Polyurethane & Urethane Parts Manufacturer – Custom & Molded Solutions

As a leading urethane parts manufacturer, we specialize in producing durable, high-performance polyurethane parts that outperform rubber and metal in demanding environments. From molded solutions to cast components, our custom urethane parts are engineered to reduce downtime, extend equipment life, and deliver reliable performance across industries.

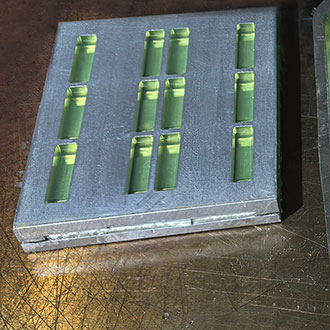

We offer complete molded polyurethane parts and cast urethane parts manufacturing services, from rapid prototyping to full-scale production. Our expertise in custom molding solutions allows us to tailor durometer, geometry, and formulations to match your exact requirements, ensuring precision, consistency, and cost-effectiveness. Whether it’s a one-off replacement or large-scale OEM supply, our polyurethane molded parts deliver long-lasting performance you can rely on—backed by decades of material expertise and engineering support.

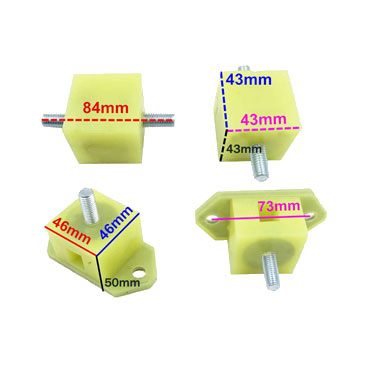

Shock Absorption & Vibration Control PU Parts

These polyurethane parts and components are designed to absorb shocks, reduce vibrations, and protect machinery or structures. They are used to control energy transfer and increase system longevity in industries like automotive, industrial machinery, and heavy-duty applications.

Our polyurethane buffers deliver superior energy absorption and long service life, protecting machinery from impact damage. Ideal for heavy-duty equipment, they reduce downtime and extend lifespan, outperforming traditional rubber in harsh environments.

Durable polyurethane bumpers safeguard vehicles, machinery, and material handling equipment from repeated impact. Designed for industrial and logistics applications, they combine excellent shock resistance with wear durability, reducing replacement costs and equipment damage.

design for demanding environments, urethane bumper stops prevent over-travel, absorb shock, and control motion. They’re ideal for automotive, industrial, and loading dock applications, offering consistent performance and reduced noise compared to conventional materials.

Polyurethane shock absorbers minimize vibration and sudden impacts in automotive, aerospace, and heavy equipment. With customizable hardness and load ratings, they ensure smoother operation, protect sensitive components, and deliver a longer-lasting solution than standard rubber absorbers.

High-performance polyurethane springs provide excellent load-bearing, shock absorption, and resilience under compression. Perfect for presses, stamping machines, and vibration systems, they resist fatigue and outperform steel and rubber springs in demanding industrial applications.

Our polyurethane mounts isolate vibration and noise in machinery, HVAC systems, and vehicles. Built to withstand heavy loads, oils, and chemicals, they extend equipment life while improving operator comfort and performance.

Our custom urethane bushings deliver superior vibration damping and shock absorption for suspension systems, machinery, and heavy equipment. Available in custom hardness and sizes, they provide long-lasting performance, reduced maintenance, and improved stability in high-load, high-motion applications.

Urethane stoppers are engineered for impact absorption, sealing, and positioning in industrial machinery and tooling. Their wear resistance and resilience outperform rubber, making them ideal for precision applications that require long service life, reduced downtime, and reliable performance under repeated stress.

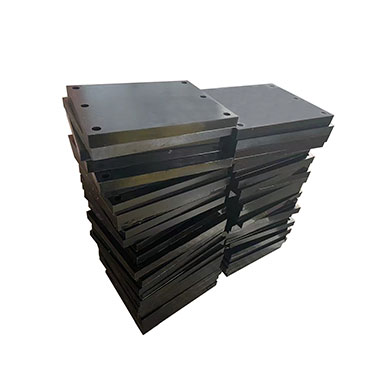

Wear Resistance & Durability PU Parts

These polyurethane parts are engineered for high abrasion and wea resistance.They are ideal for protecting surfaces and ensuring the longevity of machines or components in high-friction environments.

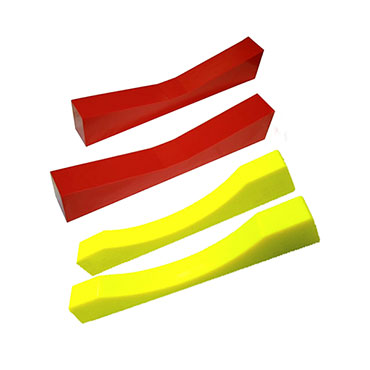

Printing & Textile Industrial PU Parts

Polyurethane squeegees are essential for screen printing and textile applications, offering excellent solvent, oil, and chemical resistance. With consistent edge durability, they ensure sharp prints, reduced downtime, and longer service life compared to conventional rubber blades.

Spacing and Connecting Transmission Mechanical Components

Precision polyurethane spacers and couplings ensure accurate alignment, secure load transfer, and vibration control in mechanical assemblies, enhancing durability and performance across industrial, automotive, and OEM transmission systems.

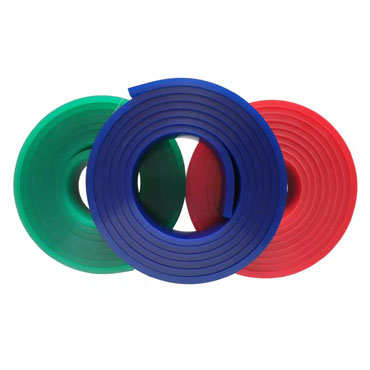

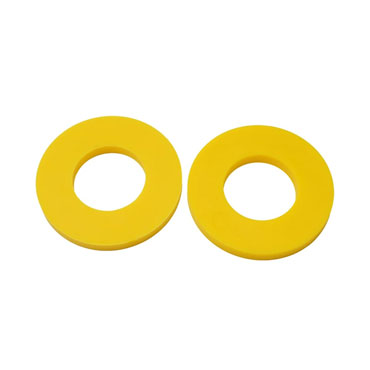

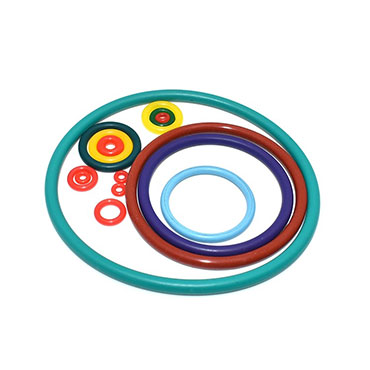

Sealing Washers & Gaskets Polyurethane Parts

Polyurethane sealing parts are designed to prevent leaks, absorb shocks, and provide tight fits in industrial systems. Seals, washers,gaskets, rings deliver chemical resistance, flexibility, and precision. They are widely used in automotive, hydraulic, pneumatic, and general machinery applications to ensure safety and operational reliability.

Polyurethane Parts Features

Reduce downtime and replacement costs with long-lasting urethane parts.

Cast, molded, or machined PU parts to meet your exact specifications.

Protect machinery and ensure smooth performance under heavy loads.

Polyurethane (PU) parts provide excellent resistance to oils, greases, ozone, weathering, and water.

Why Choose Polyurethane Parts Over Rubber & Metal?

Polyurethane offers unique advantages that make it the preferred material for industrial and OEM applications. Unlike rubber, polyurethane parts provide superior wear resistance, load-bearing capacity, and chemical resistance. Compared to metal, they offer lightweight flexibility, noise reduction, and better shock absorption.

Whether you need abrasion resistance, impact protection, or vibration control, urethane parts deliver the perfect balance of strength and versatility.

Custom-Molded Urethane Parts for OEMs & Industrial Applications

For customers with unique requirements, we offer custom urethane parts tailored to your exact specifications. From prototypes to large-scale production runs, our engineering team works closely with OEMs, equipment manufacturers, and industrial clients to deliver precision custom molded urethane parts that meet strict performance standards.

With customizable hardness, shape, and size options, we ensure every part is optimized for its application.

Cast & Molded Polyurethane Parts – Flexible Manufacturing Options

We provide both cast urethane parts and molded polyurethane parts, offering flexibility to suit project needs. Cast urethane is ideal for low- to mid-volume runs, complex shapes, and cost-effective tooling, while molded polyurethane excels in high-volume production with consistent quality and tight tolerances. This dual capability allows us to serve a wide range of industries with both speed and accuracy.

Our Range of Urethane & Polyurethane Parts

We manufacture a wide selection of standard and molded polyurethane parts to meet diverse customer needs. Our product range includes bushings, bumpers, pads, rollers, seals, washers, couplings, sheets, rods, tubes, and blocks.

Each component is engineered for durability and precision, helping customers improve efficiency and reduce maintenance costs.

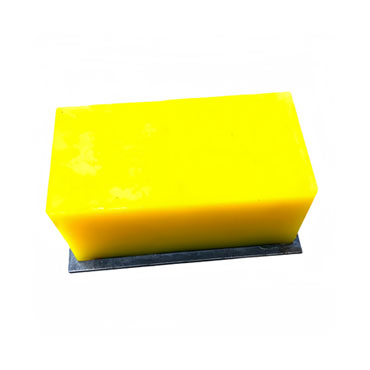

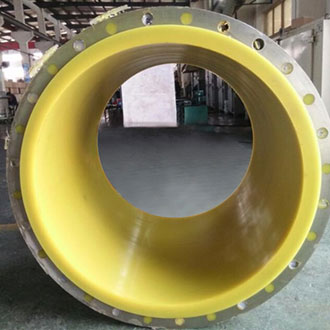

Structural & Mechanical Parts Polyurethane

PU sheet, rods, bar, tubes, plate, block are used for machinery components, fabrication, or custom mechanical parts. all these PU parts serve as base materials for structural or mechanical applications. Special sizes and hardness can be customized according to your requirements.

Polyurethane sheets offer high strength, abrasion resistance, and flexibility for industrial cutting, lining, and protective applications. Their versatility makes them ideal replacements for rubber, plastics, and metals in demanding environments.

Polyurethane rods and bars are durable, machinable PU materials for industrial and OEM use, offering excellent wear resistance, impact strength, and consistent performance for custom machined components.

Polyurethane pipes are rigid, machinable industrial PU components available in cast or extruded forms, designed for wear resistance, dimensional accuracy, and OEM applications such as rollers, bushings, sleeves, and spacers.

Polyurethane blocks serve as raw material for custom machining or cushioning components. With excellent load-bearing capacity and wear resistance, they’re used in tooling, protective parts, and high-impact applications across industries.

Custom Urethane Parts Manufacturers

- PU Parts Gallery

- Specifications of Polyurethane Parts

- Polyurethane Raw Material Technical Parameter Table

Polyurethane parts are engineered for durability, flexibility, and superior wear resistance, making them the preferred choice across industries where rubber or metal fall short. As leading urethane parts manufacturers, we produce a wide range of polyurethane parts and urethane parts designed to withstand abrasion, impact, and chemical exposure.

Our expertise covers molded polyurethane parts, polyurethane molded parts, and cast urethane parts, giving customers the freedom to choose between precision-molded designs for complex geometries or cast solutions for larger, high-load applications. For OEMs and industrial clients requiring unique performance, we specialize in custom urethane parts tailored to exact specifications—whether it’s hardness, load capacity, or chemical resistance.

With versatility in material formulation and advanced molding techniques, our urethane parts deliver reliable performance in demanding environments, offering longer service life and cost efficiency.

Industries We Serve

Our polyurethane molded parts are trusted by customers worldwide in industries such as:

- Automotive & Transportation – shock absorbers, bushings, mounts

- Mining & Construction – liners, pads, wear-resistant parts

- Aerospace – vibration control, seals, precision components

- Material Handling & Logistics – rollers, couplings, conveyor parts

- Printing & Textile – polyurethane squeegees and industrial scrapers

Wherever performance and reliability are critical, our urethane parts deliver proven solutions.

Polyester polyol/TDI series prepolymer

| Model | D3136 | D3145 | D3160 |

| NCO content / % | 3.6±0.1 | 4.5±0.2 | 6.0±0.2 |

| State of matter At 20℃ | White waxy solid | White waxy solid | White waxy solid |

| MOCA 100g prepolymer dosage /g | 10.5 | 13.2 | 17.2 |

| Viscosity(85℃)/ mpa * s | 1800 | 1200 | 900 |

| Mixing Temperature /℃(prepolymer/MOCA) | 85/120 | 80/120 | 75/120 |

| Gel time /min | 9 | 7.5 | 5 |

| Post vulcanization time (100℃)/h | 10 | 10 | 10 |

| Hardness ( shore A) | 85±1 | 91±1 | 96A±1 (54D) |

| 100% constant tensile stress /MPa | 4.2 | 6.7 | 11.5 |

| 300% constant tensile stress /MPa | 8.3 | 12.5 | 21.3 |

| Tensile strength /MPa | 48 | 52 | 55 |

| Elongation at break / % | 670 | 610 | 530 |

| Tear strength (right angle) /(KN/m) | 75 | 95 | 124 |

| Tear strength (pants type) /(KN/m) | 34 | 42 | 49 |

| Rebound /% | 39 | 32 | 33 |

| Density (25℃)/(g/cm) | 1.26 | 1.27 | 1.29 |

| wearing out by friction mm³ | 40 | 48 | 57 |

Polyether polyols PTMG series prepolymer

| Model | D2135 | D2142 | D3160 |

| NCO content / % | 35±0.1 | 4.2±0.2 | 6.2±0.2 |

| State of matter At 20℃ | White waxy solid | White waxy solid | White waxy solid |

| MOCA 100g prepolymer dosage /g | 10 | 12.1 | 18 |

| Viscosity(85℃)/ mpa * s | 1200 | 750 | 480 |

| Mixing Temperature /℃(prepolymer/MOCA) | 85/120 | 85/120 | 80/120 |

| Gel time /min | 11 | 10 | 6 |

| Post vulcanization time (100℃)/h | 10 | 10 | 10 |

| Hardness ( shore A) | 85±2 | 90±1 | 95A±1 (49D±2) |

| 100% constant tensile stress /MPa | 5.4 | 7.5 | 12.8 |

| 300% constant tensile stress /MPa | 9.6 | 14.1 | 36.3 |

| Tensile strength /MPa | 27 | 33 | 48 |

| Elongation at break / % | 550 | 500 | 350 |

| Tear strength (right angle) /(KN/m) | 65 | 78 | 95 |

| Tear strength (pants type) /(KN/m) | 21 | 28 | 33 |

| Rebound /% | 61 | 54 | 47 |

| Density (25℃)/(g/cm) | 1.07 | 1.09 | 1.13 |

MDI series prepolymer

| Model | D3560M |

| NCO content / % | 6.0 |

| Viscosity(80℃)/ mpa * s | 1780 |

| D3560M : D3575-C | 100:6.1 |

| Gel time /min | 8-11 |

| Post vulcanization time (100℃)/h | 48 |

| Hardness ( shore A) | 83±3 |

| Tensile strength /MPa | 46 |

| Elongation at break / % | 580 |

| Tear strength (right angle) /(KN/m) | 82 |

| Rebound /% | 38 |

| Density (25℃)/(g/cm) | 1.2 |

Request a Quote for Your Urethane Parts Project

Looking for a reliable urethane parts manufacturer to support your project? Whether you need standard polyurethane parts, custom urethane parts, or precision polyurethane molded parts, we are ready to help. Our team provides expert engineering, fast turnaround, and cost-effective solutions for OEMs and industrial clients.

Contact us today to request a quote and discover why leading companies choose our cast and molded polyurethane parts.

Choose cast urethane parts for low–mid volumes, larger sizes, thick sections, or special durometers/blends. Choose molded polyurethane parts (injection/compression) for tighter tolerances, thin walls, complex detail, and high-volume repeatability.

We formulate custom urethane parts from ~Shore A 20 to Shore D 80, covering soft, impact-absorbing grades up to rigid, load-bearing compounds. We’ll recommend hardness based on load, speed, temperature, and environment.

Send drawings (STEP/IGES/PDF), quantities, target durometer, operating loads/speeds, temperature, chemicals, color, and any certifications (e.g., FDA, REACH, RoHS). We’ll advise process (cast vs. molded), tooling, price, and timeline.

Yes—CNC finish-machining, grinding, bonding to metal hubs/plates, insert overmolding, surface texturing, and precision trimming. This is how we achieve tight bores, keyed features, and controlled runout on polyurethane molded parts.

Cost depends on tooling, volume, part size, material grade, and secondary ops. Cast urethane minimizes tooling cost for small runs; molded polyurethane reduces unit cost at higher volumes.