Polyurethane Idler Rollers

Polyurethane idler rollers are industrial parts made of polyurethane. They usually install in belt conveyors, chain conveyors and other drive systems. Although idler rollers don’t provide power drive, they support and guide belts or chains to run smoothly. They help belts maintain the right running track, prevent belt misalignment, and ensure smooth and efficient material conveyance.

Custom Polyurethane Idler Rollers Manufacturers

Applications of Urethane Idler Rollers

- Automobile Manufacturing Industry;

- Electronic Equipment Manufacturing Industry;

- Agricultural Machinery Industry - Used in belt drive systems of agricultural machinery like harvesters, planters and other equipment.

- Logistics and Warehousing Industry - Applied in conveyor belt systems of logistics centers and warehousing facilities.

- Food Processing Industry;

- Conveyor Belt Manufacturers and Producers, and All Kinds of Industrial Drive System Machinery and Equipment Manufacturing Industry.

Feature of Polyurethane Idler Rollers

Polyurethane idler rollers possess high elasticity. They can cushion the impact force generated during the belt's running, effectively reducing the vibration and noise during equipment operation.

Meanwhile, these rollers feature good abrasion resistance, oil resistance, and chemical corrosion resistance. They can operate stably in harsh industrial settings, endure the friction between the belt and the idler roller surface, extend the equipment's service life, and cut down maintenance costs.

Industrial Polyurethane Idler roller Manufacturers

- Product Specifications

- Gallery

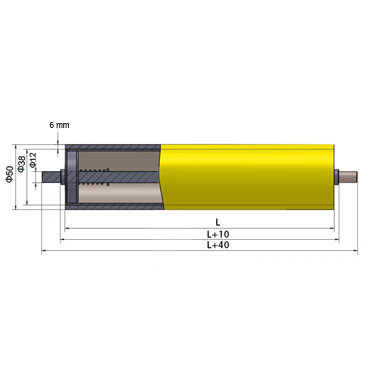

Polyurethane Coated Idler Rollers Structure

Polyurethane coated idler rollers can be designed in either a solid or hollow structure. Compared to solid idler rollers, hollow idler rollers are lighter in weight and have a smaller rotational inertia. This characteristic enables them to reduce the driving power required by the motor, thereby achieving energy savings. As a result, they are particularly suitable for conveying light materials or in applications where energy conservation is a high priority.

Custom Manufacturing Capabilities

We utilize various polyurethane molding technologies and processing methods to manufacture polyurethane rollers in a wide range of shapes and sizes. This allows us to meet the diverse design requirements of different industries and equipment.

Polyurethane Formulas and Performance Table

Here, we present our different series of polyurethane formulas along with the performance table of polyurethane elastomers.

Polyester polyol/TDI series prepolymer

| Model | D3136 | D3145 | D3160 |

| NCO content / % | 3.6±0.1 | 4.5±0.2 | 6.0±0.2 |

| State of matter At 20℃ | White waxy solid | White waxy solid | White waxy solid |

| MOCA 100g prepolymer dosage /g | 10.5 | 13.2 | 17.2 |

| Viscosity(85℃)/ mpa * s | 1800 | 1200 | 900 |

| Mixing Temperature /℃(prepolymer/MOCA) | 85/120 | 80/120 | 75/120 |

| Gel time /min | 9 | 7.5 | 5 |

| Post vulcanization time (100℃)/h | 10 | 10 | 10 |

| Hardness ( shore A) | 85±1 | 91±1 | 96A±1 (54D) |

| 100% constant tensile stress /MPa | 4.2 | 6.7 | 11.5 |

| 300% constant tensile stress /MPa | 8.3 | 12.5 | 21.3 |

| Tensile strength /MPa | 48 | 52 | 55 |

| Elongation at break / % | 670 | 610 | 530 |

| Tear strength (right angle) /(KN/m) | 75 | 95 | 124 |

| Tear strength (pants type) /(KN/m) | 34 | 42 | 49 |

| Rebound /% | 39 | 32 | 33 |

| Density (25℃)/(g/cm) | 1.26 | 1.27 | 1.29 |

| wearing out by friction mm³ | 40 | 48 | 57 |

Polyether polyols PTMG series prepolymer

| Model | D2135 | D2142 | D3160 |

| NCO content / % | 35±0.1 | 4.2±0.2 | 6.2±0.2 |

| State of matter At 20℃ | White waxy solid | White waxy solid | White waxy solid |

| MOCA 100g prepolymer dosage /g | 10 | 12.1 | 18 |

| Viscosity(85℃)/ mpa * s | 1200 | 750 | 480 |

| Mixing Temperature /℃(prepolymer/MOCA) | 85/120 | 85/120 | 80/120 |

| Gel time /min | 11 | 10 | 6 |

| Post vulcanization time (100℃)/h | 10 | 10 | 10 |

| Hardness ( shore A) | 85±2 | 90±1 | 95A±1 (49D±2) |

| 100% constant tensile stress /MPa | 5.4 | 7.5 | 12.8 |

| 300% constant tensile stress /MPa | 9.6 | 14.1 | 36.3 |

| Tensile strength /MPa | 27 | 33 | 48 |

| Elongation at break / % | 550 | 500 | 350 |

| Tear strength (right angle) /(KN/m) | 65 | 78 | 95 |

| Tear strength (pants type) /(KN/m) | 21 | 28 | 33 |

| Rebound /% | 61 | 54 | 47 |

| Density (25℃)/(g/cm) | 1.07 | 1.09 | 1.13 |

MDI series prepolymer

| Model | D3560M |

| NCO content / % | 6.0 |

| Viscosity(80℃)/ mpa * s | 1780 |

| D3560M : D3575-C | 100:6.1 |

| Gel time /min | 8-11 |

| Post vulcanization time (100℃)/h | 48 |

| Hardness ( shore A) | 83±3 |

| Tensile strength /MPa | 46 |

| Elongation at break / % | 580 |

| Tear strength (right angle) /(KN/m) | 82 |

| Rebound /% | 38 |

| Density (25℃)/(g/cm) | 1.2 |

Related Products

Polyurethane Idler Roller Manufacturers

Our polyurethane idler Rollers are made of wear-resistant polyurethane materials. These materials provide excellent wear and aging resistance to ensure long term stable operation.

Our idlers rollers are dimensionally accurate and can be seamlessly integrated into a variety of conveyor systems to provide you with reliable conveyor support.

We offer comprehensive customization services for conveyor idler rollers. Whether it's dimensional accuracy, hardness, color, surface finish or performance, we can meet your requirements for drive train equipment component repair or replacement. We are committed to providing you with custom urethane roller services and urethane molding solutions to fully meet your specific needs.

Of course you can. We specialize in customized service, no matter you need special size, shape or performance of polyurethane idler rollers, our professional team can accurately design and produce according to your requirements to meet your individual needs.

The cycle time of customization depends on the complexity of the product. In general, simple customization can be completed within [15-20] working days; for complex customization projects, we will give you specific time after communicating and confirming with you, and ensure on-time delivery.

The price mainly depends on the product size, material, process complexity and other factors. After you provide detailed requirements, our sales team will quickly account for the exact price for you and provide a competitive quotation program.

We provide perfect after-sales guarantee. The product warranty period is 6 month, and we will repair or replace it if there is any quality problem during the warranty period. Meanwhile, we have a professional after-sales team to provide you with technical support and service at any time.

Our polyurethane idler rollers are made of high quality polyurethane formula and mature polyurethane molding technology, under high intensity friction environment, the abrasion resistance and service life is 3-5 times longer than rubber rollers, which can save your cost and time for frequent replacement.