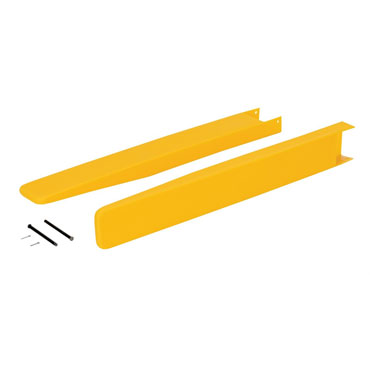

Polyurethane Fork Covers

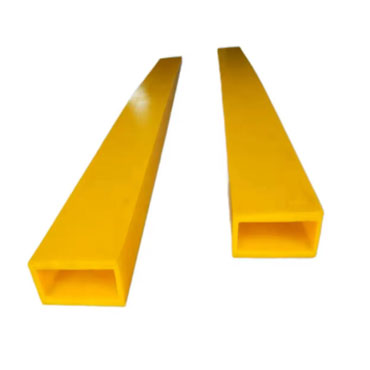

Polyurethane fork covers—also known as forklift fork covers, polyurethane fork protectors, fork protectors forklift—are durable protective sleeves that fit securely over forklift forks. Made from high-strength, non-marking polyurethane, they offer excellent resistance to abrasion, impact, and wear.

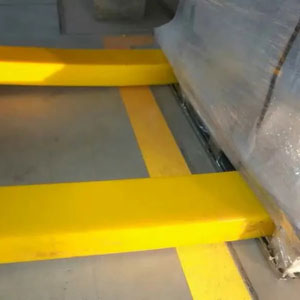

By acting as a barrier between steel forks and sensitive goods, these forklift fork sleeves and blade protectors help prevent scratches, dents, and product damage. They are ideal for handling delicate or high-value items such as food products, electronics, pharmaceuticals, and finished goods.

Customized Wear Resistant Polyurethane Forklift Fork Sleeves Covers

Why use Polyurethane Fork Covers?

- Protects products, pallets, and warehouse floors from forklift damage.

- Extends the life of forklift forks by reducing direct wear and tear.

- Made of abrasion-resistant polyurethane, a non-marking, durable material.

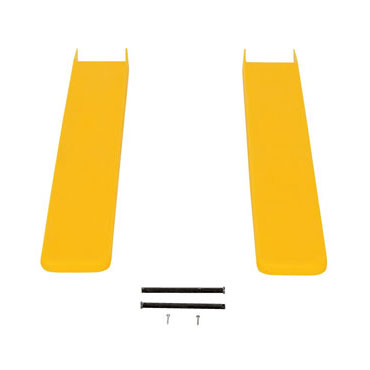

- Quick to install and easy to replace.

- Customizable in hardness, thickness, and dimensions.

Applications of Urethane Forklift Fork Covers

- Warehousing & Logistics – Prevent scratches and dents on packaged goods, pallets, and crates during transport and storage.

- Food & Beverage Industry – Handle packaged foods, bottled goods, and fragile containers safely with non-marking polyurethane covers.

- Pharmaceutical & Medical Supply – Protect sensitive equipment and sterile products from punctures or surface contamination.

- Electronics & Appliances – Avoid costly damage to delicate electronics, appliances, and finished goods during loading and unloading.

- Automotive & Aerospace – Safeguard high-value parts, assemblies, and painted components from chipping or surface scratches.

- Cold Storage & Freezers – Ensure reliable performance in low temperatures where rubber sleeves would harden or crack.

- Retail & Distribution Centers – Provide additional safety when handling high-turnover, customer-ready goods that need to remain in pristine condition.

Custom Urethane & Polyurethane Fork Covers for Forklift Protection

- Product Specifications

- Gallery

Benefits of Polyurethane Fork Covers

- Reduce product damage and warehouse losses;

- Improve workplace safety by cushioning impacts;

- Lightweight and reusable, lowering long-term costs;

- Compatible with most forklift models;

- Custom manufacturing available.

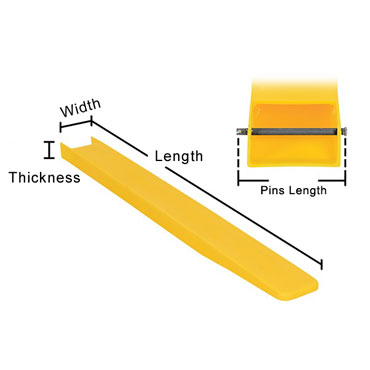

Specification of Polyurethane Fork Covers

| common forklift fork size | ||||||||||

| LxWxT | W | T | L | Forklift | ||||||

| mm | mm | mm | mm | |||||||

| 920x100x30 | 100 | 30 | 920 | 1070 | 1220 | 1370 | 1520 | 1t | ||

| 920x100x35 | 100 | 35 | 920 | 1070 | 1220 | 1370 | 1520 | 1.5t | ||

| 1070x120x40 | 120 | 40 | 1070 | 1220 | 1370 | 1520 | 1670 | 1820 | 1970 | 2t |

| 1070x120x45 | 120 | 45 | 1070 | 1220 | 1370 | 1520 | 1670 | 1820 | 1970 | 2.5t |

| 1070x125x45 | 125 | 45 | 1070 | 1220 | 1370 | 1520 | 1670 | 1820 | 1970 | 3t |

| 1070x125x50 | 125 | 50 | 1070 | 1220 | 1370 | 1520 | 1670 | 1820 | 1970 | 3.5t |

| 1070x125x50 | 125 | 50 | 1070 | 1220 | 1370 | 1520 | 1670 | 1820 | 1970 | 4t |

| 1070x150x50 | 150 | 50 | 1070 | 1220 | 1370 | 1520 | 1670 | 1820 | 1970 | 4.5t |

| 1220x150x50 | 150 | 50 | 1220 | 1370 | 1520 | 1670 | 1820 | 1970 | 2120 | 5t |

| 1220x150x60 | 150 | 60 | 1220 | 1370 | 1520 | 1670 | 1820 | 1970 | 2120 | 6t |

| 1220x150x65 | 150 | 65 | 1220 | 1370 | 1520 | 1670 | 1820 | 1970 | 2120 | 7t |

| 1220x170x70 | 170 | 70 | 1220 | 1370 | 1520 | 1670 | 1820 | 1970 | 2120 | 8t |

| 1220x175x80 | 175 | 80 | 1220 | 1370 | 1520 | 1670 | 1820 | 1970 | 2120 | 10t |

| 1220x150x50 | 150 | 50 | 1220 | 1370 | 1520 | 1670 | 2270 | 2420 | 2570 | 5t |

| 1220x150x60 | 150 | 60 | 1220 | 1370 | 1520 | 1670 | 2270 | 2420 | 2570 | 6t |

| 1220x150x65 | 150 | 65 | 1220 | 1370 | 1520 | 1670 | 2270 | 2420 | 2570 | 7t |

| 1220x170x70 | 170 | 70 | 1220 | 1370 | 1520 | 1670 | 2270 | 2420 | 2570 | 8t |

| 1220x175x80 | 175 | 80 | 1220 | 1370 | 1520 | 1670 | 2270 | 2420 | 2570 | 10t |

Types of Polyurethane Fork Protection Products We Customized

- Forklift Fork Covers / Polyurethane Fork Covers

- Fork Sleeves for Forklifts / Urethane Fork Sleeves

- Fork Tip Protectors / Forklift Fork Tip Protectors

- Fork Blade Protectors / Fork Protectors for Forklifts

Related Products

Request a Quote for Custom Polyurethane Fork Covers / Sleeves

Looking for the perfect fit for your forklift? At Lisen, we specialize in custom polyurethane fork covers and sleeves designed to match your specific equipment and operational needs.

Polyurethane forklift sleeves are designed to fit a wide range of equipment, including electric forklifts, fuel forklifts, pallet trucks, stackers, and trailers. Whether in logistics warehouses, construction sites, or port terminals, these sleeves deliver reliable protection, extending equipment life and reducing product damage.

Simply share your forklift fork dimensions, load requirements, and working environment, and our team will create a tailored solution that ensures maximum protection, durability, and efficiency.

Polyurethane offers superior abrasion and tear resistance compared with rubber and is lighter and non-corroding compared with metal. It’s non-marking, more impact-absorbing, and typically lasts longer — lowering replacement frequency and product damage.

Yes. We manufacture custom polyurethane fork covers to your fork width, height, thickness, hole pattern, hardness, and color. Customization ensures a snug fit, correct load capacity, and compatibility with clamps or attachments.

Typical hardness ranges from Shore A ~70–95. Thicknesses commonly range from 30mm to 80mm or more depending on application. We’ll recommend a hardness/thickness balance based on load type (fragile vs. heavy), operating temperature, and abrasion exposure.

Most polyurethane fork covers slide on and secure with a clamp, pin, or adhesive. They require minimal maintenance: periodic inspection for cuts/wear, occasional cleaning with mild detergent, and re-installation if shifted. Damaged sleeves should be replaced promptly.

Lifespan depends on duty cycle, load type, and environment. Under typical warehouse use, polyurethane fork covers often last significantly longer than rubber—commonly months to years. Heavy abrasion or sharp loads shorten life.