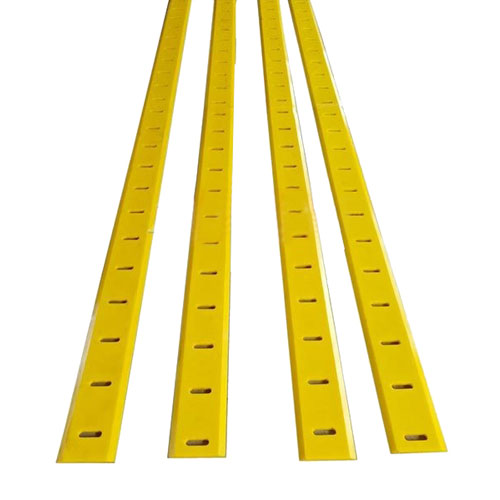

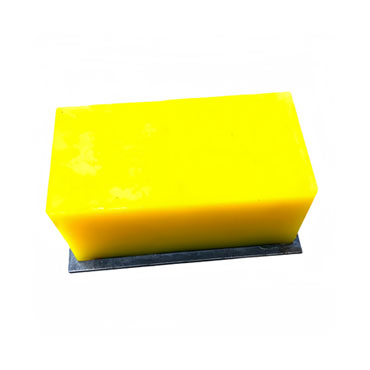

Polyurethane Blades

Polyurethane blades are durable industrial components made from PU or urethane. They scrape, wipe, cut, and clean surfaces while delivering superior wear resistance, flexibility, and long service life. Ideal for replacement or custom OEM use, they match your equipment precisely and reduce downtime caused by frequent blade wear.

Custom-made Wear Polyurethane Blade Manufacturer

Why Choose Polyurethane Blades?

- Longer service life than rubber blades;

- Safer, quieter alternative to metal blades;

- Excellent abrasion, impact, and tear resistance;

- Maintains edge contact without damaging equipment;

- Custom-molded to drawings or samples.

Applications & Industries

- Conveyor systems & material handling;

- Mining, aggregate & cement plants;

- Industrial cleaning equipment;

- Manufacturing & processing lines;

- OEM machinery and retrofit systems.

Custom Capability for Polyurethane Blades

- Product Specifications

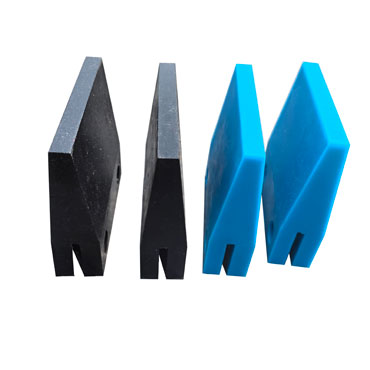

- Gallery

| Specification | Details / Options | Notes / Benefits |

| Material | Polyurethane (PU), Urethane | High abrasion resistance, flexible, long service life |

| Blade Type | Scraper, Wiper, Squeegee, Cutting, Sealing | Select based on application type |

| Length | 100–2000 mm (customizable) | Can be tailored to fit belts, machines, or surfaces |

| Thickness | 3–25 mm | Depending on flexibility, wear resistance, or load |

| Hardness (Shore A) | 60–95 | Balances flexibility and durability for different applications |

| Mounting Options | Bolt-on, Clamp-on, Custom | Fits existing machinery or conveyor systems |

| Color | Standard: Blue, Red, Yellow; Custom | Optional for identification or application-specific coding |

| Operating Temperature | -40°C to 80°C | High-temperature grades available for demanding environments |

| Applications | Conveyor belts, machinery, industrial equipment, flooring | Scraping, wiping, cutting, sealing, cleaning tasks |

| Replacement Compatibility | Works with standard OEM systems | Ensures easy retrofit and minimal downtime |

Related Products

Custom Polyurethane Blades – Made to Match Your Equipment

Need a custom polyurethane blade? Send us your drawing or sample. Our engineering team will recommend the right PU material, hardness, and blade design for your application.

Customization Options:

- Hardness: soft to high-wear grades ( 63~90 shore A);

- Thickness & edge profile;

- Mounting holes, slots, or inserts;

- Molded or machined production.

Polyurethane blades are used for scraping, wiping, cleaning, cutting, or guiding in industrial and commercial systems. Common applications include conveyor belt cleaning, wear protection, material handling, floor squeegees, and OEM machinery.

Polyurethane blades offer higher abrasion resistance than rubber and more flexibility than metal. They reduce belt or surface damage, last longer, and perform consistently in abrasive, wet, or high-load environments.

We manufacture polyurethane scraper blades, wear blades, conveyor cleaning blades, wiper and squeegee blades, cutting blades, and fully custom PU blade profiles for industrial and OEM applications.

Yes. We produce custom polyurethane blades based on your drawings or samples. Blade length, thickness, hardness, profile, and mounting features are tailored to ensure exact fit and OEM compatibility.

To customize or reproduce a blade, we typically need a drawing or sample, overall dimensions, cross-section profile, hardness requirements (if known), and mounting details such as holes, slots, or clamps.