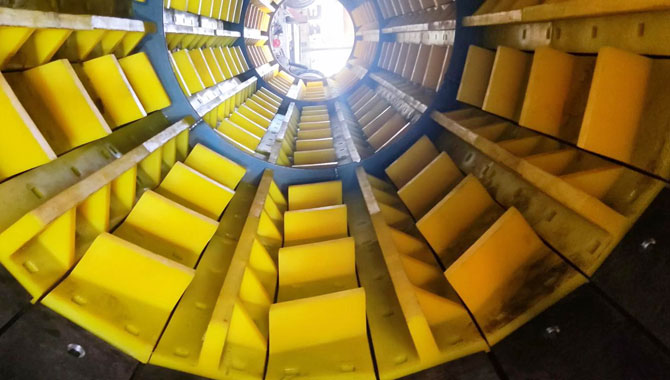

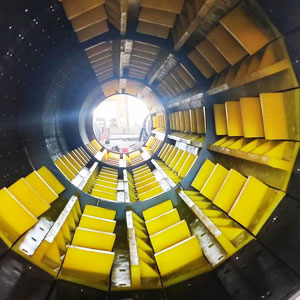

Polyurethane Liner

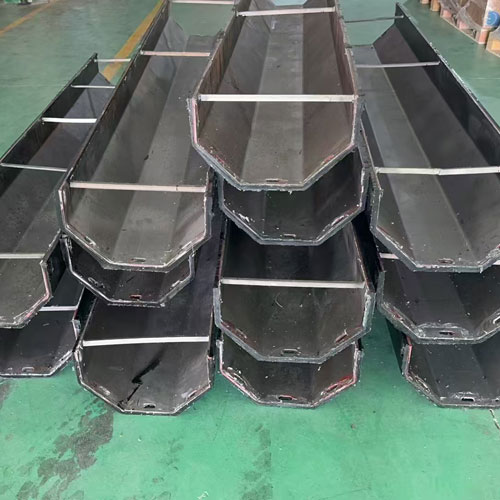

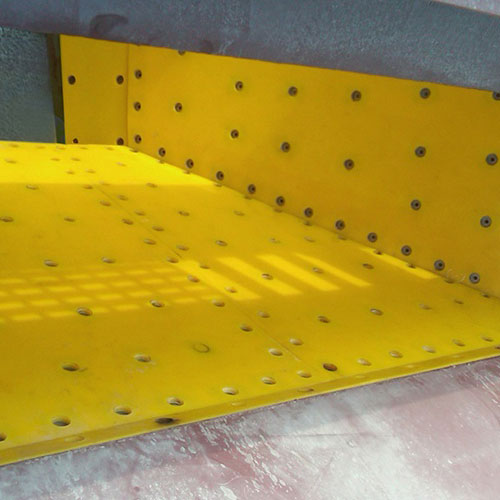

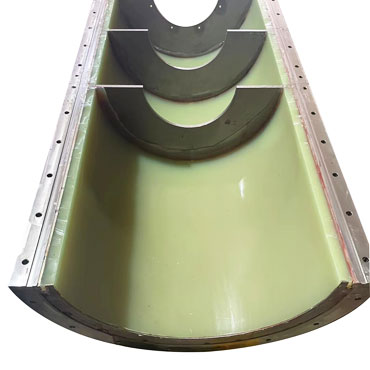

Polyurethane liners are essential for industries demanding exceptional wear resistance, durability, and performance in harsh conditions. Our range of pre-molded polyurethane liners offers lasting protection for mining, manufacturing, and material handling equipment. From polyurethane mining liners to grinding mill linings and hydrocyclone liners, we provide customized solutions tailored to meet your needs.

Polyurethane Liners for Industrial Wear Protection

Why Choose Polyurethane Liners?

- Superior Wear Resistance: Polyurethane liners outperform rubber and plastic, providing longer service life in the toughest environments.

- Customizable Solutions: We offer custom-molded polyurethane liners in various hardness levels, shapes, and sizes to meet your exact application needs.

- Cost-Effective: Our polyurethane liners reduce the frequency of replacement and maintenance, extending machinery lifespan and lowering operational costs.

Application of Polyurethane Liner

- Conveyor Systems: Protect and extend the life of conveyor belts and components.

- Mining Equipment: Guard against heavy abrasion in mining machinery.

- Cement and Aggregate Plants: Line chutes, hoppers, and other high-wear parts.

- Bulk Material Handling: Protect truck beds, bins, and pipes in bulk handling systems.

- Grinding Mills: Improve efficiency and reduce wear in ball mills and other grinding equipment.

Pre-molded Polyurethane Linings for Mining, Milling, and Grinding Applications

- Product Specifications

- Gallery

| Specification | Details |

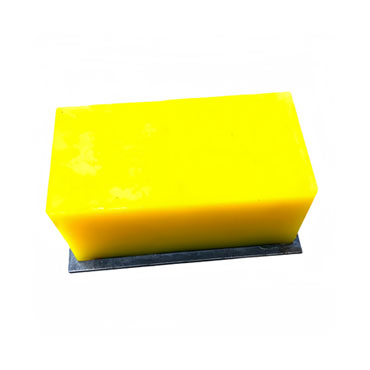

| Material | High-quality Polyurethane (Cast or Molded) |

| Hardness Range | Shore A 60-98 (Custom options in Shore D available) |

| Thickness | Customizable based on application needs |

| Inner Diameter (ID) | Customizable to suit different pipe sizes or equipment |

| Outer Diameter (OD) | Customizable based on system requirements |

| Length/Width | Customizable according to equipment design and operational parameters |

| Tensile Strength | High tensile strength to withstand mechanical stress |

| Abrasion Resistance | Superior to rubber and plastic for high-wear environments |

| Impact Resistance | Excellent impact resistance for high-wear applications |

| Temperature Resistance | Standard: -30°C to +80°C (Extended ranges available) |

| Chemical Resistance | Resistant to oils, fats, greases, lubricants, and most industrial chemicals |

| Color Options | Yellow, Red, Black, Blue (Custom colors available) |

| Dimensional Tolerance | Tight tolerances based on customer specifications |

| Load-Bearing Capacity | High, ideal for heavy-duty and continuous operations |

| Manufacturing Process | Cast Polyurethane (for thicker liners) / Molded Polyurethane (for precision)/ Bonded Polyurethane to steel |

| Customization | Full customization for hardness, size, and formulation |

| Operating Conditions | Suitable for static and dynamic applications, including abrasive conditions |

| Moisture Resistance | Hydrolysis-resistant formulations available for wet environments |

| Production Volume | Small batch to high-volume OEM supply |

| Typical Applications | Conveyor systems, mining, cement plants, bulk material handling, industrial machinery |

Related Products

Why Choose Us?

As a trusted manufacturer of polyurethane liners, we are committed to delivering high-quality, tailored solutions that optimize performance and reduce costs.

- Tailored Solutions: Our engineering team works with you to design custom polyurethane liners that meet your specific requirements.

- Consistent Quality: Using advanced molding techniques, we ensure uniformity, tight tolerances, and superior wear protection.

- Long-Term Partnerships: We’re dedicated to supporting your operational efficiency and long-term cost reduction goals.

Polyurethane liners are essential in industries such as mining, cement, steel, bulk material handling, and more. They excel in high-wear, heavy-duty applications and environments exposed to chemicals or extreme conditions.

Polyurethane liners offer superior abrasion resistance, impact strength, and load-bearing capacity, providing longer service life and reduced maintenance costs compared to rubber or plastic liners.

Yes, we offer fully customizable polyurethane liners in terms of hardness, size, formulation, and other specifications to meet your specific needs.

Polyurethane liners last significantly longer than rubber or plastic alternatives. With proper selection based on environmental conditions, they can provide years of reliable service, reducing downtime and maintenance costs.

The appropriate hardness depends on the application. For high-impact or abrasive conditions, a higher Shore A rating (80A–98A) is ideal. We can assist you in selecting the right hardness based on your specific needs.