Polyurethane Extrusion

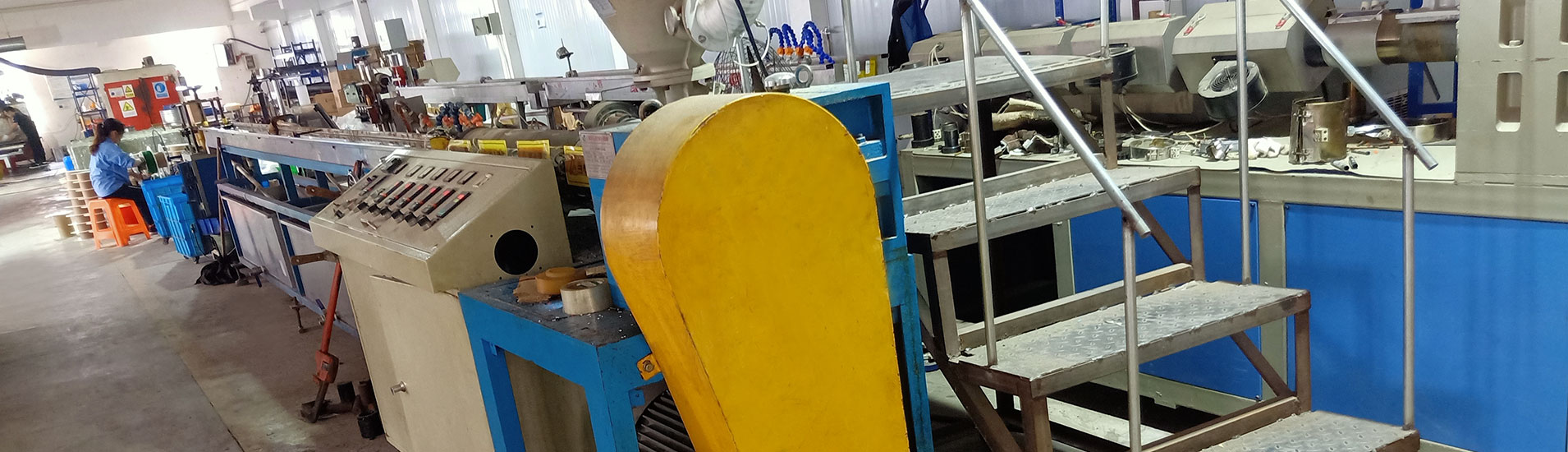

Polyurethane extrusion is a manufacturing process in which we heat urethane material and force it through a shaped die to create continuous profiles or tubes. After extrusion, we cool, cut, and finish the material to meet precise specifications.

Key benefits include:

- High precision and dimensional consistency.

- Long continuous parts with uniform cross-section.

- Customizable properties such as hardness, flexibility, and abrasion resistance.

- Durable performance in wear, impact, and chemical exposure.

We specialize in polyurethane extrusion and provide custom PU extrusion solutions for industries requiring durable, high-performance components. Our advanced extrusion technology produces parts with consistent dimensions, smooth surfaces, and excellent mechanical properties.

Whether you need long continuous profiles, custom shapes, or specialized urethane formulations, we deliver tailored solutions that meet functional and aesthetic requirements. Our services serve industries including industrial machinery, automotive, mining, material handling, construction, and consumer products.

Our PU Extrusion Capabilities

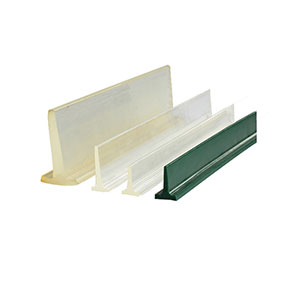

- Custom Profile Extrusion – Tubes, rods, sheets, seals, gaskets, and complex shapes.

- Material Flexibility – Hardness options from soft elastomers to rigid polyurethane.

- Continuous Lengths – Long or short extrusions to fit specific applications.

- Color & Additives – Custom colors, UV resistance, flame-retardant, FDA-compliant grades.

- Secondary Processing – Cutting, slitting, machining, or surface finishing.

- Low-Volume & High-Volume Production – From prototypes to mass production runs.

Advantages of Extruded Polyurethane

- Superior wear and abrasion resistance compared to rubber or plastics.

- High tensile strength and flexibility, suitable for dynamic applications.

- Consistent cross-section for mechanical and sealing applications.

- Versatile shapes and sizes, including custom designs and complex profiles.

- Chemical and environmental resistance, ideal for harsh industrial settings.

Quality Control of Custom Extruded Polyurethane Profiles

We ensure that every extruded polyurethane profiles meets strict quality standards:- Dimensional checks to verify tolerances.

- Hardness and mechanical testing to ensure performance.

- Material consistency verification for color, flexibility, and formulation.

- Production monitoring to maintain consistent extrusion temperature, pressure, and cooling.

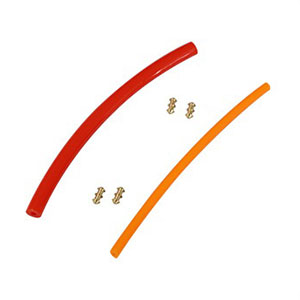

Extruded Polyurethane Profiles Examples

Application scenarios of PU Extrusion

Why Choose Us?

As a trusted polyurethane extrusion manufacturer, we combine:

- Advanced PU extrusion technology;

- Customizable material formulations;

- End-to-end support from design to production;

- On-time delivery and competitive pricing;

We provide flexible, reliable, and high-performance polyurethane extrusion solutions tailored to your application needs.

Extruded polyurethane offers high wear and abrasion resistance, flexibility, tensile strength, and chemical resistance. It provides consistent dimensions, smooth surfaces, and long-lasting performance in demanding applications.

We produce pu belts,seals, gaskets, rollers sleeve, rods, tubes, protective edging, wear strips, and custom profiles for a variety of industrial and consumer applications.

Common applications include automotive, industrial machinery, mining, material handling, construction, food & packaging, and consumer products.

Yes. We can adjust durometer (hardness), color, flexibility, UV resistance, FDA compliance, and flame-retardant properties to meet your specific application needs.

Extrusion is best for continuous profiles with uniform cross-sections, whereas casting is more suited for low- to medium-volume custom parts, and injection molding is ideal for high-volume, complex shapes with tight tolerances.

Submit your drawings, CAD files, or specifications, and we’ll provide a customized quote quickly.