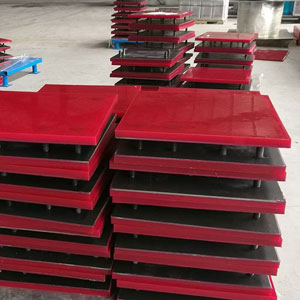

Polyurethane Plate

Polyurethane plates are high-performance, wear-resistant materials designed for industrial use. Ideal for machining, custom fabrication, or conveyor systems, these PU plates reduce downtime, protect equipment, and extend component life. Available in various thicknesses, hardness levels, and custom sizes, they meet the needs of OEMs, maintenance teams, and heavy-duty operators.

Polyurethane Plates – Wear-Resistant PU for Industrial & Conveyor Applications

Why Choose Our Polyurethane Plates?

- Exceptional abrasion and impact resistance;

- Custom thickness, hardness, and size options;

- Machinable and durable for long-term use;

- Reduce equipment wear, downtime, and maintenance costs;

- Suitable for conveyor, manufacturing, and heavy-duty industrial applications.

Applications of Polyurethane Plates

- Conveyor system wear protection;

- Bulk material handling abrasion zones;

- Chutes, hoppers, and guide wear plates;

- Custom parts for OEM machinery;

- Reducing maintenance costs and downtime.

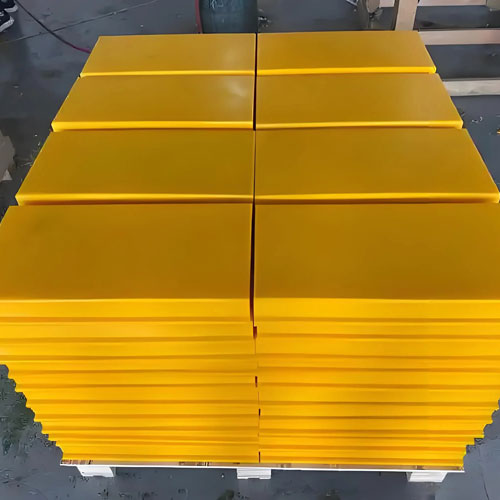

Thick Polyurethane Sheets, Boards & Blocks for Heavy-Duty Industrial Use

- Product Specifications

- Gallery

| Specification | Details |

| Material | High-quality Polyurethane (PU) |

| Hardness Range | Shore A 60–98 (custom available) |

| Thickness | 6–40 mm (customizable) |

| Width / Length | Custom sizes to fit machinery |

| Abrasion Resistance | Superior to rubber or plastic |

| Impact Resistance | Excellent for high-wear conditions |

| Temperature Resistance | Standard: -30°C to +80°C (custom options available) |

| Chemical Resistance | Resistant to oils, greases, and most industrial chemicals |

| Customization | Sizes, hardness, color, formulation |

| Production Volume | Small batch to high-volume OEM supply |

| Applications | Conveyors, mining, bulk material handling, machinery |

Polyurethane Sheet, Plate, Board and Blocks

| Product Type | Thickness | Rigidity | Typical Use | Applications / Benefits |

| PU Sheet | 1–6 mm | Flexible | Seals, liners | Conveyor skirting seals, protective liners, gaskets, pads, vibration isolation; thin and flexible for sealing and protective applications |

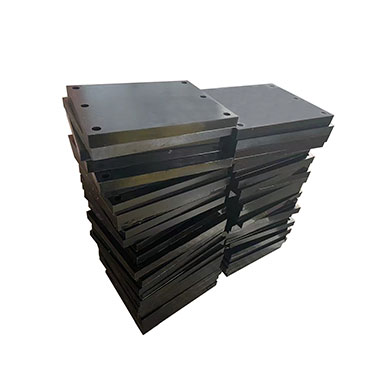

| PU Plate | 6–30 mm | Solid | Wear parts, machinable components | Wear plates, impact pads, blocks for machining; durable, abrasion-resistant, ideal for custom industrial parts |

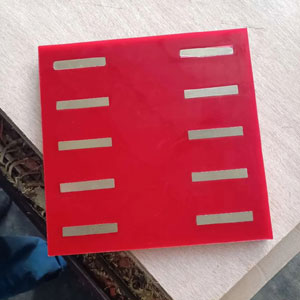

| PU Board | 10–40 mm | Rigid | Skirting boards, structural parts | Conveyor skirting boards, scraper blades, structural wear zones; rigid, maintains dimensional stability under load |

| Thick / Rigid Sheets | 6–40 mm | Semi-rigid to rigid | Sealing, lining | Industrial or conveyor protective applications; combines flexibility with durability |

| Polyurethane Wear Boards | 10–40 mm | Rigid | Skirting, structural wear | Conveyor guides and wear zones; abrasion-resistant and stable under load |

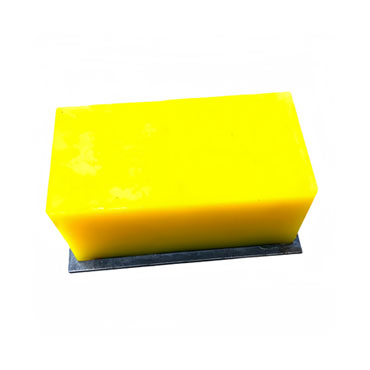

| Polyurethane Blocks / Slabs | Custom | Solid | Cutting, machining, fabrication | Custom wear parts or prototypes; large PU stock for machining or fabrication |

Related Products

Why Buy From Us

Our polyurethane plates tackle wear, abrasion, and impact challenges across industrial systems. From conveyor skirting boards to custom machined components, they protect equipment, improve efficiency, and minimize maintenance. Contact us to discuss custom sizes, hardness, and machining options for long-lasting wear protection.

Plates are solid and machinable (6–30 mm), sheets are thin and flexible (1–6 mm), and boards are thick, rigid formats (10–40 mm) for skirting or structural components.

Yes. They reduce noise, weight, and equipment wear while offering excellent abrasion and impact resistance.

Absolutely. PU plates can be CNC-cut, drilled, or fabricated to custom sizes, shapes, and hardness levels, ideal for OEM and replacement parts.

Thickness ranges from 6 mm to 40 mm; hardness typically 60 Shore A to 98 Shore A, customizable based on application requirements.

Mining, bulk material handling, conveyors, agriculture, recycling, and heavy manufacturing—anywhere abrasion and impact protection are critical.