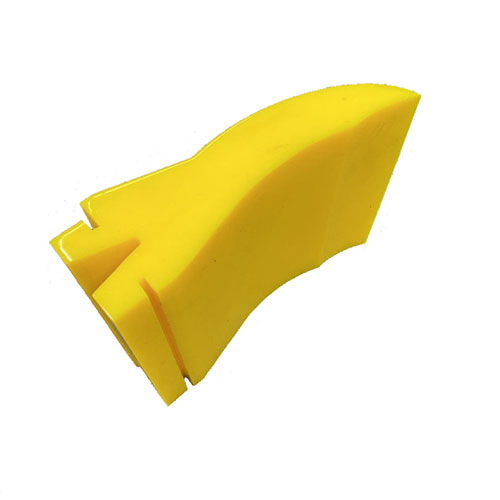

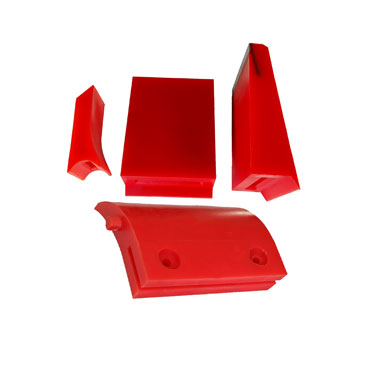

Polyurethane Scraper Blades

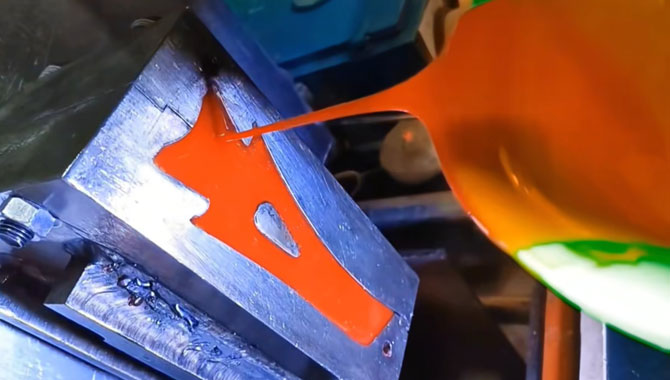

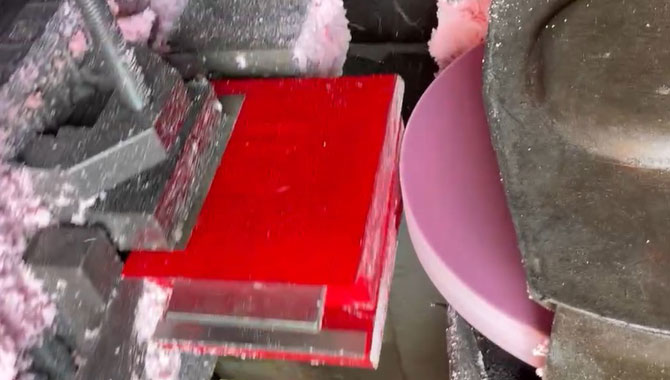

Polyurethane Scraper Blades (PU Scraper Blades) use durable polyurethane or urethane to remove carryback, dust, fines, and residue from conveyors and equipment. Available as replacement or custom-molded blades, they ensure exact fit, longer blade life, and efficient cleaning for industrial operations.

Polyurethane Scraper Blades – Durable, Wear-Resistant Industrial Replacement Blades

Why Choose Polyurethane Scraper Blades?

- Durable & Wear-Resistant: PU and urethane materials withstand abrasive materials and heavy-duty applications.

- Optimized Cleaning Efficiency: Precisely engineered to remove fines, dust, and carryback for smooth conveyor operation.

- Custom Fit & OEM Compatibility: Blades can be molded to your existing scraper drawings, belt width, and blade profile.

- Extended Service Life: Outlasts conventional rubber and steel alternatives, reducing downtime and maintenance frequency.

- Flexible Mounting Options: Bolt-on, clamp-on, or custom mounting solutions for all primary and secondary scraper systems.

Applications & Industries

- Mining & Quarrying: Efficient removal of ore, coal, and aggregates while reducing belt wear.

- Cement & Bulk Material Handling: Protects belts in high-load, abrasive environments.

- Industrial Conveyors: Manufacturing, packaging, and processing lines benefit from reduced downtime and improved cleanliness.

- OEM Conveyor Systems: Custom blades for retrofit or replacement on existing systems.

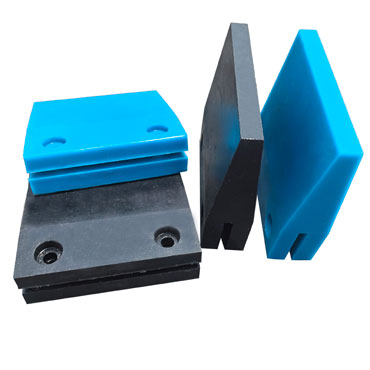

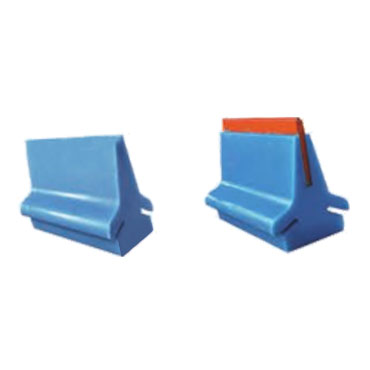

Custom and Replacement Polyurethane Scrapers Blades

- Product Specifications

- Gallery

| Specification | Options / Details | Notes |

| Material | Polyurethane (PU), Urethane | High abrasion resistance |

| Blade Type | Heavy-Duty, Light-Duty, Custom | Single-sided, double-sided |

| Length | 200–2000 mm | Customizable to match belt width |

| Thickness | 6–25 mm | Based on duty and application |

| Hardness | 70–95 Shore A | Flexibility vs abrasion resistance |

| Mounting | Bolt-on, Clamp-on | Compatible with primary/secondary scraper systems |

| Temperature | -40°C to 80°C | High-temperature grades available |

| Applications | Mining, Bulk Handling, Industrial Conveyors | Aggressive carryback removal |

| Replacement | Custom or OEM replacement blades | Exact fit guaranteed |

Related Products

Replacement Scraper Blade Mounting Options

- Bolt-on Mounting: Reliable and easy installation with standard bolts.

- Clamp-on Mounting: Fast installation without drilling, ideal for temporary setups.

- Custom Mounting: Tailored for non-standard frames, ensuring perfect contact and performance.

All mounting options work with primary and secondary scraper configurations to maintain precise wiping pressure and long service life.

Polyurethane scrape blades are used to remove carryback, dust, fines, or residue from conveyor belts, machinery, and material-handling systems. They improve cleanliness, reduce belt wear, and maintain smooth, efficient operation.

Yes. We offer fully custom polyurethane scraper blades, molded to match your existing belt width, blade profile, and mounting configuration for optimal fit and performance.

Please provide detailed drawings or sketches of your current scraper, including cross-sectional dimensions, blade length, width, thickness, profile shape, and mounting details. This ensures an exact match for your system.

Polyurethane blades generally last significantly longer than rubber and often outperform steel in abrasion resistance, flexibility, and overall wear life, reducing replacement frequency and downtime.

Yes, heavy-duty PU blades are designed for abrasive bulk materials, while softer grades are suitable for light-to-medium residue removal.