Polyurethane Flat Belts

Polyurethane Flat Belts (also called Urethane Flat Belts) are used for power transmission and material movement in industrial machinery. Made from polyurethane (PU) or urethane, these PU flat belts offer strong mechanical power transfer. Their flat design allows for a broad contact surface with pulleys or rollers, ensuring stable, efficient operation.

Urethane Flat Belts for Industrial Applications

Key Features & Benefits of Polyurethane Flat Belts

- Superior Durability

- Flexible & Reliable

- Cost-Effective

- Customizable

Applications of PU Flat Belts

- Conveyor Systems

- Power Transmission

- Material Handling

- Packaging and Food Processing

- Bandsaw Machine for Woodworking

Urethane Flat Belt Tires for Bandsaws in Woodworking Process

- Product Specifications

- Gallery

| Specification | Details |

| Material | Polyurethane (Urethane), known for abrasion resistance, flexibility, chemical resistance, and tensile strength. |

| Width | Typically ranges from 10 mm to 600 mm or more, depending on customer requirements. Custom widths available. |

| Thickness | Available in various thicknesses from 2 mm to 20 mm or more, based on application and load requirements. |

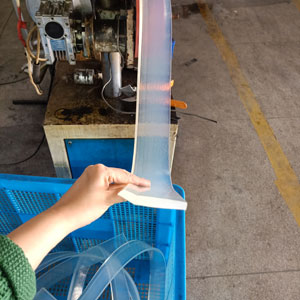

| Length | Can be supplied in custom lengths or continuous loops, with the option for cut-to-size or endless loops. |

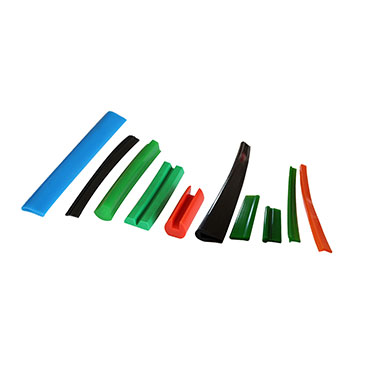

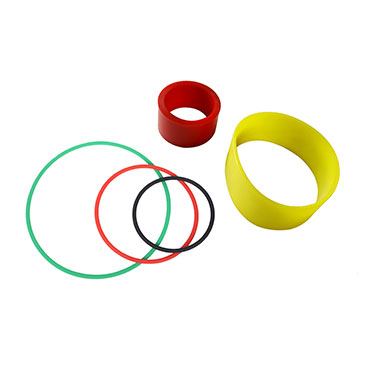

| Shape | Primarily flat, but can also be custom profiles for specific applications. Flat belts are the most common. |

| Hardness | Shore A 70 to 98, depending on the application’s requirements for flexibility and durability. |

| Tensile Strength | Typically ranges from 35 MPa to 80 MPa, ensuring high load-bearing capacity for industrial applications. |

| Elongation at Break | Ranges from 200% to 400%, depending on the thickness and formulation of the belt. |

| Operating Temperature | -40°C to 80°C (-40°F to 176°F), making them suitable for both low and high temperature environments. |

| Chemical Resistance | Resistant to oils, greases, water, and various chemicals, making them suitable for demanding industrial environments. |

| UV and Weather Resistance | Resistant to UV light, ozone, and weathering, ensuring longevity when used in outdoor or harsh environments. |

| Color | Typically clear, yellow, or black, but custom colors are available upon request. |

| Reinforcement | Available with reinforcement options such as steel wire, Kevlar, or fiberglass for added strength in heavy-duty applications. |

| Applications | Used in conveyors, material handling systems, power transmission, automated machinery, and robotic systems. |

| Compliance | Conforms to ISO 9001 standards and can meet specific customer requirements (e.g., FDA compliance for food industry applications). |

Related Products

Why Choose Polyurethane Flat Belts

Our Polyurethane Flat Belts offer exceptional strength, abrasion resistance, and long-lasting durability. Perfect for power transmission, material handling, and conveying systems, these belts are engineered to perform in even the most demanding industrial environments. Whether you need belts for automated systems, packaging lines, or manufacturing processes, we have a solution that meets your requirements.

Polyurethane flat belts offer superior abrasion resistance, chemical resistance, and tensile strength compared to traditional rubber belts. They also perform well in high-torque applications, are more flexible, and offer a longer operational life, reducing maintenance and replacement costs.

To select the right size, consider the belt width, thickness, and length required for your application. Custom sizes are available to fit your specific needs. We also offer flat polyurethane belts with different hardness levels (Shore A 70 to 98) based on load capacity and flexibility.

Yes, we provide customized polyurethane flat belts to meet specific operational needs. You can select from various widths, thicknesses, and hardness. Additionally, we offer custom profiles and the option for reinforced belts for heavy-duty use, including Kevlar, steel wire, or fiberglass reinforcement.

Yes, PU flat belts are highly resistant to oils, greases, and many common industrial chemicals, making them ideal for chemical processing, food processing, and automotive applications. Their chemical resistance helps reduce wear and tear, ensuring a longer lifespan in harsh environments.

Polyurethane flat belts require minimal maintenance. Regular inspection for wear and abrasion is recommended, especially in high-load applications. Keep the belts clean, free of debris, and properly tensioned to ensure smooth operation and longevity.