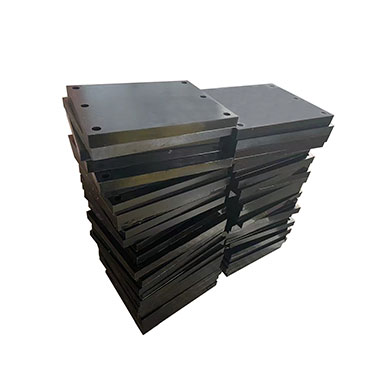

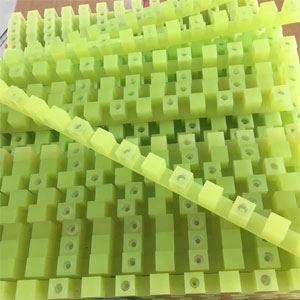

Polyurethane Block

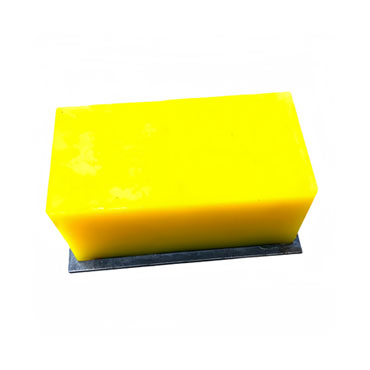

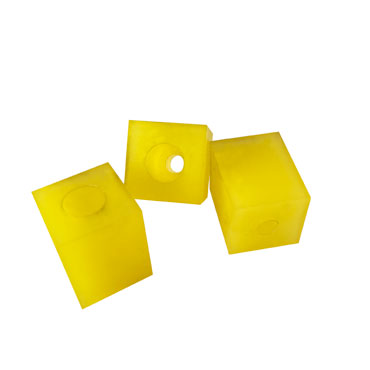

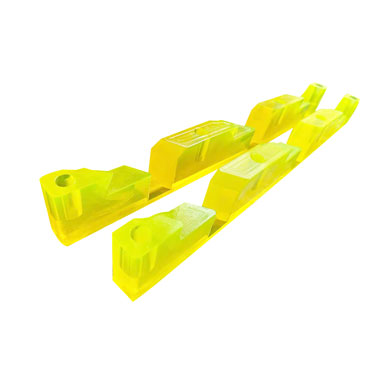

A polyurethane block is a solid PU elastomer for industrial and OEM use. It machines easily into rollers, bushings, spacers, wear pads, and protective components that demand durability, impact resistance, and dimensional accuracy.

Custom Cast & Wear-Resistant PU Blocks

Why Choose Our Polyurethane Blocks?

- Industrial-grade PU materials with high wear and impact resistance;

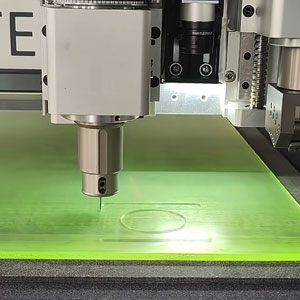

- Fully machinable for custom OEM parts;

- Dimensionally stable and vibration-absorbing;

- Available as solid, cast, elastomer, or wear-resistant blocks;

- Fast RFQ support for custom sizes and batch production;

Applications

- Industrial rollers, bushings, and wear pads;

- Protective components and spacers for heavy-duty machinery;

- Load-bearing OEM parts requiring precision-machined PU;

- High-load, abrasion-intensive assemblies;

- Vibration-damping or impact-absorbing components.

Standard & Industrial Polyurethane Blocks

- Product Specifications

- Gallery

| Specification | Details |

| Material Type | Polyurethane Elastomer (PU) |

| Product Types | Solid PU Block / Industrial PU Block / Polyurethane Elastomer Block / Cast PU Block / Custom PU Block / Polyurethane Wear Block |

| Manufacturing Process | Cast Polyurethane / Solid Polyurethane / Machinable PU Blocks |

| Size Range | Standard: 50–500 mm (length, width, height) Custom sizes available on request |

| Hardness Range | Shore A 60–95 (customizable) |

| Surface Finish | Smooth (standard) Optional: textured, patterned |

| Mechanical Properties | High abrasion resistance, excellent tear and impact strength, low compression set, good dimensional stability |

| Machinability | CNC machining, milling, turning, drilling |

| Applications | Rollers, spacers, bushings, wear pads, protective components, industrial OEM parts |

| Customization / OEM | Cut-to-size, cut-to-shape, custom dimensions, batch production support based on drawings or samples |

| Operating Temperature | –30 °C to +80 °C (special grades available) |

| Colors Available | Natural, Black, Red, Yellow, Custom colors |

Related Products

Custom Polyurethane Block – RFQ Process

To receive a quote, provide:

- Dimensions (length × width × height) or drawing;

- Hardness (Shore A);

- Application type (roller, wear part, spacer, bushing);

- Quantity and production type (prototype or batch);

Our engineers will recommend the optimal block type (solid, cast, or elastomer) and provide a fast, accurate quote to ensure your components meet wear, load, and dimensional requirements.

Custom dimensions up to 500 mm per side; hardness Shore A 60–95.

Yes. Blocks are CNC- and manually-machinable for rollers, bushings, spacers, and wear parts.

Cast blocks suit thick, heavy-duty applications; solid PU blocks are standard industrial stock for general fabrication.

Yes. We support OEM and batch production based on drawings or samples, ensuring consistent material performance.

Yes. These PU blocks provide high wear and impact resistance, outperforming conventional rubber or plastic in industrial applications.