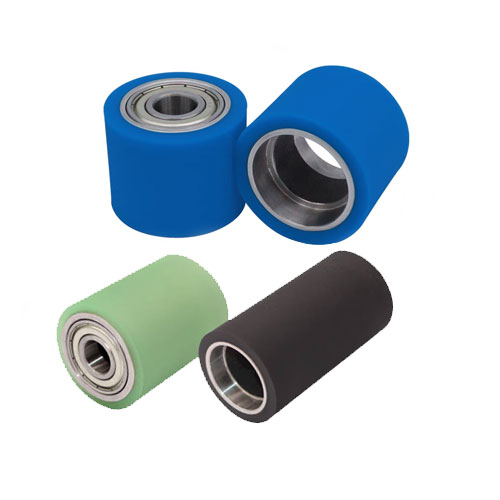

Polyurethane Drive Wheels

Polyurethane Drive Wheels designed to transmit power or motion in drive systems (robotics, conveyors, machinery, etc.).

Looking for a reliable drive wheel that doesn’t wear out under pressure? Our polyurethane drive wheels are engineered for long service life, exceptional load capacity, and excellent traction. Whether you need custom bores, keyways, or complete OEM drive assemblies, we manufacture to your exact specs—reducing downtime.

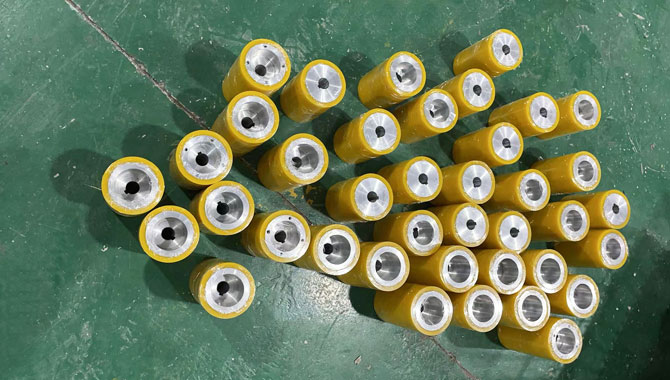

Custom Molded Polyurethane Drive Wheels

Why Choose Our Polyurethane Drive Wheels?

- Superior Abrasion Resistance- Outlasts rubber, plastic, or metal wheels.

- High Load Capacity- Supports heavy-duty applications without deformation.

- Custom Molded Options- Designed to your specifications (hardness, bore, keyway).

- Low Noise & Vibration- Reduces equipment noise and extends bearing life.

- Seamless Integration- Options for bushings, bearings, shafts, and hubs.

Applications of Polyurethane Drive Wheels

- Automated guided vehicles (AGVs)

- Packaging machinery

- Conveyor drives

- Printing presses

- Robotic systems

- Material handling equipment

Customize Polyurethane Idler Wheels

- Product Specifications

- Gallery

| Specification | Details of Polyurethane Idler Wheels | Details of Polyurethane Drive Wheels |

| Material | Molded polyurethane with steel/plastic/aluminum core | High-performance cast polyurethane (Shore A 70–95 or Shore D options) |

| Diameter Range | 25 mm – 400 mm (larger sizes on request) | 50 mm – 500 mm (larger sizes on request) |

| Tread Width | 25mm – 100 mm | 25mm – 150mm |

| Bore Type | With or without bearing; straight bore or custom bore available | Straight bore, keyed bore, D-bore, taper-lock, hex, or custom |

| Keyway/Bushing Options | Custom-machined keyways, set screws, and bushing-ready configurations | |

| Bearing Options | Press-fit or integrated sealed bearings (ZZ or 2RS) | Sealed ball bearings or roller bearings available for hybrid drive/idler use |

| Load Capacity | Light-duty to 1,000 kg, depending on size | Up to 2,000 kg (depending on diameter and design) |

| Hardness (Durometer) | Shore A 80–95 (custom formulations available) | Shore A 70–95 or Shore D 50–75 |

| Color Options | Natural, red, orange, blue, black,Yellow | Natural, red, orange, blue, black,Yellow |

| Temperature Resistance | -40°C to +80°C (up to 120°C intermittent) | -40°C to +95°C (up to 120°C intermittent) |

| Noise/Vibration | Low-noise and vibration-dampening performance | Low-noise and vibration-dampening performance |

| Applications | Conveyor support, guide rollers, track rollers, tensioners | Conveyor support, guide rollers, track rollers, tensioners |

| Customization | Chamfered edges, crowned profile, flanged, anti-static PU | Groove profile, tread pattern, hub coating, anti-static, colored PU |

Polyurethane wheels categories we made

| Wheel Type | Core material | Feature | Application | Available Customization |

| PU Drive Wheels | PU with Steel /aluminum | High Load, standard bore/keyway | Conveyor Systems, Factory | Size ,hardness |

| Custom Molded PU drive Wheels | PU+ Custom metal /aluminum | Fully custom hardness | OEM machinery | Yes |

| PU Coated Drive Rollers & Idler Wheels | Steel/Aluminum core +PU | Smooth Surface, No-slip Coating | Automation, Conveyors | Yes |

| High-Traction /High Speed PU Drive Wheels | Lightweight Aluminum +PU | Quiet,High-Friction,Low Noise | Robotics, AGVs | Tread,hardness, core type |

| PU Drive Wheels with Bearings | PU with Integrated Bearings | Smooth, Low-Friction Rotation | Precision Systems | Bearing type, Tread pattern |

Related Products

Polyurethane Drive Wheels Manufacturer and Supplier

We manufacture a wide range of high-performance polyurethane drive wheels and urethane idler wheels designed for industrial machinery, conveyors, robotics, and automation equipment. Choose from keyed, bored, or bearing-integrated wheels to meet your needs.

Drive wheels are mounted to turn with a powered shaft—using keyways, bushings, or bonding—to apply traction or propel material. Idler wheels rotate freely (often using bearings) and serve as guides or supports. We manufacture both to withstand mechanical stress and deliver smooth, reliable operation.

Select based on load, speed, and airflow:

- Softer (~70 A) for smoother grip at low speeds

- Medium (~80 A) for general industrial use

- Harder (Shore D) for high-load or high-speed environments

- We guide you through selecting the ideal durometer for optimal performance.

Compared to rubber and metal, polyurethane drive wheels provide:

- Higher abrasion and chemical resistance

- Greater load capacity

- Reduced noise and vibration

- Better floor protection

- They offer superior lifecycle value in demanding applications.

Yes, we can balance wheels to specific RPMs, manufacture to ASTM/ISO standards, and supply special urethane formulations for water or chemical exposure. We also offer color and core customization for precise application needs.

- Resistant to abrasion, oils, and chemicals,

- Quieter than metal or rubber, and kinder to floors,

- Customizable material hardness and bonding methods ensure longevity.