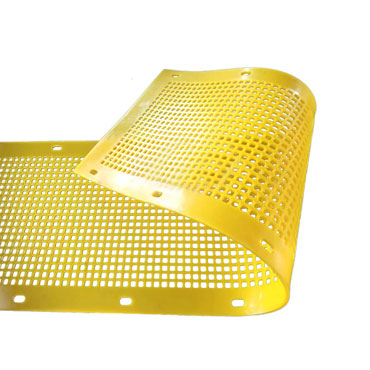

Polyurethane Screen Panels

Our Polyurethane Screen Panels deliver superior wear resistance and high screening efficiency. They ensure long service life in demanding industries such as mining, quarrying, coal processing, and aggregate production. Compared with traditional steel or rubber screens, polyurethane screen mesh reduce downtime and resist corrosion. They also provide cost-effective performance in both wet and dry screening applications.

High-Performance Polyurethane Screen Panels for Mining & Aggregate Screening

Why Choose Polyurethane Screen Panels?

- Outstanding Wear Resistance – High-strength polyurethane ensures long service life under abrasive conditions.

- Corrosion & Impact Resistant – Performs reliably in wet, high-impact screening environments.

- High Screening Efficiency – Precision-engineered apertures reduce clogging and increase throughput.

- Noise & Vibration Reduction – Quieter operation compared to steel wire mesh.

- Modular & Easy to Install – Compatible with most vibrating screens for quick replacement and maintenance.

- Cost-Effective – Lower maintenance frequency reduces overall screening costs.

Applications of Our Polyurethane Screening Panels

- Mining & Mineral Processing – Iron ore, copper, gold, coal, and other ores;

- Quarries & Aggregates – Sand, gravel, crushed stone screening;

- Cement & Asphalt Plants – Screening raw materials for production;

- Recycling Operations – Separating waste materials and aggregates;

- Custom Cast Polyurethane Screen Panels.

Polyurethane Screen Panels Manufacturers

- Product Specifications

- Gallery

Specifications of polyurethane screen panels

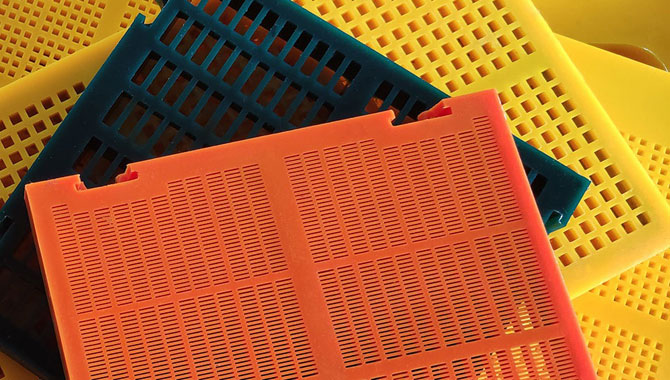

- Hole shapes and sizes: The holes are available in round, square, rectangular and trapezoidal shapes.

| Dia. of round screen holes (mm) | 0.075 | 0.1 | 0.15 | 0.2 | 0.25 | 0.3 | 0.5 | 0.6 | 0.7 | 0.86 | 1 | 1.18 | 1.4 | 2 | 4 |

| number of items | 200 | 140 | 100 | 70 | 60 | 50 | 35 | 30 | 25 | 20 | 18 | 16 | 14 | 10 | 5 |

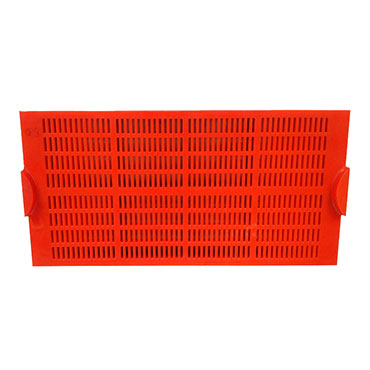

- External size: Include 305*305mm, 305*610mm, 610*610mm, 500*600mm, 600*600mm;There are options with single ears, double ears, and water - retaining edges. Special sizes can be customized according to different equipment and usage scenarios. The thickness generally ranges from 5 mm to 50 mm. Thicker panels are suitable for screening environments with high loads and impacts.

- Installation methods: include using rising nails, bolts, rail seats, slots, etc.

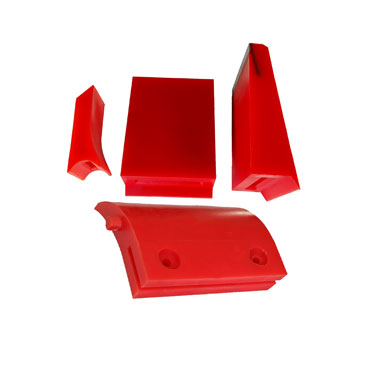

- Vibrating Screen Accessories:include Holding Bars, Installation Track Bars, Mesh Pins, PU Wedges, Side Holding Plates, etc.

Features of Urethane Screen Panels

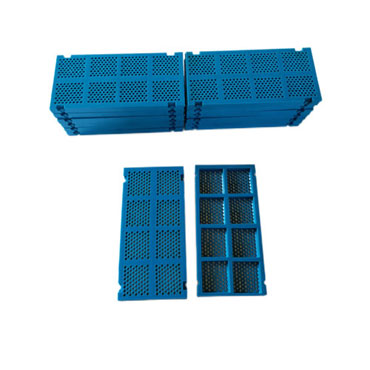

- Modular Polyurethane Screen Panels – Easy Replacement & High Wear Resistance;

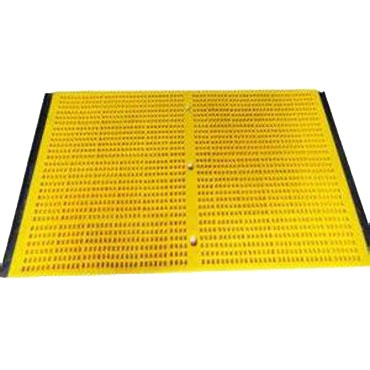

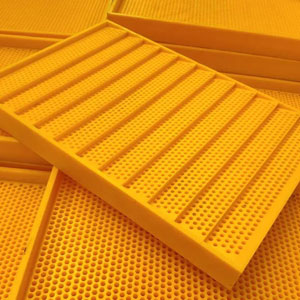

- PU Tensioned Screen Panels – For Vibrating & High-Frequency Screens;

- Fine Aperture Polyurethane Screens – Anti-Clogging Design for Precision Screening;

- Customized Polyurethane Screen Mesh – Tailored Aperture Size & Thickness;

Type of Polyurethane Screen Panels and PU Vibrating Screen Mesh

| Polyurethane Dewatering Screen Plate | Polyurethane relaxation screen | Polyurethane tensioning /flat screens |

| Dewatering screen panel, Pin Type Dewatering Screen Panel, PIPO Screen Panel, Wave Dewatering Screen Panel, WS85 Screen Panel, Dewatering Screen Panel, | Polyurethane relaxation screen, Round hole polyurethane relaxation screen, Flip Flow Screen, | Polyurethane relaxation screen with load bearing blind plate, Polyurethane flat screen with large holes, Polyurethane flat screens with impact beams, Polyurethane flat screen with small square holes, Polyurethane tensioning screen, Polyurethane tensioning screen with anti-clogging design, |

Related Products

Request a Quote for Custom Polyurethane Screen Panels

Looking for screen panels that fit your exact equipment and process needs? Our custom polyurethane screen panels are engineered to deliver superior wear resistance, high screening efficiency, and long service life — even in the toughest mining, quarrying, and aggregate environments.

With OEM/ODM manufacturing capabilities, we customize:

- Aperture sizes and shapes;

- Panel thickness and dimensions;

- Modular or tensioned screen designs;

- Material hardness for specific applications;

By choosing our factory-direct solutions, you gain reliable performance, reduced downtime, and cost-effective screening tailored to your operations.

Polyurethane screen panels are beneficial in various industries, including:

- Mining: For separating minerals and ores.

- Quarrying: For sorting aggregate materials.

- Coal Processing: For dewatering and classification.

- Construction: For screening sand and gravel.

- Recycling: For sorting recyclable materials.

Polyurethane screen panels offer several advantages over traditional metal screens, including:

- Enhanced wear resistance, leading to a longer service life.

- Improved screening efficiency, reducing material loss.

- Lower maintenance costs, due to reduced wear and tear.

- Noise reduction, contributing to a safer working environment.

- Customization options, allowing for tailored solutions to meet specific needs.

Selecting the appropriate polyurethane screen panel involves considering factors such as the material to be screened, desired aperture size, panel thickness, and the specific requirements of your application. Consulting with our technical team can help ensure you choose the optimal screen panel for your needs.

A polyurethane tensioning or flat screen is a type of screening media that is fixed onto a frame using tensioning devices. This design allows for effective separation of materials in various applications, including mining and aggregate processing. The tensioned structure ensures the screen remains taut, preventing sagging and maintaining screening efficiency.

A polyurethane dewatering screen plate is designed to efficiently separate water from materials in various industrial processes. Installation typically involves placing the screen plate onto the support frame of the vibrating screen machine, ensuring a secure fit to facilitate optimal performance.