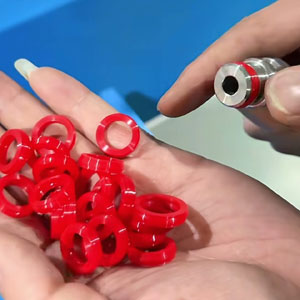

Polyurethane Ring

Polyurethane rings are essential industrial components where rubber wears prematurely and metal causes abrasion, noise, or damage. As a high-performance elastomer, PU combines wear resistance, elasticity, and load-bearing capability, making it ideal for rotating parts, conveyors, and heavy machinery.

Whether upgrading an existing design or sourcing replacement components, our PU rings offer long service life, dimensional stability, and reliable industrial performance.

Polyurethane Rings – Custom Molded Industrial PU Rings

Why Choose Polyurethane Rings Instead of Rubber or Plastic?

Polyurethane rings offer a balanced performance profile that traditional materials cannot match:

- Higher abrasion and tear resistance than rubber;

- Better load-bearing and resilience than most plastics;

- Reduced noise and vibration compared to metal components;

- Longer service life in harsh industrial environments;

- Customizable hardness, color, and material additives.

For many applications, switching to a polyurethane ring significantly reduces maintenance frequency and total operating cost.

Industrial Applications of Polyurethane Rings

- Conveyor rollers and belt systems;

- Bulk material handling equipment;

- Mining and quarry machinery;

- Cement and aggregate processing plants;

- Steel mills and metallurgical equipment;

- Automation and mechanical assemblies.

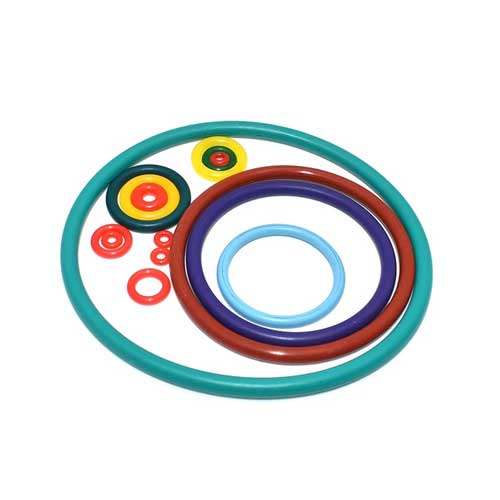

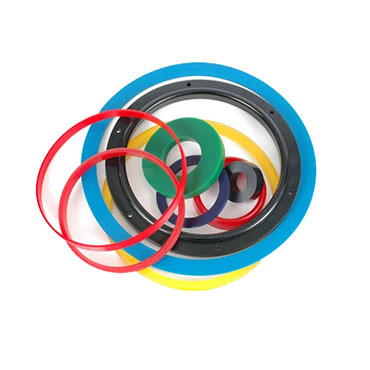

Polyurethane O-Rings for Industrial Sealing Solutions

- Product Specifications

- Gallery

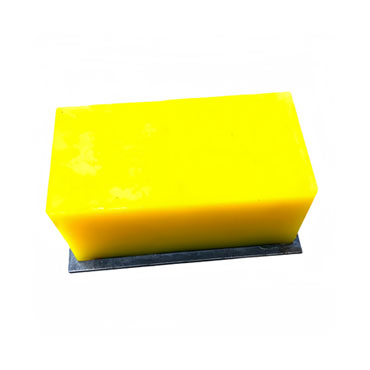

| Specification | Details |

| Material | Polyurethane (PU), cast or molded |

| Optional Formulations | Wear-resistant, oil-resistant, anti-static, hydrolysis-resistant |

| Dimensions | ID/OD/Thickness: Customizable; Tolerances per drawing |

| Hardness Range | Shore A 60–98 (Shore D available) |

| Mechanical Properties | High abrasion resistance, tear strength, elasticity, impact absorption |

| Load-Bearing Capacity | High, suitable for heavy-duty industrial applications |

| Operating Temperature | Standard: −30 °C to +80 °C (extended ranges available) |

| Chemical Resistance | Oils, greases, lubricants; custom materials available |

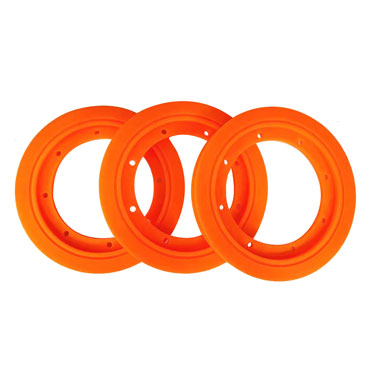

| Color Options | Standard: Yellow, red, black, blue; custom colors available |

| Production Volume | Small batch to high-volume OEM supply |

| Typical Applications | Wear rings, guide rings, support rings, spacer rings |

| Industry Use | Mining, cement, steel, conveying, bulk material handling |

| Customization Support | Drawings, samples, material and hardness consultation |

Polyurethane Rings vs Polyurethane O-Rings

| Product | Function | Applications | Customization |

| Polyurethane Ring | Wear, support, guidance, spacing | Rollers, conveyors, mechanical assemblies | Size, hardness, material |

| Polyurethane O-Ring | Sealing component | Hydraulic, pneumatic, fluid sealing | Size, hardness, material, OEM specifications |

Related Products

Custom Polyurethane Rings & Molded PU Ring Support

We offer industrial polyurethane rings using both cast and molded polyurethane processes to support small-batch and volume production.

- Cast and molded PU ring production;

- Custom Shore hardness and material formulations;

- Tight dimensional tolerances for OEM applications;

- Engineering consultation to meet mechanical, environmental, and service-life requirements.

Consider hardness, abrasion resistance, elasticity, and chemical resistance, depending on load, speed, temperature, and environment.

Provide a drawing or sample including ID, OD, thickness, tolerances, and desired hardness. We recommend the optimal formulation.

Yes. PU’s elasticity absorbs vibration, reducing noise and improving operational stability.

PU rings are for wear, support, and guidance, while PU O-rings are designed for sealing in hydraulic, pneumatic, or fluid systems.

Typically Shore A 60–98, with Shore D available on request, tailored to wear and load requirements.