Polyurethane Conveyor Rollers

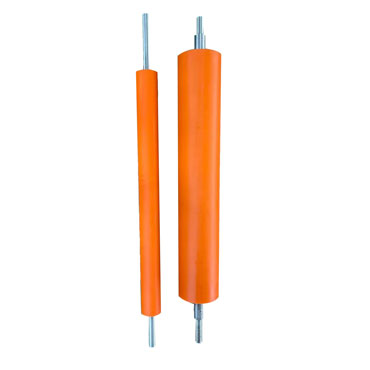

Polyurethane conveyor rollers are essential components in various industrial conveying systems. It is composed of a cylindrical core made of steel or aluminum and molded polyurethane. The polyurethane layer forms the outer surface of the roller, which comes into contact with the conveyor belt and the conveyed product. We can custom polyurethane conveyor rollers to fit your equipment and application.

Polyurethane Conveyor Roller Suppliers

Polyurethane Conveyor Rollers Application

- 1. Manufacturing Industries: In factories that produce goods like automotive parts, electronics, or consumer products, polyurethane conveyor rollers are used to transport components along the assembly line. Their high durability and smooth operation help maintain the efficiency of the production process.

- 2. Logistics and Warehousing: In warehouses and distribution centers, these rollers are used in conveyor systems for sorting, loading, and unloading goods. Their ability to handle different types of packages and products, along with their long - lasting nature, makes them a preferred choice for keeping the flow of goods smooth.

- 3. Food and Beverage Industry: Polyurethane can be formulated to meet food - contact safety standards. As a result, conveyor rollers made of this material are used in food processing and packaging facilities to transport food products, ensuring hygiene and safety.

Properties of Polyurethane Conveyor Rollers

- High Abrasion Resistance

- Good Elasticity

- High Impact Resistance

- Chemical Resistance

Custom Polyurethane Conveyor Rollers Manufacturer

- Product Specifications

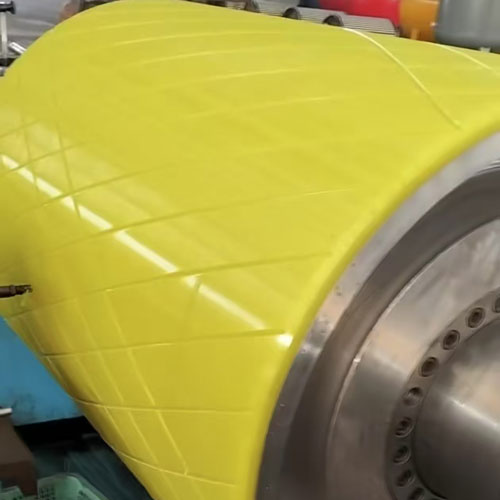

- Gallery

Dimensions of polyurethane conveyor rollers

Conveyor rollers can come in a wide range of diameters, typically starting from as small as 25 mm (1 inch) for some light - duty applications, and going up to 200 mm (8 inches) or even larger for heavy - duty industrial uses. For example, in a small - scale electronics assembly line, 50 - 75 mm diameter rollers might be used, while in a large - scale automotive manufacturing conveyor system, rollers with diameters of 150 - 200 mm could be employed.

Length of PU conveyor Rollers

Roller lengths vary according to the width of the conveyor belt and the application requirements. They can range from a few centimeters to several meters. Common lengths for industrial conveyor rollers are between 500 mm (19.7 inches) and 2000 mm (78.7 inches). In a narrow - width conveyor used for sorting small parts, a roller length of 600 - 800 mm might be sufficient, while in a wide - belt conveyor for transporting large items like sheets of plywood, rollers could be 1800 - 2000 mm long.

Polyurethane Material - Related hardness and density

Different grades of polyurethane are used based on the specific requirements of the application. For example, for high - wear environments, a grade with high abrasion resistance and hardness might be selected. Shore hardness of the polyurethane can range from around 60A to 95A. A softer polyurethane (e.g., 60 - 70A) might be used in applications where a more cushioned surface is needed to handle delicate products, while a harder grade (e.g., 90 - 95A) is suitable for heavy - duty and high - friction applications.

Typical densities of polyurethane range from 1.1 - 1.3 g/cm³. Higher - density polyurethanes generally offer greater strength and durability.

Steel Conveyor Roller Core Material

The core of the conveyor roller is often made of steel or aluminum. Steel cores provide high strength and are suitable for heavy - load applications. Aluminum cores, on the other hand, are lighter in weight, which can be beneficial in some applications where weight reduction is important, such as in conveyor systems with frequent movement or in applications where energy efficiency is a concern.

Conveyor Rollers Performance Specifications

1). Load Capacity - This specification indicates the maximum weight that the roller can support while operating properly. Load capacities can range from a few kilograms for light - duty rollers used in small - scale production lines to several tons for heavy - duty rollers in mining, steel, or automotive manufacturing conveyor systems. For example, a light - duty roller might have a load capacity of 50 - 100 kg, while a heavy - duty roller could handle 5000 - 10000 kg or more.

2). Rotational Speed - Conveyor rollers are designed to operate at specific rotational speeds. The maximum rotational speed is determined by factors such as the roller's construction, the quality of its bearings, and the material properties. Industrial conveyor rollers can typically operate at speeds ranging from a few revolutions per minute (RPM) for slow - moving conveyors in some processing applications to several thousand RPM for high - speed sorting or packaging conveyors.

3).Torsional Rigidity - This measures the roller's ability to resist twisting forces. High torsional rigidity is important to ensure that the roller maintains its shape and alignment during operation, especially when subjected to uneven loads or forces that can cause twisting. The torsional rigidity of a roller depends on its core material, diameter, and wall thickness.

4). Surface Finish and Coating - The surface of the polyurethane conveyor roller can have different finishes. A smooth surface finish is common for most applications as it reduces friction with the conveyor belt and helps in the smooth movement of products. The surface roughness can be specified in terms of Ra (arithmetical mean deviation of the surface profile), with values typically ranging from 0.5 - 2 μm for a smooth - running roller.

5). Anti - static polyurethane Coating- In some industries, such as electronics manufacturing or food processing, an anti - static coating may be applied to the polyurethane roller. This helps prevent the build - up of static electricity, which can attract dust or cause damage to sensitive electronic components. The anti - static properties can be specified in terms of surface resistivity, typically in the range of 10⁶ - 10¹² ohms per square.

PU Conveyor rollers with Bearing

1). Bearing Type - Conveyor rollers can be equipped with different types of bearings, such as ball bearings or roller bearings. Ball bearings are often used for light - to medium - load applications and offer smooth rotation at relatively high speeds. Roller bearings, on the other hand, can handle heavier loads and are more suitable for applications where shock and vibration resistance are required.

2). Bearing Size and Clearance - The size of the bearing is selected based on the roller's dimensions and load capacity. The clearance within the bearing is also an important specification. Proper bearing clearance ensures smooth rotation and reduces the risk of overheating or premature wear. Clearance values are typically specified in thousandths of an inch or millimeters.

Polyester polyol/TDI series prepolymer

| Model | D3136 | D3145 | D3160 |

| NCO content / % | 3.6±0.1 | 4.5±0.2 | 6.0±0.2 |

| State of matter At 20℃ | White waxy solid | White waxy solid | White waxy solid |

| MOCA 100g prepolymer dosage /g | 10.5 | 13.2 | 17.2 |

| Viscosity(85℃)/ mpa * s | 1800 | 1200 | 900 |

| Mixing Temperature /℃(prepolymer/MOCA) | 85/120 | 80/120 | 75/120 |

| Gel time /min | 9 | 7.5 | 5 |

| Post vulcanization time (100℃)/h | 10 | 10 | 10 |

| Hardness ( shore A) | 85±1 | 91±1 | 96A±1 (54D) |

| 100% constant tensile stress /MPa | 4.2 | 6.7 | 11.5 |

| 300% constant tensile stress /MPa | 8.3 | 12.5 | 21.3 |

| Tensile strength /MPa | 48 | 52 | 55 |

| Elongation at break / % | 670 | 610 | 530 |

| Tear strength (right angle) /(KN/m) | 75 | 95 | 124 |

| Tear strength (pants type) /(KN/m) | 34 | 42 | 49 |

| Rebound /% | 39 | 32 | 33 |

| Density (25℃)/(g/cm) | 1.26 | 1.27 | 1.29 |

| wearing out by friction mm³ | 40 | 48 | 57 |

Polyether polyols PTMG series prepolymer

| Model | D2135 | D2142 | D3160 |

| NCO content / % | 35±0.1 | 4.2±0.2 | 6.2±0.2 |

| State of matter At 20℃ | White waxy solid | White waxy solid | White waxy solid |

| MOCA 100g prepolymer dosage /g | 10 | 12.1 | 18 |

| Viscosity(85℃)/ mpa * s | 1200 | 750 | 480 |

| Mixing Temperature /℃(prepolymer/MOCA) | 85/120 | 85/120 | 80/120 |

| Gel time /min | 11 | 10 | 6 |

| Post vulcanization time (100℃)/h | 10 | 10 | 10 |

| Hardness ( shore A) | 85±2 | 90±1 | 95A±1 (49D±2) |

| 100% constant tensile stress /MPa | 5.4 | 7.5 | 12.8 |

| 300% constant tensile stress /MPa | 9.6 | 14.1 | 36.3 |

| Tensile strength /MPa | 27 | 33 | 48 |

| Elongation at break / % | 550 | 500 | 350 |

| Tear strength (right angle) /(KN/m) | 65 | 78 | 95 |

| Tear strength (pants type) /(KN/m) | 21 | 28 | 33 |

| Rebound /% | 61 | 54 | 47 |

| Density (25℃)/(g/cm) | 1.07 | 1.09 | 1.13 |

MDI series prepolymer

| Model | D3560M |

| NCO content / % | 6.0 |

| Viscosity(80℃)/ mpa * s | 1780 |

| D3560M : D3575-C | 100:6.1 |

| Gel time /min | 8-11 |

| Post vulcanization time (100℃)/h | 48 |

| Hardness ( shore A) | 83±3 |

| Tensile strength /MPa | 46 |

| Elongation at break / % | 580 |

| Tear strength (right angle) /(KN/m) | 82 |

| Rebound /% | 38 |

| Density (25℃)/(g/cm) | 1.2 |

Related Products

Custom Polyurethane Conveyor Roller Manufacturers

We are a manufacturer of urethane molding and urethane products, and we customize a wide range of industrial urethane conveyor rollers for automotive manufacturers, electronics manufacturers, food and beverage processors, logistics centers, warehousing and distribution companies, and conveyor system engineering contractors.

Whether you have light or heavy industrial needs, we can customize polyurethane conveyor rollers in a variety of sizes and hardnesses to fit your application or design drawings. Our polyurethane conveyor rollers reduce wear and tear between the conveyor belt and the rollers, lowering maintenance costs and ensuring stable operation of the conveyor system.

Yes, we specialize in providing customized solutions. We can manufacture Polyurethane Conveyor Rollers in various sizes, diameters, and lengths to meet your specific needs. Just provide us with the detailed dimensions.

The lifespan depends on several factors such as the operating environment, load conditions, and maintenance. Under normal operating conditions, our rollers can last for several years. Regular maintenance and proper usage can further extend their lifespan.

Yes, our Polyurethane Conveyor Rollers are designed to perform well in high - speed conveyor systems. They have excellent dynamic balance and can handle the high rotational speeds without compromising on performance.

Our rollers are made of polyurethane materials with good chemical resistance. They can withstand certain corrosive substances. However, for extremely corrosive environments, we can provide special coatings or customized materials to enhance corrosion resistance.

The lead time varies depending on the complexity of the customization and the order quantity. Generally, it takes [15] days to [20] days. We will provide you with a specific lead time once we receive your detailed requirements.