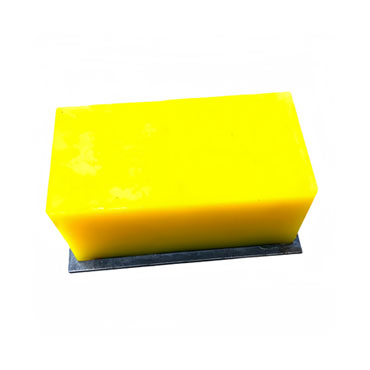

Polyurethane Buffer

Polyurethane buffers are crucial for effective shock absorption and vibration damping in high-impact environments. Made from premium polyurethane materials, our buffers outperform traditional rubber or plastic alternatives by offering superior durability and resistance to harsh industrial conditions. This ensures enhanced protection and extended lifespan for your equipment.

We also provide customization options to ensure our PU buffers perfectly meet the specific needs of your operation, delivering optimal performance for your unique requirements.

High-Performance Vibration Control and Impact Absorption PU Buffer

Why Choose Polyurethane Buffers Over Rubber or Plastic?

- Superior Durability: Unlike traditional rubber, plastic, or metal buffers, polyurethane buffers offer exceptional durability and performance under stress, high temperatures, and heavy loads. They resist wear and tear even in the most demanding environments.

- Vibration & Noise Reduction: PU buffers are designed to absorb vibrations and reduce noise effectively. From automotive applications to machinery and conveyor systems, they minimize vibration-induced damage, enhancing overall system performance.

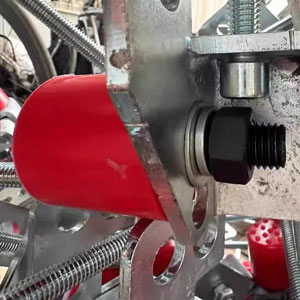

- Impact Protection: Whether used as polyurethane shock absorbers in industrial machinery or urethane bumpers in automotive systems, our buffers offer superior impact protection, safeguarding sensitive components and ensuring smoother operations.

- Custom Solutions: We offer custom polyurethane buffers in various designs—round, flat, square, and custom profiles—tailored to your exact specifications for size, hardness, and performance.

Applications & Industries of Polyurethane Buffer

- 1. Automotive & Machinery: In automotive and mechanical systems, urethane buffers and polyurethane shock absorbers reduce engine and transmission vibrations, ensuring smoother performance and less wear on key components. Our polyurethane mounts and engine mounts provide superior impact resistance for enhanced durability.

- 2. Heavy Equipment & Construction: For cranes, excavators, and other heavy-duty machinery, our polyurethane impact buffers, suspension buffers, and overhead crane buffers offer reliable protection against shocks and vibrations, ensuring efficient operation and reducing the risk of damage.

- 3. Material Handling & Conveyor Systems: In industrial environments, polyurethane vibration buffers and PU vibration dampers are essential for reducing vibrations in conveyor belts, minimizing wear, and ensuring smooth material handling. These buffers help protect machinery and improve overall productivity by preventing excessive vibration damage.

- 4. Elevator Systems: Our polyurethane buffers for elevators and urethane elevator buffers provide excellent shock absorption, protecting elevator components and ensuring a smooth, quiet ride for passengers while extending the lifespan of the system.

Custom Shock-absorbing Parts- Polyurethane Buffer by Application

- Product Specifications

- Gallery

Polyurethane Elastomer Buffers Vs. Microcellular Polyurethane Foam Buffers

| Feature | Polyurethane Elastomer Buffers | Microcellular Polyurethane Foam Buffers |

| Material Composition | Solid polyurethane elastomers | Microcellular polyurethane foam (closed-cell structure) |

| Hardness Range | 60-95 Shore A | 30-60 Shore A |

| Density | 1.12 - 1.25 g/cm³ | 0.2 - 0.6 g/cm³ |

| Weight | Denser, heavier material | Lighter material, compressible foam |

| Temperature Resistance Range | –40°C to +80°C in continuous use, with short-term resistance up to around +120°C. | –30°C to +70°C, with short-term peaks up to +100°C. They are often used where cushioning, compression, and lightweight properties are required |

| Resilience to Impact | High impact resistance, ideal for heavy-duty, high-energy applications | Moderate impact resistance, suitable for lighter-duty applications |

| Compressibility | <30% | >80% |

| Compression Resistance | High, retains shape under heavy load | Lower, softer and more compressible under load |

| Cushioning/damping/energy absorption performance | Moderate energy absorption, slightly resilience for high-energy impactst | Excellent energy absorption, Better resilience for high-impact shocks |

| Flexibility | Medium to high flexibility depending on hardness | High flexibility, softer and more flexible material |

| Durability | Very durable, long lifespan, abrasion-resistant | Less durable, generally suitable for non-heavy-duty applications |

| Application | Crane buffers, elevator buffers, heavy machinery | Shock absorption in lighter machinery, cushioning in automotive, industrial uses |

| Customization | Custom hardness and formulation available for specification application | Limited customization, typically standardized foams, not as flexible |

| Cost | Higher cost, suitable for demanding applications | Lower cost, economical for lighter applications |

Our Product Range

- Polyurethane Vibration Buffers / PU Vibration Dampers:Designed for noise reduction and vibration control, these buffers are essential for machinery, conveyors, and automotive systems.

- Polyurethane Impact Buffers / Urethane Impact Buffers:Offering superior protection against shock and impact, these buffers are used in machinery, automotive, and industrial applications to protect sensitive components from damage.

- Polyurethane Suspension Buffers:Ideal for automotive systems, these buffers improve the comfort and longevity of suspension systems, reducing vibrations and shocks.

- Polyurethane Shock Absorbers / Urethane Shock Absorbers:Engineered for high-performance shock absorption, these buffers ensure smooth operations even under heavy impact, ideal for mechanical and automotive applications.

- Polyurethane End Stops / Polyurethane Bumper Stops:Used in conveyor systems and heavy machinery to stop components from moving beyond designated limits, providing effective shock absorption and impact protection.

- Custom Polyurethane Buffers:We offer fully customized solutions to meet your specific performance, hardness, and size requirements, ensuring optimal results for your unique application.

Why Choose Us?

- High-Quality Materials:Our polyurethane buffers are made from high-grade materials, ensuring superior performance in harsh environments. Choose from microcellular polyurethane, high-density polyurethane elastomers, or foam-based options for different applications.

- Customization:We specialize in custom polyurethane buffers, offering tailored solutions for every industry, from automotive to industrial machinery. If your project requires specific dimensions, hardness, or resilience, we can create the ideal product.

- Reliable Performance:Our PU buffers are designed to handle heavy-duty performance demands, from absorbing high-impact forces to isolating vibrations. We aim to deliver a product that provides longevity and reliability.

Related Products

Request a Quote for Polyurethane Buffer

Looking for durable and reliable Polyurethane Buffers / PU Buffers for your application? We offer customized pu buffer designed to absorb shock, dampen vibration, and provide long-lasting performance in harsh environments.

Simply share your specifications—such as dimensions, hardness, quantity, load requirements, or operating conditions—and we’ll deliver a tailored quotation to match your needs quickly and efficiently.

Yes, we offer customization options for polyurethane buffers to meet the unique requirements of your operation. Whether you need specific sizes, shapes, or hardness, we can tailor the buffers to suit your needs for optimal performance.

Microcellular polyurethane buffers are made from a foam-like material, providing higher compressibility and lightweight properties. They are ideal for applications requiring greater cushioning, while standard polyurethane buffers offer more rigidity and durability for heavy-duty applications.

Selecting the right buffer depends on factors such as load-bearing capacity, hardness, size, and environmental conditions. Our team can help guide you in choosing the perfect polyurethane buffer based on your specific needs and operating conditions.

Yes, polyurethane buffers offer excellent resistance to chemicals, oils, solvents, and UV exposure. This makes them ideal for use in harsh environments such as manufacturing facilities, outdoor machinery, and automotive systems.

- Polyurethane Elastomer Buffers: Typically withstand –40°C to +80°C in continuous use, with short-term resistance up to around +120°C. These are commonly used in crane buffers, elevator buffers, and heavy-duty machinery.

- Microcellular Polyurethane Foam Buffers: Generally suitable for –30°C to +70°C, with short-term peaks up to +100°C. They are often used where cushioning, compression, and lightweight properties are required, such as suspension bump stops or isolators.

- Both materials offer excellent durability and wear resistance, but elastomer buffers are better suited for higher-temperature and heavy-load applications, while microcellular foam buffers are preferred when lightweight cushioning and energy absorption are the priority.

Polyurethane buffers (PU buffers) are designed to perform reliably across a wide temperature range, but the exact resistance depends on the material type: