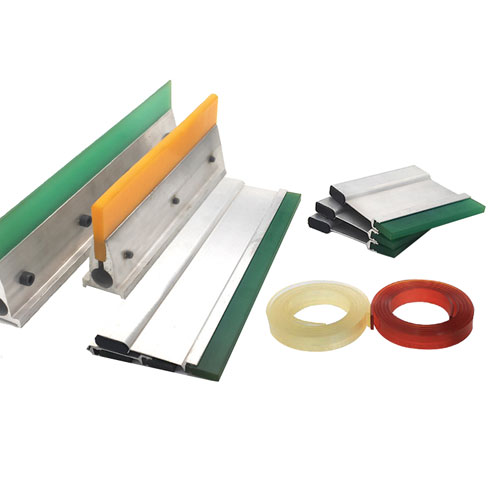

Polyurethane Squeegee

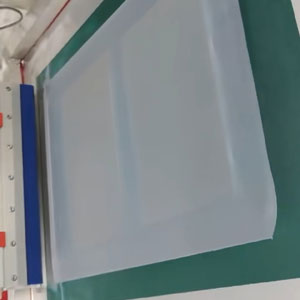

Polyurethane squeegee—also known as PU squeegee or urethane squeegee—features a flexible, high-performance polyurethane blade. It efficiently spreads, wipes, or removes inks, coatings, and liquids on flat surfaces.

Compared with rubber or plastic types, polyurethane squeegee blades offer superior wear resistance, chemical stability, and edge retention. Designed for durability and precision, each industrial PU squeegee ensures consistent performance in demanding screen printing and coating applications.

Wear-Resistant PU Scraper Blades for Industrial Coating & Printing

Why Choose Our Polyurethane Squeegee?

- High wear resistance;

- Excellent solvent and chemical resistance;

- Stable hardness and flexibility;

- Custom sizes, edge profiles available;

- Long service life reduces downtime and maintenance costs.

Industrial Application of Polyurethane Squeegee

- Screen Printing: Smooth ink transfer and precision printing;

- Industrial Coating / Laminating: Controlled spreading and scraping;

- Floor Cleaning & Maintenance: Efficiently removes liquids and debris from floors;

- Film & Vinyl Applications: Scratch-free, durable scraping.

Floor & Manual Scrapers Squeegee Blades Tools

- Product Specifications

- Gallery

Selection Guide of Polyurethane Squeegee Blade

| Item | PU-100 Series PU Squeegee Blade | PU-300 Series PU Squeegee Blade | PU-500 Series PU Squeegee Blade | PU-700 Series PU Squeegee Blade |

| Main Features | Hydrolysis resistance, acid/alkali resistance, high tear strength, good elastic recovery | Solvent resistance, high abrasion resistance, chemical stability in corrosive inks | High density, ultra-abrasion resistance, UV ink resistance, extremely low dimensional change | Ultra-high solvent resistance, strong corrosion resistance, controlled flexibility, anti-static performance |

| Main Applications | Textile printing, paste printing, wood substrates, decals | UV ink printing, CD/DVD, glass, ceramics, packaging, PCB | Precision PCB printing, solar panels, demolding screens | High-precision PCB printing, glass and ceramic printing with UV inks |

| Recommended Use | Standard printing processes using water-based systems requiring flexibility and moisture resistance | Medium-to-high intensity solvent or UV ink printing requiring wear resistance | High-precision screen printing processes requiring minimal expansion and long service life | Ultra-high precision and consistency-critical printing processes where electrostatic control is required |

Specification of Polyurethane Squeegee Blade

| Specification | Details |

| Material | High-performance polyurethane elastomer (PU) |

| Hardness Range | 55–95 Shore A ( tolerance +/-3 shore A) |

| Thickness Range | 2mm – 30 mm ( tolerance +/-0.2mm) |

| Width Options | 5mm – 500 mm ( tolerance +/-0.1mm) or customized per order |

| Length | 100mm – 4000mm, or custom cut lengths available |

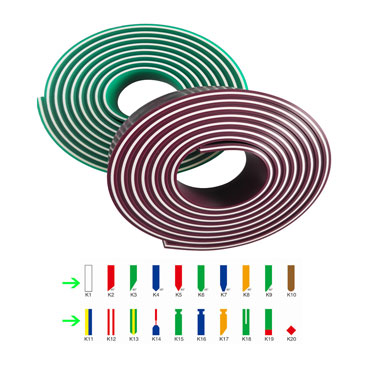

| Color Options | Red, Green, Yellow, Blue, Natural, or custom colors available |

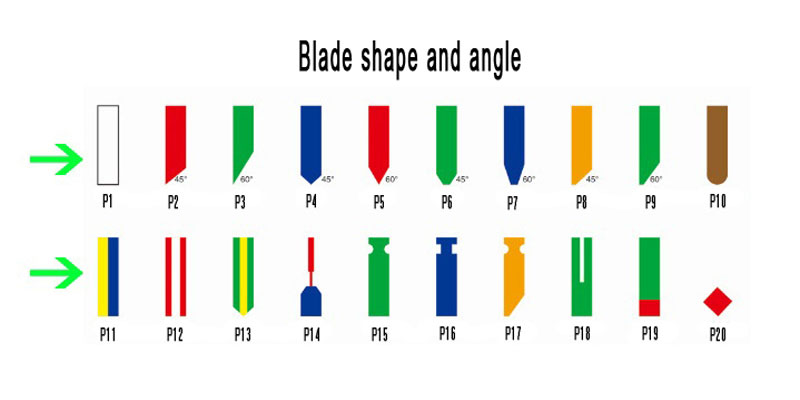

| Edge Profile Options | Square edge, beveled edge, round edge, single or double bevel – custom profiles available |

| Temperature Resistance | -30°C to +80°C (short-term up to 100°C) |

| Chemical Resistance | Excellent resistance to inks, solvents, oils, and cleaning chemicals |

| Tensile Strength | ≥ 30 MPa (depending on hardness) |

| Elongation at Break | 400–600% |

| Compression Set | ≤ 25% |

| Applications | Screen printing, coating, film and adhesive application, industrial wiping, and floor cleaning |

| Customization | Hardness, color, shape, and size can be tailored to OEM or application-specific needs |

| Manufacturing Process | Precision molded or cast polyurethane for consistent density and edge accuracy |

Optional Custom Polyurethane Squeegee Blade Features

- High-solvent or abrasion-resistant grades for aggressive chemical environments;

- Antistatic or conductive formulations for special applications;

- Precision-ground edges for uniform film or ink transfer;

- PU Squeegee for Solar/ Photo Voltaic (PV);

- PU Squeegee for Car decals.

Related Products

Custom Polyurethane Squeegee Blades Tailored to Your Needs

As a polyurethane squeegee manufacturer, we provide custom-engineered PU squeegee blades to match your machinery, surface type, and production conditions.Choose from:

- Multiple hardness options for controlled flexibility and pressure;

- Various edge profiles for different spreading or wiping needs;

- Solvent- and abrasion-resistant formulations to reduce maintenance and downtime.

Whether you need high-solvent-resistant PU squeegee blades for automated printing or hand tools for precision applications, our engineering team ensures every product enhances performance and reliability.

Polyurethane squeegees typically last longer, resist aggressive inks and solvents better, maintain sharper edges, and show less swelling during runs — improving print consistency and reducing replacement frequency.

Choose hardness by application: softer blades deposit more ink and conform better to uneven surfaces; harder blades (e.g., 70–80 Shore A) give finer detail and thinner deposits. Many printers use ~70A as a versatile choice; 80A for fine halftones or high-mesh work.

Polyurethane formulations can be optimized for water-based, solvent-based, and UV inks. Select a grade formulated for the specific solvent exposure (high-solvent grades for aggressive inks) to avoid swelling and premature wear.

Replacement depends on use, ink/solvent aggressiveness, and tolerance for print variation. For many industrial users, blades are inspected regularly and replaced when edges dull or print quality drops — ranges vary from days to months depending on intensity. Proper storage and occasional resharpening extend life.

Yes. Polyurethane floor squeegee blades are formulated for chemical resistance and durability in scrubbers and manual floor tools; they excel at removing oils and liquids on rough or oily surfaces and are offered in machine-specific sizes.