Polyurethane Roller Sleeves

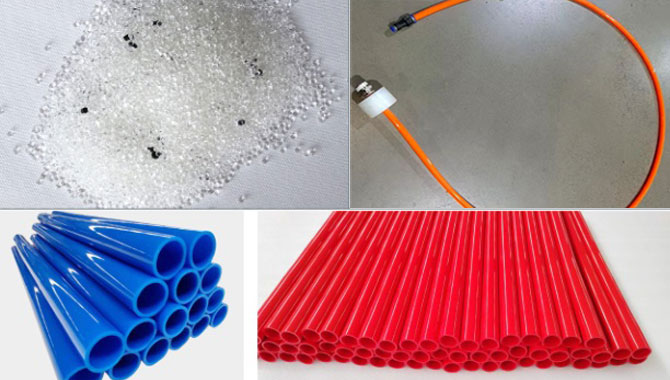

Polyurethane roller sleeves are tubular components made of polyurethane that are designed to fit over rollers. They are hollow, cylindrical structures and vary in size, thickness, and hardness depending on their intended use. These polyurethane sleeves are commonly used in various industrial and commercial applications.

Polyurethane Roller Sleeves and Roller Covers Supplier

Properties of Polyurethane Rollers Sleeves

- Good flexibility and excellent abrasion resistance.

- Light weight, easy to install with compressed air.

- Smooth inside and outside and many colors available.

- TPU material sheath is environmentally friendly.

Polyurethane Roller Sleeves Application

- Logistics Conveyor Roller shaft protective sleeve

- Electronic Manufacturing Production Line

- Automotive parts manufacturing

- Beverage bottling industry

- Woodworking industry

Custom Polyurethane Roller Sleeves Manufacturer

- Product Specifications

- Gallery

Dimensions of Polyurethane roller sleeves

- Inner Diameter: Precise inner diameter is crucial to ensure a proper fit on the roller. Polyurethane sleeves have a certain elongation rate, so usually the inner diameter of polyurethane sleeves is 1-2mm smaller than the outer diameter of steel rollers. Only after installing the TPU sheaths in this way can it be ensured that the polyurethane sleeve can be tightly fitted onto the conveyor roller.

- Outer Diameter: The outer diameter determines the effective surface area of the sleeve in contact with the conveyed materials. It is designed according to the specific requirements of the application, considering factors like the size of the products being transported and the required grip.

- Length: The length of roller sleeves can be cut as per your requirements, such as 1M, 2M, and 3M. Other lengths can be packaged into rolls for convenient transportation.

Physical Properties of Urethane Rollers Sleeves

- Hardness: The hardness of the polyurethane sleeves can be adjusted according to the application. For applications that require a strong grip, a harder shore hardness (e.g., 85 - 90 Shore A) may be chosen. For more delicate handling or shock - absorbing purposes, a softer hardness (e.g., 40 - 60 Shore A) is preferred.

- Tensile Strength: Polyurethane sleeves generally have high tensile strength, which ensures they do not break or tear under normal operating loads. Tensile strength values can range from 10 - 30 MPa depending on the specific formulation of the polyurethane.

- Elongation at Break: They also exhibit good elongation at break properties, typically ranging from 300% - 600%. This allows the sleeves to stretch slightly under stress without rupturing.

Chemical Properties of Urethane Rollers Sleeves

- Resistance to Oils and Greases: Polyurethane roller sleeves are highly resistant to oils and greases commonly found in industrial environments. This property ensures that the sleeves maintain their performance even when exposed to lubricants used in machinery.

- Chemical Agents: They can also withstand exposure to various chemical agents such as mild acids and alkalis. However, the level of resistance may vary depending on the concentration and type of chemicals. For example, they can tolerate diluted cleaning solutions used in food processing plants without degradation.

Working Temperature Range of Urethane Roller Sleeves

Polyurethane roller sleeves can operate within a relatively wide temperature range. They can withstand low temperatures down to - 20°C without becoming brittle and can handle high temperatures up to 80°C in many cases. In some specialized formulations, they can even endure higher temperatures for short periods.Performance Data of Thermoplastic Polyurethane Elastomers Material S1190

| Material properties | Test standard | Unit | Physical value |

| Density | ASTM D792 | g/cm³ | 1.2 |

| Shore Hardness | ASTM D2240 | Shore A | 92 |

| 100% Modulus | ASTM D412 | Mpa | 8.97 |

| 300% Modulus | ASTM D412 | Mpa | 29.38 |

| UV class | A method 48H | Class | 2.5 |

| Tensile strength | ASTM D412 | Mpa | 53.93 |

| Elongation at break | ASTM D412 | % | 413.34 |

| Tear strength | ASTM D642 | N/mm | 126.33 |

| Precipitation | Temperature 75 Humidity 75 24H | Light |

Performance Data of Polyester polyol/TDI series prepolymer Material

| Model | D3136 | D3145 | D3160 |

| NCO content / % | 3.6±0.1 | 4.5±0.2 | 6.0±0.2 |

| State of matter At 20℃ | White waxy solid | White waxy solid | White waxy solid |

| MOCA 100g prepolymer dosage /g | 10.5 | 13.2 | 17.2 |

| Viscosity(85℃)/ mpa * s | 1800 | 1200 | 900 |

| Mixing Temperature /℃(prepolymer/MOCA) | 85/120 | 80/120 | 75/120 |

| Gel time /min | 9 | 7.5 | 5 |

| Post vulcanization time (100℃)/h | 10 | 10 | 10 |

| Hardness ( shore A) | 85±1 | 91±1 | 96A±1 (54D) |

| 100% constant tensile stress /MPa | 4.2 | 6.7 | 11.5 |

| 300% constant tensile stress /MPa | 8.3 | 12.5 | 21.3 |

| Tensile strength /MPa | 48 | 52 | 55 |

| Elongation at break / % | 670 | 610 | 530 |

| Tear strength (right angle) /(KN/m) | 75 | 95 | 124 |

| Tear strength (pants type) /(KN/m) | 34 | 42 | 49 |

| Rebound /% | 39 | 32 | 33 |

| Density (25℃)/(g/cm) | 1.26 | 1.27 | 1.29 |

| wearing out by friction mm³ | 40 | 48 | 57 |

Related Products

Conveying Roller Protective Sleeve and TPU Sheath

In industrial logistics conveying applications, polyurethane roller sleeves and sheath are used to enhance roller performance. They enhance the grip of the rollers and ensure that products are transported smoothly through the conveyor system without slipping. They can also act as a cushion or shock absorber. The flexibility of polyurethane sleeves helps dampen vibrations and reduces stress on the rollers and the overall equipment. This extends the life of the machinery.

Our Polyurethane Roller Sleeves are made of TPU polyurethane. This material offers excellent abrasion resistance, high strength, and good flexibility, ensuring long - lasting performance in various applications.

Yes, we specialize in providing customized solutions. Whether it's the inner diameter, outer diameter, or length of the Polyurethane Sleeves, we can tailor them to meet your specific needs. Please provide us with the detailed dimensions and tolerances you require.

Put installation hardware into PU sleeves,like compressed air, Starting from one end of the roller, slowly and evenly slide the polyurethane sleeve onto the roller. You may need to apply gentle pressure to push the sleeve along the length of the roller. If the sleeve is too tight and not easy to slide, you can use a soft hammer or a sleeve installation tool to gently tap the sleeve into place. During this process, be careful not to damage the sleeve or the roller.

Our Polyurethane Sleeves can operate within a temperature range of - 20°C to 80°C. Some specialized formulations can even handle higher temperatures for short periods.

The lead time for custom polyurethane sleeves depends on the complexity of the design, quantity, and current production schedule. Generally, it can range from [12] days to [15] weeks. Our sales team will provide you with an accurate lead time estimate once we receive your detailed order requirements.