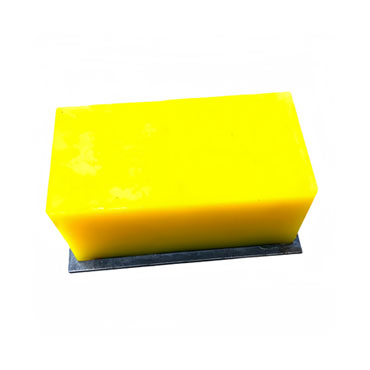

Polyurethane Shock Absorber

Polyurethane shock absorbers deliver high-performance vibration damping with excellent impact resistance, vibration control, and load protection. They combine the benefits of rubber and plastic, making them ideal for mechanical, automotive, and industrial equipment. These absorbers offer outstanding durability and resilience in demanding applications.

Shock Absorption & Energy Absorption Polyurethane Products

Application of Polyurethane Vibration Isolators

- Automotive - Suspension Systems.

- Industrial Equipment – Machinery.

- Aerospace - Landing Gear.

- Construction & Mining - Heavy-Duty Machinery.

Why Choose Our Polyurethane Shock Absorbers?

- Our shock absorbers are wear-resistant and provide long-term performance even under high-impact and high-vibration conditions. They also offer excellent elasticity and shock absorption properties, protecting your equipment and reducing downtime.

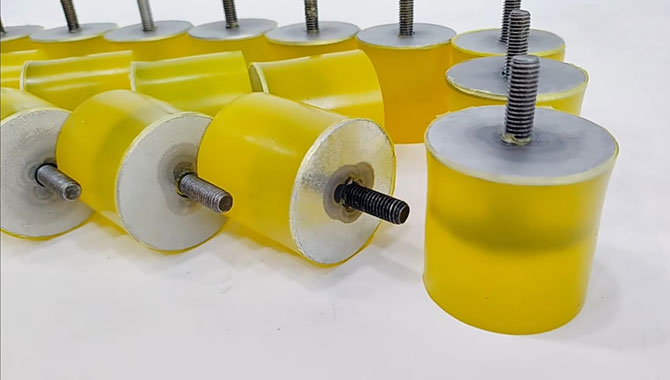

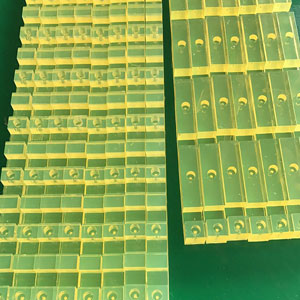

- We can custom-manufacture them according to your design drawings to meet your application needs, offering a variety of hardnesses, sizes, and colors.

- Our shock absorbers are durable and cost-effective, eliminating downtime caused by frequent replacements and minimizing long-term maintenance costs while maintaining high performance in diverse environments.

- Our polyurethane shock absorbers are suitable for a variety of industrial, automotive,machinery and aerospace applications, such as landing gear, suspension systems, and vibration isolation systems.

Vibration Control & Isolation Polyurethane Products

- Product Specifications

- Gallery

Why Polyurethane Over Other Materials?

- Better than Rubber: Polyurethane provides superior abrasion resistance and load-bearing capacity, outperforming traditional rubber shock absorbers.

- More Durable than Plastic: Polyurethane combines the elasticity of rubber with the strength of plastic, offering unmatched resilience and long-term performance.

- Chemical & Temperature Resistance: Handles exposure to harsh chemicals and extreme temperatures.

- Versatility: Works effectively across a range of industries and applications.

How Our Polyurethane Shock Absorbers Meet Your Specific Needs?

- Customizable Size & Shape: We offer custom-sized shock absorbers to fit your equipment perfectly, ensuring optimal performance.

- Hardness Options: Choose from a range of hardness levels to match your specific requirements for impact absorption and durability.

- Material Options: Standard polyurethane offers an excellent balance of performance and cost-effectiveness. High-performance polyurethane is ideal for extreme conditions, such as aerospace and heavy-duty machinery.

Technical Specifications of Polyurethane Shock Absorber

| Specification | Polyurethane Injection Molding | Cast Polyurethane Shock Absorbers |

| Usage | High-volume production of precise and complex shapes. | Custom shock absorbers requiring specific hardness and performance characteristics. |

| Process | Polyurethane injected into a mold under high pressure to form shapes and sizes. | Polyurethane poured into a mold and cured to form solid parts. |

| Advantages | High precision, repeatability, and ideal for detailed designs. | Greater customization for hardness, flexibility, and load-bearing capacity. |

| Hardness Range | From 40 Shore A to 95 Shore A | |

| Temperature Resistance | -30°C to 80°C (standard), up to 120°C for high-performance grades polyurethane material | |

| Custom Sizes | Available in various lengths, diameters, and configurations | |

Versatile polyurethane shock absorbers to improve the performance of your industrial applications

- Polyurethane shock absorbers play a crucial role in automotive suspension systems by effectively reducing road vibrations and ensuring a smoother ride. They also provide impact protection, safeguarding vehicle parts from sudden shocks during driving or while loading and unloading.

- In industrial machinery, polyurethane shock absorbers are vital for reducing vibration and shock. They help extend the service life of manufacturing equipment by minimizing wear and tear. Additionally, they contribute to smooth operation in material handling systems like conveyors and lifts, even under heavy loads.

- Polyurethane shock absorbers are essential in aerospace applications, particularly in landing gear systems. They provide necessary support in high-load situations and help absorb shock and vibrations during flight and landing, ensuring the protection of sensitive equipment.

- In construction and mining, polyurethane shock absorbers are used in heavy-duty machinery to resist shock and extreme vibrations. They help prevent damage caused by impacts, ensuring reliable performance and longevity in harsh environments.

Related Products

Polyurethane Shock Absorbers & Vibration Control Solutions

At Lisen, we specialize in manufacturing high-quality polyurethane shock absorbers and vibration control solutions designed to meet the demands of various industries. Our advanced polyurethane products are engineered to provide superior shock absorption, vibration damping, and noise reduction in automotive, industrial, aerospace, and heavy machinery applications.

Our polyurethane shock absorbers deliver exceptional durability and performance in reducing road vibrations, ensuring smooth rides in vehicles, protecting sensitive equipment in aerospace systems, and minimizing wear in manufacturing machinery. Whether you're in need of solutions for suspension systems, material handling, or high-load environments, our custom-made polyurethane products are tailored to meet your exact specifications, ensuring maximum efficiency and reliability.

With a commitment to quality and innovation, we offer a range of polyurethane shock absorbers and vibration control products that provide enhanced protection, longer lifespan, and greater performance across a wide variety of applications. Partner with us for durable, high-performance polyurethane solutions that improve your system's efficiency and longevity.

Yes, our high-performance polyurethane shock absorbers are engineered to withstand temperatures up to 120°C, making them suitable for a wide range of applications, including automotive and industrial machinery.

Absolutely! We offer customized sizes, hardness options, and shapes to meet the specific demands of your machinery or equipment.

Polyurethane shock absorbers are widely used in automotive, aerospace, industrial machinery, construction, and mining industries due to their high load-bearing capacity and durability.

With proper maintenance, our polyurethane shock absorbers can last for several years, even in high-impact environments, reducing overall maintenance costs.

Yes, polyurethane shock absorbers are perfect for conveyor systems, protecting the equipment from shocks and extending the system’s operational life.