Polyurethane Rollers with Bearings

Polyurethane rollers with bearings are an indispensable part of many production facilities and conveying systems. It combines the abrasion resistance, high elasticity and good impact resistance of polyurethane, while the built-in bearings ensure that the rollers rotate smoothly, reducing frictional resistance and increasing the efficiency of the equipment.

Polyurethane Rollers with Bearings Suppliers

Properties of Polyurethane Rollers with Bearings

- Wear Resistance

- Elasticity and Shock Absorption

- Custom Design Flexibility

Manufacturing Process of Polyurethane Rollers with Bearings

- 1. Bearing Type Selection,

- 2. Polyurethane Material Preparation,

- 3. Metal Core Manufacturing (Optional),

- 4. Open Mold Casting or Closed Mold Injection Molding,

- 5. Curing, so that polyurethane bonds firmly to the bearing and core,

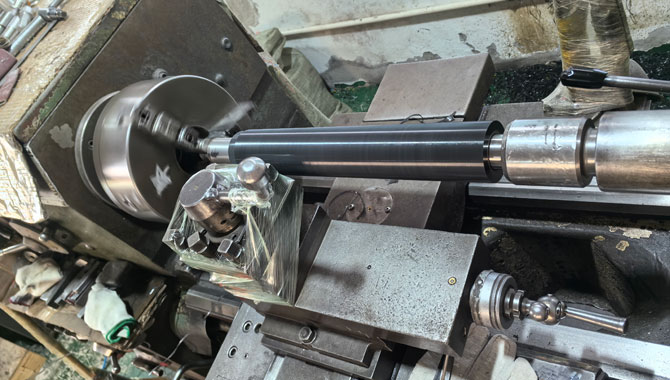

- 6. Machining and Surface Finishing, Assembly.

Custom Polyurethane Rollers with Bearings

- Product Specifications

- Gallery

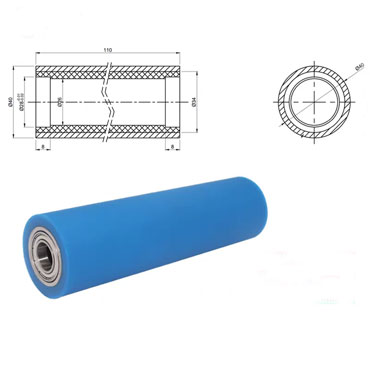

Specifications -Diameter and Length

- Diameter: The outer diameter of the polyurethane roller is a critical dimension. It determines the contact area with the conveyed material or other components in the system. Roller diameters can range from a few millimeters in small - scale precision applications to several hundred millimeters in large industrial conveyors. For example, a small - diameter polyurethane roller used in a printer might have a diameter of 20 mm, while a large roller in a steel mill conveyor could be 300 mm in diameter.

- Length: The length of the roller is also specified, as it affects the load - bearing capacity and the coverage area. It is measured from one end of the roller to the other. In a conveyor system, the length of the roller needs to be sufficient to support the width of the conveyed material. Roller lengths can vary from a few centimeters to several meters.

- Surface Finish: The surface finish of the polyurethane roller can be specified in terms of roughness or smoothness. A smooth surface finish, often measured in micrometers (μm) of surface roughness (e.g., Ra value), is desirable in applications where low friction and even contact are required, such as in food processing conveyors to prevent product sticking. A rougher surface might be specified in applications where better grip is needed, like in some textile or packaging machinery.

Polyurethane Material Specifications

- Hardness: Polyurethane hardness is usually measured on the Shore hardness scale, which can be either Shore A (for softer materials) or Shore D (for harder materials). The hardness of the polyurethane affects its mechanical properties, such as wear resistance and elasticity. For example, a roller used in a conveyor system for delicate items might have a Shore A hardness of 60, providing a relatively soft and gentle contact surface, while a roller for heavy - duty applications could have a Shore D hardness of 70 for greater durability.

- Tensile Strength - Tensile strength is the maximum stress that the polyurethane can withstand before breaking when pulled. It is specified in megapascals (MPa). A higher tensile strength indicates a more robust and durable polyurethane material. For instance, a high - quality polyurethane roller might have a tensile strength of 20 MPa, ensuring it can handle the mechanical stresses during operation.

- Elongation at Break - This specification measures the percentage of elongation that the polyurethane can undergo before breaking. It gives an indication of the material's flexibility and toughness. A polyurethane roller with a high elongation at break value, say 400%, can better withstand stretching and deformation during use without cracking.

- Bearing Type- The type of bearing used in the polyurethane roller is specified, such as deep - groove ball bearings, angular - contact ball bearings, or cylindrical roller bearings. Each bearing type has its own characteristics and is chosen based on the application requirements, such as the direction of the load, speed, and precision needed.

Performance Data of Thermoplastic Polyurethane Elastomers S1190

| Material properties | Test standard | Unit | Physical value |

| Density | ASTM D792 | g/cm³ | 1.2 |

| Shore Hardness | ASTM D2240 | Shore A | 92 |

| 100% Modulus | ASTM D412 | Mpa | 8.97 |

| 300% Modulus | ASTM D412 | Mpa | 29.38 |

| UV class | A method 48H | Class | 2.5 |

| Tensile strength | ASTM D412 | Mpa | 53.93 |

| Elongation at break | ASTM D412 | % | 413.34 |

| Tear strength | ASTM D642 | N/mm | 126.33 |

| Precipitation | Temperature 75 Humidity 75 24H | Light |

Polyester polyol/TDI series prepolymer

| Model | D3136 | D3145 | D3160 |

| NCO content / % | 3.6±0.1 | 4.5±0.2 | 6.0±0.2 |

| State of matter At 20℃ | White waxy solid | White waxy solid | White waxy solid |

| MOCA 100g prepolymer dosage /g | 10.5 | 13.2 | 17.2 |

| Viscosity(85℃)/ mpa * s | 1800 | 1200 | 900 |

| Mixing Temperature /℃(prepolymer/MOCA) | 85/120 | 80/120 | 75/120 |

| Gel time /min | 9 | 7.5 | 5 |

| Post vulcanization time (100℃)/h | 10 | 10 | 10 |

| Hardness ( shore A) | 85±1 | 91±1 | 96A±1 (54D) |

| 100% constant tensile stress /MPa | 4.2 | 6.7 | 11.5 |

| 300% constant tensile stress /MPa | 8.3 | 12.5 | 21.3 |

| Tensile strength /MPa | 48 | 52 | 55 |

| Elongation at break / % | 670 | 610 | 530 |

| Tear strength (right angle) /(KN/m) | 75 | 95 | 124 |

| Tear strength (pants type) /(KN/m) | 34 | 42 | 49 |

| Rebound /% | 39 | 32 | 33 |

| Density (25℃)/(g/cm) | 1.26 | 1.27 | 1.29 |

| wearing out by friction mm³ | 40 | 48 | 57 |

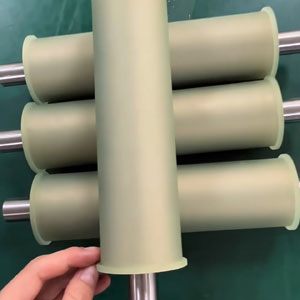

Lisen is able to offer customized solutions for polyurethane rolls with bearings according to the needs of different users. Whether it is special dimensions, hardness requirements or special designs for specific working environments, the individual needs of the user can be met.

Related Products

Polyurethane Roller with Bearings Manufacturers

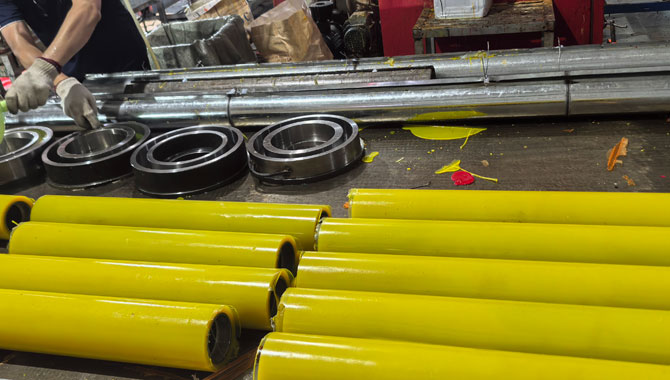

We provide cast urethane covered bearings and polyurethane molded bearing by different manufacturing process.

- 1). Open - Mold Casting: In open - mold casting, the prepared polyurethane mixture is poured into an open mold that contains the bearing (if the bearing is integrated during this stage) and the core (if present). The mold is designed to have the exact shape and dimensions of the desired roller. The polyurethane is allowed to flow around the bearing and core, filling all the voids. This method is suitable for producing rollers with relatively simple shapes and large sizes.

- 2). Closed - Mold Injection Molding: For more complex shapes and higher - precision requirements, closed - mold injection molding is used. The polyurethane mixture is injected under pressure into a closed mold cavity that already contains the bearing and core. The pressure ensures that the polyurethane fills the mold completely and conforms to the detailed geometry of the roller. This process can produce rollers with tight tolerances and smooth surface finishes.

Absolutely. We specialize in custom urethane products, whether it's size or shape, just provide us with a detailed drawing or specifications and we'll produce a urethane roller with bearings that meets your requirements.

We offer a wide range of surface treatment options, such as smooth surface treatment for scenarios requiring low friction, and special texture treatment that enhances the friction between the rollers and the contact material for different applications.

The service life of polyurethane rollers with bearings is affected by many factors, such as the environment, load size, operating frequency and so on. Under normal use and proper maintenance, they can maintain good performance for a long time. Our after-sales team can provide you with maintenance advice to extend the service life of your products.

These rollers are suitable for a variety of scenarios, such as food processing lines, logistics conveyor systems, printing machines, textile equipment, etc., which can meet the requirements of different industries on the performance of rollers.

The delivery time for customized polyurethane rollers with bearings depends on the complexity of the product and the order quantity. Generally speaking, from order confirmation to delivery, the time range is around [15] days to [18] weeks, and we will provide you with the exact delivery date after we take the order.