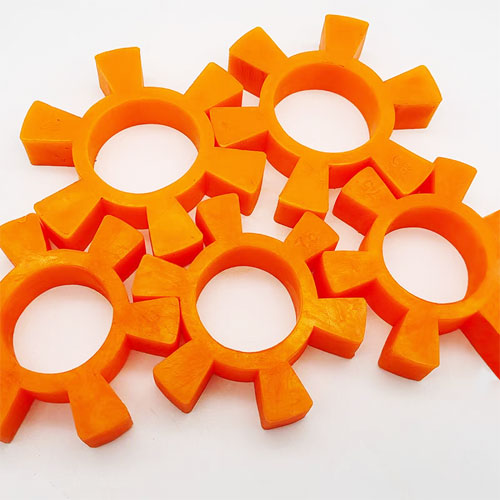

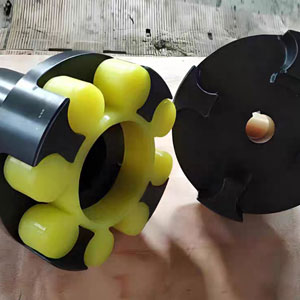

Polyurethane Couplings

Polyurethane couplings—also known as urethane couplings or PU couplings—provide flexible, vibration-damping torque transmission for industrial machinery. Durable, abrasion-resistant, and chemically stable, they absorb shocks, compensate for misalignment, and extend equipment life.

Available in custom sizes, hardness levels, and designs, these couplings fit OEM machinery or standard PU spider replacements. They improve operational efficiency, reduce maintenance, and ensure reliable performance in demanding applications.

OEM & Custom-Engineered Polyurethane Couplings

Why Choose Our Polyurethane Couplings?

- Shock & vibration reduction-Polyurethane’s elasticity dampens impact and torsional vibration better than metal or rigid couplings.

- Durability under load-Excellent wear and oil resistance extends service life in harsh environments.

- Maintenance cost reduction-Long lifespan reduces replacement frequency and machine downtime.

- Compatibility & customization-Can be tailored in hardness, bore, keyway, and hub design to fit specific torque and alignment needs.

- Operational smoothness-Provides consistent torque transmission with minimal backlash or noise.

Application of Polyurethane Couplings

- Industrial automation systems;

- Conveyor and power transmission drives;

- CNC machinery and precision equipment;

- Hydraulic and pneumatic pumps;

- OEM machinery and maintenance replacement parts.

Maintenance & Replacement Coupling Damping Pad for Shaft Alignment

- Product Specifications

- Gallery

| Specification | Details |

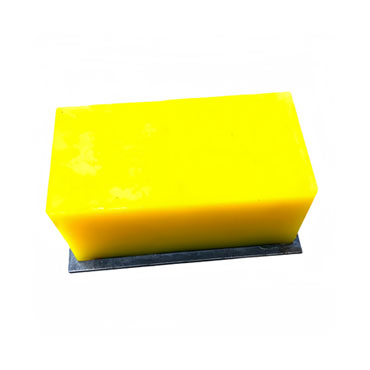

| Material | High-performance TPU polyurethane elastomer; Shore hardness 90A–98A; oil, chemical, abrasion-resistant; optional UV/heat/solvent resistance |

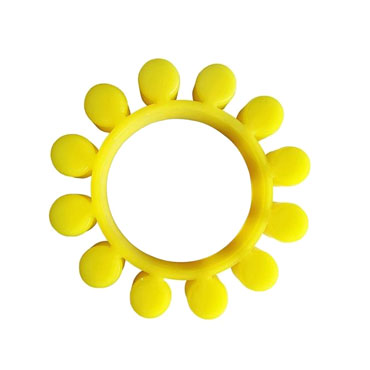

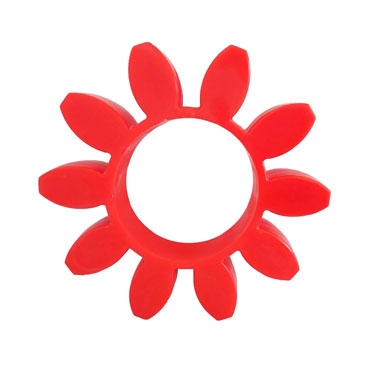

| Coupling Types | Jaw Couplings, PU Spider Couplings, Flexible Shaft Couplings, Custom Polyurethane Couplings, Replacement Spider/Insert Elements |

| Torque Capacity | Typically 5–500 Nm (application-dependent) |

| Speed Range | Up to 3000 RPM (depending on design and hub material) |

| Misalignment Tolerance | Accommodates angular, parallel, and axial misalignment |

| Temperature Range | Standard: -30°C to 80°C; high-temperature variants available |

| Design Features | Vibration/shock absorption; noise reduction; replaceable inserts; high dimensional stability |

| Applications | Industrial machinery, conveyors, pumps, CNC machines, OEM equipment, maintenance/retrofit |

| Customization Options | Shore hardness, bore diameter, keyway configuration, hub material (steel/aluminum), coupling length/geometry, pre-assembled or separate components |

Key Features and Benefits of Polyurethane Couplings

- High elasticity and vibration damping to protect shafts and gears;

- Excellent wear, abrasion, and chemical resistance for long-term durability;

- Customizable hardness, bore size, and geometry for OEM machinery;

- Easy installation and replacement, reducing maintenance downtime;

- Suitable for high-speed, high-torque, and misalignment-prone applications.

Related Products

Polyurethane Couplings to Optimize Your Equipment Performance

Lisen provides high-performance polyurethane, rubber, and nylon couplings designed for precise torque transmission, vibration damping, and shock absorption. Crafted from premium TPU, rubber, or nylon materials, these couplings offer superior tensile strength, elasticity, wear resistance, and fatigue durability, making them ideal for industrial metal shaft applications.

Improve your machinery efficiency and reduce maintenance with polyurethane couplings. Whether you need custom designs, replacement PU spider couplings, or standard industrial couplings, our solutions ensure reliable, long-lasting performance in demanding applications.

Polyurethane couplings are mechanical components designed to connect two shafts, transmitting torque while compensating for misalignment. They utilize the unique properties of polyurethane to absorb shocks, reduce vibrations, and provide a flexible connection between shafts.

Polyurethane couplings offer superior durability, high elasticity, and excellent resistance to abrasion and chemicals. They effectively dampen vibrations and shocks, leading to reduced wear and extended service life of connected equipment.

Compared to rubber, polyurethane couplings provide higher load-bearing capacity and better resistance to wear and chemicals. Unlike plastic, they offer greater flexibility and can withstand harsher operating conditions, making them suitable for demanding industrial applications.

Polyurethane couplings are widely used in various industries, including automotive, manufacturing, robotics, and material handling. Their versatility makes them ideal for applications requiring reliable torque transmission and resistance to harsh conditions.

Choosing the appropriate polyurethane coupling involves considering factors such as torque requirements, shaft misalignment, environmental conditions, and space constraints. Our team can assist you in selecting the ideal coupling by evaluating your specific application needs and providing tailored recommendations.