Polyurethane Round Belts

Polyurethane round belts are flexible and durable drive belts with a circular cross-section, made from polyurethane material. They feature a smooth surface, high strength, and excellent resistance to wear, chemicals, and abrasion. These properties make them ideal for environments where standard rubber or plastic belts fail. Industries commonly use them in power transmission, conveyor systems, and machinery that require efficient and reliable motion transfer.

Polyurethane Round Belt Suppliers and Manufacturers

Advantages of Polyurethane Round Drive Belts

- Abrasion Resistance and Durability

- Excellent flexibility and Elasticity

- Smooth or Rough Surface as Option

- Chemically resistant

Applications of Polyurethane Round Drive Belts

- Packaging and labeling machines

- Conveyor systems in light to medium-duty use

- Textile machines

- Office equipment (printers, copiers)

- Robotics and automation

- Food processing equipment (FDA belts)

Reinforced Polyurethane Round Belts Manufacturer

- Product Specifications

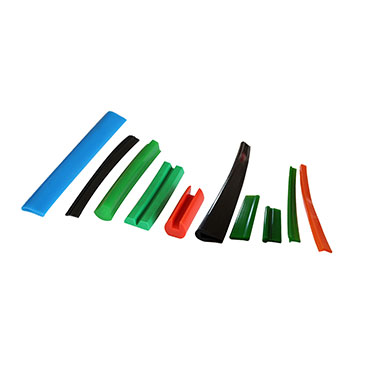

- Gallery

| Item | Specification / Description |

| Material | 100% Thermoplastic Polyurethane (TPU) |

| Hardness (Durometer) | 80A / 85A / 90A / 95A (Shore A) – depending on application |

| Standard Diameters | 2mm, 3mm, 4mm, 5mm, 6mm, 8mm, 10mm, 12mm, 15mm, etc. (custom sizes available) |

| Tolerance | ±0.05 mm to ±0.1 mm depending on diameter |

| Color Options | Orange, Green, Red, Clear, Blue, Yellow (custom colors available on request) |

| Reinforcement | Available with Polyester, Aramid (Kevlar), or Steel Cord Core (for high-strength needs) |

| Tensile Strength | Typically 30–90 N/mm² (varies with hardness and reinforcement) |

| Elongation at Break | 400%–600% |

| Working Temperature | -30°C to +80°C continuous (up to +100°C short-term) |

| Coefficient of Friction | Medium to high – depending on surface texture (smooth or rough finish available) |

| Weldability | Yes – heat-weldable for custom loop sizes |

| Oil & Chemical Resistance | Good resistance to oils, greases, and many industrial chemicals |

| Abrasion Resistance | Excellent – superior to rubber belts in wear-intensive environments |

| UV / Ozone Resistance | Good – resistant to aging and cracking from UV or ozone exposure |

| RoHS / REACH Compliance | Yes – meets most environmental and safety standards |

| Applications | Conveyors, packaging machines, sorters, printing, textile equipment, industrial automation |

Technical date of Polyurethane solid round belts

| Diameter mm | Length Mtr/Rolls | Minimum Pulley φ (mm) | Weight per meter (kg) | Working Load @ Percent Tension | |||

| 4% (N) | 6% (N) | 8% (N) | 10% (N) | ||||

| 2 | 400 | 16 | 0.004 | 0.9 | 1.3 | 1.8 | 2.2 |

| 2.5 | 400 | 19 | 0.007 | 0.9 | 1.3 | 1.8 | 2.2 |

| 3 | 400 | 21 | 0.009 | 2.2 | 3.1 | 4.4 | 5.3 |

| 3.5 | 400 | 25 | 0.013 | 2.2 | 3.1 | 4.4 | 5.3 |

| 4 | 200 | 32 | 0.016 | 3.6 | 5.3 | 7.1 | 8.5 |

| 5 | 200 | 40 | 0.025 | 5.3 | 8.0 | 10.7 | 13.3 |

| 6 | 200 | 48 | 0.036 | 7.6 | 11.6 | 15.6 | 19.1 |

| 7 | 100 | 51 | 0.049 | 8.5 | 12.9 | 17.3 | 21.4 |

| 8 | 100 | 64 | 0.063 | 13.3 | 20.5 | 27.1 | 33.8 |

| 9 | 100 | 76 | 0.080 | 19.1 | 29.4 | 39.1 | 48.5 |

| 10 | 50 | 80 | 0.099 | 20.9 | 32.5 | 43.1 | 53.4 |

| 12 | 30 | 105 | 0.142 | 33.8 | 52.5 | 69.8 | 85.8 |

| 15 | 30 | 120 | 0.221 | 47.6 | 72.9 | 97.4 | 120.1 |

| 18 | 30 | 127 | 0.318 | 52.9 | 81.8 | 109.0 | 134.3 |

| 20 | 30 | 152 | 0.393 | 78.7 | 117.9 | 157.0 | 193.5 |

Optional Customization for Polyurethane Round Drive Belts

- Hollow-core versions for lightweight needs or air-flow applications.

- Reinforced Core: With Polyester,Kevlar or steel cords for high-tension applications.

- Rough surface finish for improved grip.

- Precision-cut lengths or loop welding service.

- Anti-static or food-grade versions available.

Specification of Polyurethane Hollow Round Belts

| Size O.D. * I.D. | Length Mtrs/Roll | Min. Pulley Φ Diameter(mm) | Pull force (1%) kg. | Min. Pulley Φ Diameter(mm) | Pull force (1%) kg. | Weight kg/m |

| 5*2mm | 100 | 35 | 0.29 | 45 | 0.37 | 0.021 |

| 6*2mm | 100 | 45 | 0.49 | 55 | 0.63 | 0.032 |

| 8*3.5mm | 100 | 55 | 0.78 | 65 | 1.01 | 0.052 |

| 9.5*3.8mm | 50 | 65 | 1.10 | 75 | 1.41 | 0.086 |

| 10*4mm | 50 | 75 | 1.49 | 90 | 1.92 | 0.093 |

| 12*4.5mm | 50 | 85 | 1.88 | 100 | 2.42 | 0.135 |

| 15*5.2mm | 30 | 100 | 2.88 | 120 | 3.71 | 0.21 |

| 18*7.8mm | 30 | 180 | 8.95 | 0.259 | ||

| 20*7.8mm | 30 | 200 | 11.34 | 0.342 |

- Quick-Connector for hollow round belt, The Size of connector refers to the diameter of hollow belt, NOT the size of the hole in the belt.

- Connectors size : 5mm, 6mm, 8mm, 10mm, 12mm,15mm;

- Connector Material: Aluminum or Brass in available.

- Red Smooth or Green Rough Surface as options.

Related Products

Thermoplastic Polyurethane (TPU) Belt Manufacturer

We specialize in manufacturing high-performance TPU belts for power transmission and conveyor systems. Our belts offer superior abrasion resistance, flexibility, and chemical durability. Available in custom sizes and reinforced options, our thermoplastic polyurethane belts are ideal for industrial automation, packaging, and material handling applications.

Yes. Our extruded polyurethane belts are heat-weldable, allowing easy on-site joining into endless loops. We also provide belt welding kits or pre-welded belts upon request.

Hollow belts are lighter and easier to join with connectors but are suitable for light-load applications. Solid belts offer higher tensile strength and longer service life, ideal for heavy-duty or high-speed systems.

Our standard polyurethane round belts operate effectively from -30°C to +80°C, with short-term resistance up to 100°C, depending on the belt formulation.

Absolutely. We can produce FDA-compliant food-grade polyurethane belts or anti-static belts for electronics and dust-sensitive environments. Please contact us with your specific compliance needs.

Yes, we offer welding tools kits, included electric solder iron, belt clamp,cutters accessories for customers who prefer to weld belts on-site. We also provide instructions and technical support if needed.