Polyurethane Mounts

Our polyurethane mounts offer superior vibration control, impact resistance, and durability compared to rubber. You can use them in automotive engines, motors, transmissions, or body applications. Each urethane mount is designed to withstand demanding operating conditions.

High Performance & Durability Polyurethane Mounts

Why Choose Polyurethane Mounts Over Rubber?

Unlike traditional rubber, polyurethane mounts resist oil, grease, chemicals, and high loads. They last longer, reduce downtime, and provide consistent performance in both automotive and industrial applications. Whether you’re upgrading to poly engine mounts or sourcing polyurethane motor mounts for machinery, our solutions deliver unmatched reliability.Industries That Rely on Our Polyurethane Mounts

- Automotive & Motorsport (engine, motor, transmission upgrades)

- Heavy Machinery & Construction Equipment

- Manufacturing & Industrial Machinery

- Agricultural & Mining Equipment

Custom Urethane Mounts for Industrial Applications

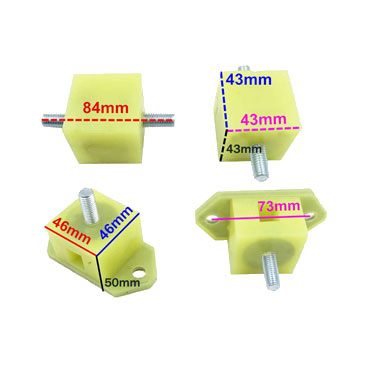

- Product Specifications

- Gallery

Key Feature of Our Polyurethane Mounts

- Reduce vibration, noise, and wear

- Improve equipment stability and durability

- Urehtane mounts can alternatives to rubber mounts

- Custom urethane mounts for your application

Types of Polyurethane Mounts We Offer

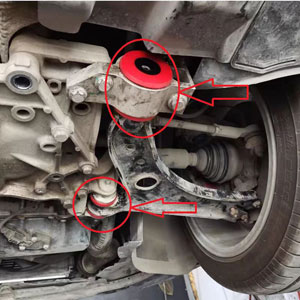

- Polyurethane Engine Mounts / Urethane Engine Mounts – Designed for automotive and heavy-duty vehicles, reducing vibration and enhancing power transfer.

- Polyurethane Motor Mounts / Poly Motor Mounts – Ideal for industrial machinery and equipment.

- Polyurethane Transmission Mounts – Strong, oil-resistant mounts for drivetrain stability.

- Polyurethane Body Mounts – Heavy-duty replacements for rubber body mounts in trucks and off-road vehicles.

Polyurethane Mounts vs. Rubber Mounts – Specification Comparison

| Property | Polyurethane Mounts | Rubber Mounts |

| Durability | High abrasion & wear resistance; long service life in harsh environments | Prone to cracking, tearing, and faster degradation |

| Load Capacity | Supports heavier loads; customizable durometer (Shore A 60–98, Shore D 50–70) | Limited load-bearing capacity; softer durometer range |

| Vibration & Shock Absorption | Excellent damping with higher resilience; consistent over time | Good initial damping but degrades with aging |

| Temperature Resistance | -30°C to +80°C (special grades up to +110–120°C) | -20°C to +70°C (reduced performance at extremes) |

| Chemical Resistance | Resistant to oils, fuels, solvents, ozone, and industrial chemicals | Poor resistance to oils, fuels, and ozone |

| Bonding Options | Easily bonded to metal inserts, studs, or plates for custom mounting solutions | Limited bonding options; weaker adhesion over time |

| Service Life | Longer lifespan, especially in demanding industrial and automotive applications | Shorter lifespan under continuous stress or exposure |

| Applications | Engine mounts, motor mounts, transmission mounts, industrial equipment, heavy machinery | Light-duty automotive and general equipment |

Related Products

Request a Quote for Polyurethane Mounts

Looking for durable, high-performance urethane mounts? Partner with a proven urethane parts manufacturer that delivers precision-engineered polyurethane molded parts for your application. Contact us today to request a quote for polyurethane mounts tailored to your performance and durability needs.

Polyurethane mounts isolate vibration and shock like rubber but offer higher load capacity, better abrasion/chemical resistance, and longer service life—especially in oily, high-temperature, or high-duty cycles.

Engine/motor/transmission mounts, body/chassis mounts, pumps, compressors, HVAC, conveyors, presses, packaging machinery, off-road equipment, and agricultural/mining machinery.

Yes. Provide load (static/dynamic), frequency range, displacement limits, operating temperature, environment (oil/chemicals), geometry/space, durometer target, and quantity/target life.

Typically Shore A 60–98 and Shore D 50–70 for stiffer designs. We recommend durometer based on load/deflection and desired isolation frequency.

Yes. We mold to metal plates/inserts, studs, or sleeves using engineered primers/adhesives for high peel and shear strength.