Polyurethane Skirting

Polyurethane skirting is a high-performance conveyor belt sealing material made from abrasion-resistant PU. Compared with rubber skirting, polyurethane skirting offers longer wear life, reduced belt friction, improved dust control, and better spillage prevention in mining, aggregate, and bulk-handling conveyor systems.

Polyurethane Skirting | PU Conveyor Skirting & Skirt Boards for Dust Control

Why Choose Polyurethane Skirting?

- 3–5× Longer Wear Life: High-performance PU resists abrasion and tear far better than rubber skirting.

- Strong Sealing Performance: Our polyurethane sealing skirt maintains consistent pressure against the belt, improving dust suppression.

- Protects Your Conveyor Belt: Low-friction PU reduces belt wear and energy consumption.

- Compatible With All Conveyor Systems: Available as PU skirt board, urethane skirt board, dual seal polyurethane skirting, and custom OEM profiles.

- Lower Total Cost of Ownership: Less replacement, fewer shutdowns, reduced maintenance labor.

Industry Applications of PU Skirting

- Mining & Quarry

- Cement & Bulk Material Handling

- Ports & Terminals

- Recycling & Waste Processing

- Coal, Fertilizer, Chemical Plants

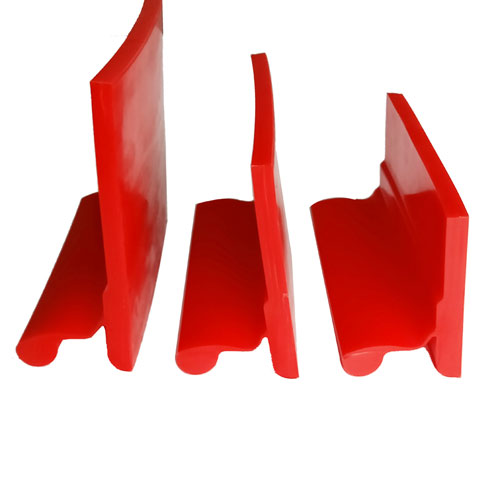

Dual-Seal Polyurethane Conveyor Belt Skirting

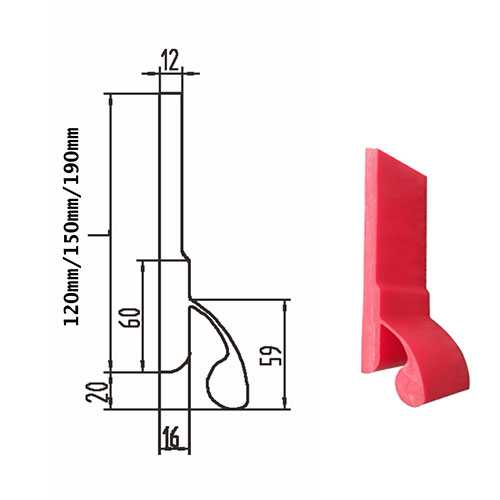

- Product Specifications

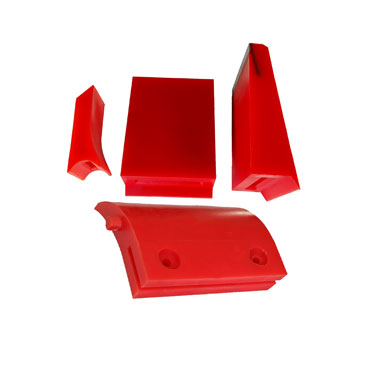

- Gallery

| Specification | Details / Range | Notes / Benefits |

| Material | Polyurethane (PU) / Urethane | High abrasion and tear resistance, long service life |

| Length | Customizable, 10M/15M/20M /30M per Rolls | Designed to fit standard conveyor profiles; OEM-compatible |

| Width | Customizable, typically 50–600 mm | Ensures effective sealing and minimal material spillage |

| Thickness | 6–25 mm | Thicker skirts provide longer wear life and better sealing |

| Design Type | Single-lip, Dual-lip / Dual-blade, Skirt Board | Choose according to dust suppression and material flow requirements |

| Temperature Range | -30°C to +80°C | Suitable for most industrial environments; optional high-temp PU available |

| Applications | Mining, quarry, cement, bulk handling, ports, recycling | Reduces dust, prevents spillage, extends conveyor belt life |

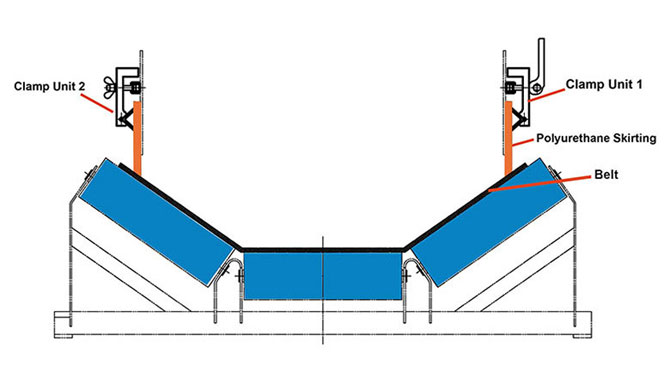

| Installation | Bolt-on or clamp system | Easy replacement and maintenance for minimal downtime |

Date Sheet of Polyurethane Skirting

| Description | Value |

| Color | Red, Orange, Green, Black,Blue as option |

| Hardness | 63±5, 70±5 , 85 Shore A |

| Density | 1.25 g/cm3 |

| Tensile; | 40 MPa |

| Elongation at Break | 660 % |

| Abrasion Loss | 40 mm3@10N |

| Angle Tear Strength(DIE C) | 57 KN/m |

| Trouser Tear Strength(DIE C) | 23 KN/m |

| Temperature Range | -30~70℃ |

| Rebound | 43% |

Technical Data of Dual Seal Polyurethane Rubber Skirt

| Double sealed belt skirts made of composite polyurethane and rubber | |

| A. Skirt Rubber: | |

| Polymer | NR/Synthetic |

| Specific Gravity | 1.26g/cm3 |

| Tensile Strength | 10 MPa |

| Hardness | 60 +/- 5 Shore A |

| Elongattion | 450% |

| Wear Loss @10N | 260mm3 |

| Temperature | - 20 ~80 ℃ |

| B. Polyurethane skirt board: | |

| Specific Gravity | 1.25 |

| Wear Loss @10N | 60 mm3 |

| Hardness | 88 ± 3 Shore A |

| Coefficient of Friction | (To rubber) < 2.2 |

Related Products

Key Benefits of Polyurethane Skirting

- Long-lasting wear resistance for heavy-duty conveyors

- Reduced spillage and dust emissions

- Protects belts and reduces downtime

- Compatible with standard and custom conveyor systems

High-performance Polyurethane Skirting (PU / Urethane) reduces dust, prevents spillage, and extends conveyor belt life. Request a Quote for Polyurethane Skirting, To get technical support, customization options, and durable conveyor solutions to improve your plant efficiency and reduce maintenance costs.

PU skirting seals conveyor belts, reduces spillage and dust, and protects belts from abrasion in heavy-duty material handling.

PU skirting offers higher wear resistance, longer service life, improved sealing, and better dust control than traditional rubber skirts.

Single-lip, dual-lip, dual-blade, skirt boards, sealing skirts, and dual-seal PU skirting for high-impact applications.

Yes, PU skirting can be tailored for length, width, thickness, hardness, and color to match your conveyor system specifications.

PU skirting can be installed using bolt-on or clamp systems for quick maintenance and minimal downtime.