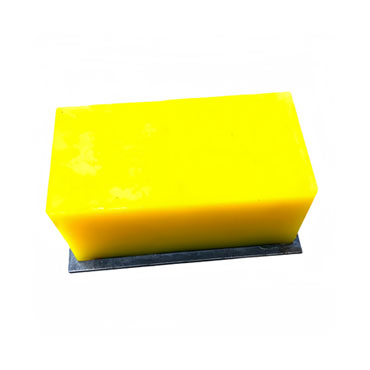

Polyurethane Spacer

Polyurethane spacers, also known as urethane spacers, provide exceptional durability, load resistance, and vibration control. They combine the elasticity of rubber with the wear resistance of plastics, giving them a unique advantage over traditional materials. Widely used in automotive suspensions, machinery isolation, and custom OEM projects, PU spacers deliver reliable performance and extended service life.

Polyurethane Spacers & Industrial Alignment Solutions

Why Choose Our Urethane Spacers?

- Customized Solutions – Tailored to size, hardness, and performance requirements.

- High Durability – Resistant to wear, abrasion, oil, and chemicals.

- Better Performance – Longer service life compared to rubber or plastic spacers.

- Versatile Applications – From automotive suspension to industrial vibration isolation.

- Direct Manufacturer Advantage – Competitive pricing and engineering support.

Polyurethane Spacer Application

- 1. Automotive & Suspension Systems.

- 2. Industrial Machinery.

- 3. Vibration and Shock Isolation in mechanical systems.

- 4. OEM Manufacturing & Custom Engineering.

- 5. Construction & Heavy-Duty Equipment.

Polyurethane Spacers for Automotive Suspension and Precision Tools

- Product Specifications

- Gallery

| Feature / Property | Polyurethane Spacers | Rubber Spacers | Plastic Spacers |

| Durability | Excellent wear & tear resistance, long service life | Prone to cracking & aging | Can become brittle under stress |

| Load Capacity | High load-bearing, maintains shape under compression | Medium, can deform under heavy loads | Low–medium, limited shock absorption |

| Abrasion Resistance | Outstanding – ideal for heavy-duty, high-friction use | Moderate | Poor – scratches and wears quickly |

| Temperature Range | -40°C to +80°C (up to +120°C with special formulations) | -20°C to +70°C | 0°C to +60°C |

| Chemical Resistance | Resistant to oils, grease, solvents, and fuels | Limited resistance | Weak resistance to oils/solvents |

| Flexibility | Good balance of flexibility & strength | High flexibility, but less strength | Low flexibility, prone to cracking |

| Applications | Automotive, machinery, vibration control, load leveling, OEM parts | General-purpose cushioning, light automotive | Low-load, non-critical assembly or insulation |

| Service Life | 3–5x longer than rubber or plastic | Shorter life, needs frequent replacement | Moderate but limited by brittleness |

Customization Polyurethane Spacers

- Tailored hardness, size, and shape according to application;

- Options for bonded metal inserts, washers, or bushings;

- Available in cast or molded polyurethane processes;

Related Products

Custom Polyurethane Spacers for Industrial & OEM Solutions

Our Custom Polyurethane Spacers are engineered to provide optimal performance in heavy-duty applications such as machinery assembly, automotive suspension, and vibration isolation. Offering superior abrasion resistance, load-bearing capacity, and chemical resistance, they are perfect for OEM solutions that demand durability and precision. Tailored to your specifications, our spacers ensure long-lasting suspension support in every application.

Polyurethane Spacers are custom-engineered components made from durable polyurethane, designed to provide precise spacing between parts in various applications. They are commonly used in machinery, automotive, industrial, and OEM solutions to absorb vibrations, isolate noise, and maintain proper alignment.

Polyurethane offers superior abrasion resistance, flexibility, and high load-bearing capacity, making it ideal for heavy-duty applications. It also provides better wear resistance, shock absorption, and chemical resistance compared to traditional materials like rubber and plastic.

Yes, Custom Polyurethane Spacers can be made to fit your specific dimensions and design requirements. Whether you need spacers for vibration isolation, load-bearing, or machinery alignment, we provide fully tailored solutions to meet your needs.

Polyurethane Spacers are commonly used in automotive, machinery, construction, industrial equipment, and OEM manufacturing. They help reduce wear and tear, improve performance, and offer long-term durability in environments that require heavy-duty components.

Polyurethane's elasticity and damping properties make it excellent for absorbing and isolating vibrations. Whether in machinery or automotive applications, Polyurethane Shock Spacers and Vibration Spacers effectively reduce noise and minimize the impact of vibrations.