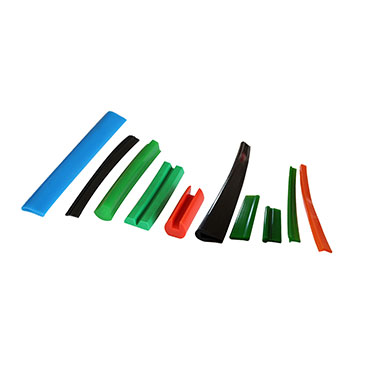

Polyurethane Strips

Polyurethane strips are made from durable, flexible, and elastic polyurethane. These strips are ideal for conveying systems, where they serve as guides, supports, belt edges, and seals. They are widely used in machinery manufacturing due to their chemical resistance, customizability, and cost-effectiveness.

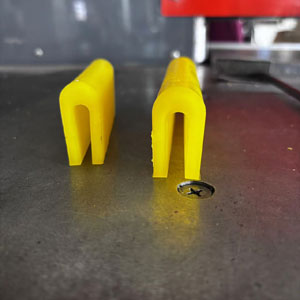

We produce polyurethane strips using extrusion, injection molding, and casting processes. These methods allow us to meet your exact size, hardness, profile, shape, and performance specifications.

Polyurethane Strips for Mechanical & Conveyor Applications

Why Choose Our Polyurethane Strips?

- Durable and Wear-Resistant

- Customizable Profiles and Sizes

- Cost-Efficient- Reducing downtime and replacement costs.

Function for Polyurethane Strips

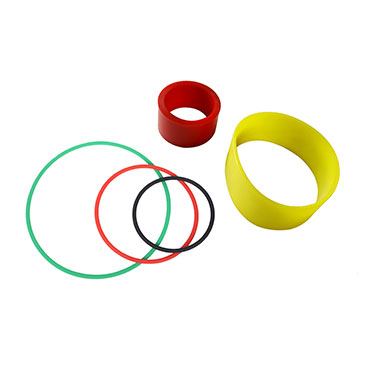

- As Seals & Gaskets: Provide effective sealing in mechanical components, preventing leakage and enhancing the efficiency of the system.

- Wear Strips: Protect machinery and equipment from damage caused by constant friction and mechanical stress.

- Guides & Supports: Offer precise guidance for moving parts, improving the accuracy and smoothness of mechanical processes.

- Conveyor Edge Seals: Protect conveyor belts by preventing the entry of dirt, moisture, and contaminants, ensuring cleaner and more efficient operation.

- Guide Strips: Direct the movement of materials along conveyor systems, maintaining alignment and preventing misfeeds.

- Wear and Tear Protection: Extend the life of conveyor components by reducing wear and tear from continuous operation.

Cast or Injection Polyurethane Wear Strips for Sealing Applications

- Product Specifications

- Gallery

| Specification | Extruded Polyurethane Strips | Injection Molded Polyurethane Strips | Cast Polyurethane Strips |

| Manufacturing Process | Polyurethane Extruded through a die to form continuous strips. | Polyurethane injected into molds under high pressure to form specific shapes. | Polyurethane cast into molds for custom shapes, profiles, and thicknesses. |

| Advantages | Cost-effective for mass production and standardized applications.- Consistency in shape and size.- Ideal for long, continuous lengths and larger volume orders. | Precise control over shape and size.- High-performance for high-stress and complex parts.- Ideal for small batches or when specific features or reinforcements are needed. | Excellent for applications requiring high load-bearing capacity and abrasion resistance.- Can be tailored to exact specifications for special applications.- Good for situations requiring high precision and uniformity in thickness. |

| Shape & Size Control | Standardized profiles with high consistency. | Precise shape and size control for specific designs. | Tailored shapes with precise thickness and uniformity. |

| Customization | Limited to standardized profiles; custom lengths are possible. | High customization for complex and detailed designs. | Fully customizable for shapes, profiles, thickness, and hardness. |

| Length Availability | Continuous lengths, customizable cut-to-size. | Typically in small batches, length may be customized per order. | Custom lengths (e.g., 1m, 2m, 3m), with thickness and hardness options. |

| Strength & Durability | Suitable for moderate stress applications; good wear resistance. | High-performance for high-stress, high-complexity parts. | Excellent for high-load, high-wear, and abrasion-resistant applications. |

| Load-Bearing Capacity | Moderate load-bearing capacity. | High load-bearing capacity, particularly for complex parts. | Very high load-bearing capacity and excellent abrasion resistance. |

| Production Volume | Suitable for high-volume, mass production. | Ideal for low to medium volume with high detail. | Typically for low to medium volume, high-performance or specialized orders. |

| Surface Finish | Smooth, even surface. | Smooth, precise surface finish depending on mold quality. | Customizable surface finish; typically very smooth and uniform. |

| Customization Options | Custom lengths and thicknesses. | Custom shapes, reinforcement, and additional features (e.g., ribs). | Fully customizable in terms of shape, profile, thickness, and hardness. |

| Cost-Effectiveness | Most cost-effective for standard profiles and high-volume production. | Higher cost due to precision and small batch production. | Higher cost for custom and specialized applications. |

| Applications | Material handling, conveyors, guides, wear strips. | Precision seals, engineering parts, small batch production. | High-performance industrial settings, wear-resistant parts, custom seals. |

How to choose the right production process for your application?

1. Extruded Polyurethane Strips:- Best for mass production, standardized sizes, and cost-efficiency.

- Ideal for general industrial applications like material handling, conveyors, and wear strips.

- Offers precision and complex shapes, making them suitable for small batches and detailed applications like seals and engineering components.

- Highly customizable, best for high-performance applications requiring precision, load-bearing, and abrasion resistance.

- Commonly used for high-stress, wear-resistant parts in industrial settings.

Related Products

Custom Polyurethane Wear Strips from Lisen

At Lisen, we specialize in providing custom polyurethane wear strips tailored to your specific needs. Whether you require extruded, injection-molded, or cast polyurethane wear strips, we offer flexible solutions for any industrial application.

Our diverse manufacturing processes ensure that we can meet different performance requirements, from high-volume, standardized applications to precision, high-stress environments. With the ability to customize size, shape, and material hardness, we provide durable and cost-effective wear strips that improve the efficiency and longevity of your systems.

Contact us today to discuss your unique application needs and get a custom solution tailored to your your wear strip needs!

Polyurethane strips offer better wear resistance, higher tensile strength, and are more abrasion-resistant than rubber strips. They are ideal for applications requiring longer service life and higher load-bearing capacity.

Yes, we offer FDA-compliant polyurethane strips suitable for food processing and packaging applications. These strips are safe for use in environments where direct contact with food is required.

Yes, polyurethane strips are highly resistant to a wide range of chemicals, oils, greases, and solvents, making them suitable for use in harsh industrial environments, including automotive, food processing, and pharmaceutical industries.

Polyurethane strips are highly durable and can last significantly longer than rubber or plastic materials due to their excellent wear resistance. Their lifespan depends on the application, load, and environmental factors but generally provides extended service life.

Polyurethane strips are widely used in sealing, wear protection, and guiding applications. They are ideal for machinery, conveyor systems, material handling, and industrial sealing, offering durability, flexibility, and high wear resistance.