Polyurethane Applications in the Steel Industry

Polyurethane components are essential in steel manufacturing for their toughness, elasticity, and abrasion resistance. PU rollers, pads, and coated components extend equipment life, reduce downtime, and improve operational efficiency. Their chemical resistance ensures smooth production even under harsh conditions.

Why Choose Polyurethane Solutions in the Steel Industry

- Durability & Longevity – PU rollers withstand high loads, abrasion, and chemical exposure, delivering long-lasting performance.

- Precision & Reliability – Polyurethane ensures accurate steel thickness, uniform coatings, and smooth processing, reducing defects.

- Cost Efficiency – Durable urethane lowers maintenance, roll replacement frequency, and production downtime.

- Custom Solutions – We offer tailored PU products to meet steel line requirements in hardness, size, and chemical resistance.

Polyurethane Products for Steel Production Line

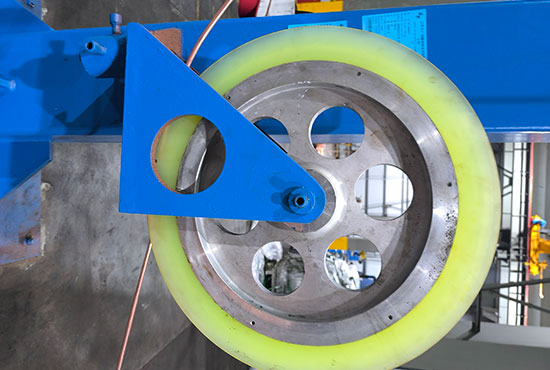

- PU Rollers – High-hardness tension rollers, guiding rollers, pinch rollers, and coated rollers maintain flatness and precision in cold rolling, galvanizing, color coating, and leveling lines. Their abrasion resistance, elasticity, and chemical durability reduce wear and extend service life.

- Coil Saddles & Pads – Protect steel coils during storage and transportation, preventing damage while supporting high loads.

- Seals & Liners – Polyurethane seals and liners safeguard equipment from abrasion, chemical exposure, and impact, ensuring stable production.

Industries & Scenarios in the Steel Industry

- Finishing Lines – PU rollers ensure even steel thickness, smooth coating, and precise positioning in cold rolling, galvanizing, color coating, and leveling operations.

- Transmission & Handling – PU unwinders, winders, and guiding components protect steel coils and maintain smooth operation in continuous production lines.

- Acid & Alkali Resistant Areas – Drying rollers and coated rollers resist hydrolysis and chemical attack, preventing contamination and preserving steel product quality.

Benefits for Steel Manufacturers

- Reduce equipment wear and maintenance costs with durable polyurethane rollers.

- Absorb vibration and impact, protecting sensitive machinery components.

- Improve steel product quality and consistency across finishing and coating processes.

- Customizable urethane solutions meet the specific needs of high-load, high-speed steel production lines.

Learn More About Polyurethane in Other Industries

Send Inquiry