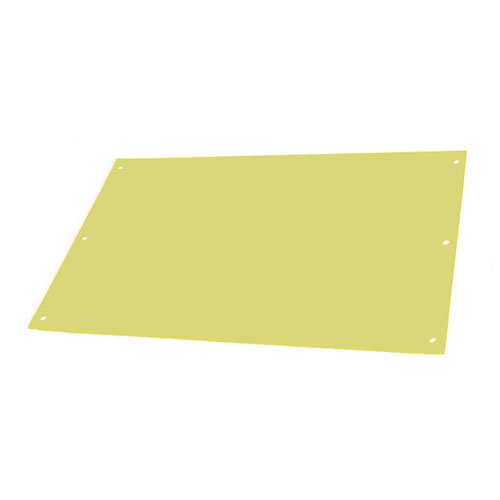

Polyurethane Pads

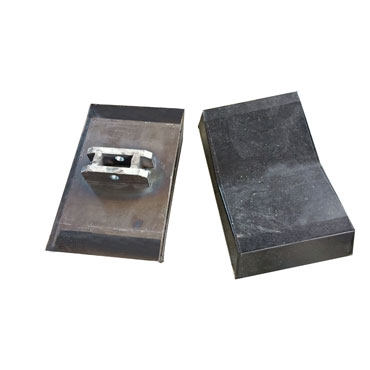

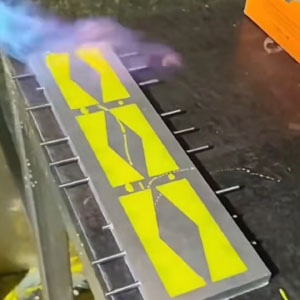

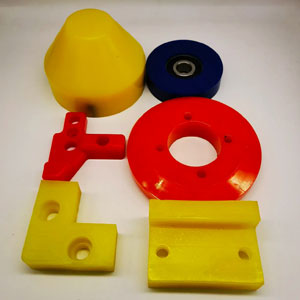

Polyurethane pads—also known as urethane pads or PU pads—deliver outstanding wear resistance, impact absorption, and vibration damping. These custom cast polyurethane pads perform reliably in demanding industrial and OEM environments. They protect machinery, extend component life, and improve system stability in applications such as vibration isolation, mounting, and impact protection.

Custom Polyurethane Pads | Urethane Pads & PU Pads Manufacturer

Why Choose Polyurethane Pads

- Superior abrasion and wear resistance compared to rubber or plastic;

- Excellent impact and vibration absorption;

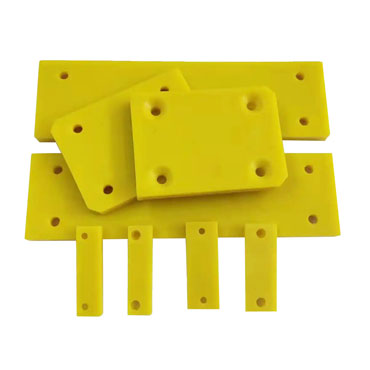

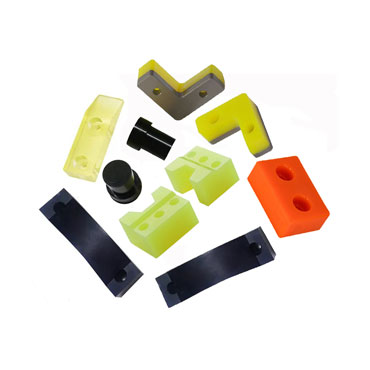

- Custom hardness, size, and shape to meet specific application needs;

- Non-marking and chemical-resistant properties;

- Extended service life with reduced maintenance costs.

Applications of PU Pads

- Heavy machinery and industrial equipment;

- Automotive and material handling systems;

- Construction and mining equipment;

- Presses, conveyors, and production lines;

- Hydraulic and vibration control systems.

Polyurethane Impact, Shock & Vibration Control Pads

- Product Specifications

- Gallery

| Specification | Details / Range |

| Material | High-quality polyurethane (PU) for durability and wear resistance |

| Hardness (Shore A) | 60A – 95A (custom urethane pads available per application) |

| Tensile Strength | 15–35 MPa |

| Elongation at Break | 250–600% |

| Abrasion Resistance | Superior to rubber and standard plastics; ideal for polyurethane wear pads |

| Temperature Range | -40°C to +120°C (custom formulations up to +150°C) |

| Chemical Resistance | Resistant to oils, greases, solvents, and mild acids |

| Load Bearing Capacity | High, adjustable with thickness and density |

| Impact Resistance | Excellent for polyurethane impact pads and shock absorption |

| Vibration Isolation | Reduces vibration and noise (polyurethane vibration isolators / damping pads) |

| Wear Resistance | Long service life under heavy load and continuous operation |

| Dimensions | Thickness: 5–100 mm; Length/Width: customizable |

| Shape Options | Square, rectangular, circular, cylindrical, or custom-molded (custom polyurethane pads / cast polyurethane pads) |

| Surface Finish | Smooth, textured, or ribbed |

| Custom Design | Available for OEM requirements: cutouts, grooves, reinforcement |

| Product Types | Standard PU pads, custom polyurethane pads, cast polyurethane pads, urethane coil pads / coil storage pads, polyurethane track pads / poly track pads, urethane machine/equipment pads, polyurethane pad liners, polyurethane wear pads |

| Applications | Industrial machinery, conveyors, chutes, presses, hydraulic systems, tracked vehicles, automation equipment, heavy-duty OEM machinery |

Related Products

Get a Custom Polyurethane Pad Solution for Your Application

Partner with LISEN for custom polyurethane pads that match your equipment’s performance needs. Contact us today for tailored design, fast production, and reliable quality that keeps your operation running smoothly.

Polyurethane pads provide superior wear resistance, higher load-bearing capacity, excellent vibration damping, and longer service life, making them more durable and reliable than standard rubber or plastic alternatives.

Industries such as manufacturing, construction, mining, material handling, and food processing rely on polyurethane pads for equipment mounting, machinery protection, conveyors, and vibration isolation. Their versatility suits a wide range of industrial applications.

Polyurethane pads come in standard sizes and can be custom-molded to any shape, including square, rectangular, circular, cylindrical, or specialty profiles to meet OEM and industrial specifications.

Yes. Custom polyurethane pads can be tailored to specific size, hardness, shape, and formulation requirements, ensuring optimal performance for unique machinery or industrial setups.

Selecting the appropriate urethane pad involves considering load requirements, environmental conditions, vibration levels, and desired durability. Our team can provide guidance to ensure optimal performance for your machinery.