Polyurethane Springs

Polyurethane springs offer a tough, lightweight, and cost-effective alternative to traditional metal springs. Designed for demanding industrial environments, they combine excellent load-bearing strength with superior wear resistance, impact absorption, and quiet operation.

At Lisen, we specialize in manufacturing custom polyurethane springs to meet your exact requirements. Whether you need standard dimensions or tailored solutions for heavy machinery, tooling, or OEM applications, our polyurethane molding expertise ensures dependable performance every time.

Polyurethane Springs – Durable, High-Performance Industrial Solutions

Advantage of our Polyurethane Springs

- Durability & reduced downtime;

- Noise & vibration control;

- Cost efficiency vs. metal or rubber alternatives;

- Customizable reliability options for specific applications.

Urethane Springs Application

- Stamping & Tooling – Punch presses, dies, and molds for reliable, repeatable force.

- Automotive & Transportation – Suspension systems, bumpers, seats, and vibration damping components.

- Mining & Heavy Equipment – Load-bearing pads and shock absorbers for crushers, excavators, and drilling rigs.

- Industrial Machinery – Press machines, conveyors, packaging lines, and general vibration control.

- OEM Solutions – Custom-designed polyurethane springs for integration into your products.

Custom Cast Polyurethane Springs

- Product Specifications

- Gallery

| Property | Value / Range | Notes / Options |

| Material | High-performance polyurethane elastomer springs | Custom formulations available |

| Hardness (Shore A/D) | 70A – 95A / 50D – 65D | Soft to rigid applications |

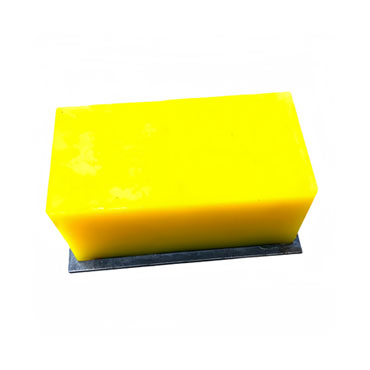

| Color | Red, yellow, green, blue, or custom | Standard: red & yellow |

| Load Capacity | Application-dependent | Designed for high compression loads |

| Deflection Range | 20% – 40% of free height | Ensures service life & durability |

| Tensile Strength | 25 – 55 MPa | High mechanical performance |

| Elongation at Break | 300% – 600% | High elasticity |

| Compression Set | <10% | Excellent resilience |

| Temperature Resistance | –40°C to +80°C (standard) / up to +120°C | Special formulations available |

| Chemical Resistance | Resistant to oils, greases, solvents, ozone, abrasion | Outperforms rubber & plastics |

| Wear Resistance | Excellent | Suited for high-cycle operations |

| Available Shapes | Cylindrical, rectangular, tube, bushings, pads, custom-molded | Based on design requirements |

| Common Applications | Press tooling, stamping dies, vibration damping, heavy machinery, automotive | Wide industrial use |

Related Products

Polyurethane Springs Manufacturer – Durable Urethane Springs for Industrial Applications

As a leading polyurethane products manufacturer, we supply Polyurethane Springs, Urethane Springs, and Compression Springs designed for high-performance industrial applications. Our springs deliver outstanding wear resistance, shock absorption, and reliability—ideal for dies, presses, and heavy machinery.

Looking for Polyurethane Springs or Urethane Compression Springs that meet your exact specifications? Contact us today for customized polyurethane molding solutions and bulk orders from China’s trusted manufacturer.

Polyurethane springs are elastic components molded from PU elastomer. They compress and rebound like metal or rubber springs but deliver superior abrasion resistance, energy absorption, and long fatigue life. They store and release mechanical energy through elastic deformation.

Choose polyurethane springs when you need: quieter operation, better wear and chemical resistance, high-cycle fatigue life, or safer failure modes (no sharp shards). Use them where shock/vibration damping and reduced maintenance are priorities. For extremely high static structural loads, steel may still be required.

We supply compression springs, tubular (tube) springs, die springs (for stamping/press tooling), mold springs, vibration/shock springs, and custom hollow or thick-walled spring shapes. All are available in a range of Shore hardnesses and geometries.

Provide: required free height, compressed height, inner/outer diameter (or cross-section), target load/deflection curve (N/mm or lbf/in), desired Shore hardness, operating temperature range, expected cycle count, and any chemical/environmental exposure. A drawing or sample speeds quoting.

Typical hardnesses range from ~70A to 95A (Shore A) for elastomer springs; specialty formulations go higher or into Shore D. Standard temperature range is about −40°C to +80°C; high-temp polyurethane compounds can operate up to ~120°C.