Polyurethane Turnover Box

Our polyurethane (PU) turnover boxes serve the photovoltaic (PV) and polysilicon industries with a high-performance alternative to HDPE, PP, ABS, and metal boxes. They protect fragile silicon ingots, rods, wafers, and recycled materials during every handling step. Each PU box delivers strong impact resistance, stable chemical performance, reliable anti-static protection, and precise dimensions. These features keep materials intact and support smooth operation on automated production lines.

Polyurethane Turnover Boxes for Photovoltaic Silicon Ingot & Wafer Manufacturing

Pain Points and Demands of the Photovoltaic and Polysilicon Industries

- Photovoltaic materials: Glass and wafers are fragile and high-value; improper handling causes breakage and losses.

- Polysilicon: Heavy, acidic/alkaline processed raw materials increase handling difficulty.

- Static electricity hazards: Silicon powder attracts dust, complicates cleaning, and may trigger micro-dust explosions.

- Deficiencies of traditional containers: Wooden or plastic boxes crack easily and corrode; metal boxes are heavy, scratch materials, and increase labor costs.

- These pain points reduce efficiency, increase material loss, and drive up total costs.

Why Choose Our Polyurethane Turnover Boxes

- Industrial-grade PU molding: Large one-piece casting; shock-absorbing, acid- and stain-resistant, suitable for cleanroom use.

- Superior durability: High impact and abrasion resistance; edges and corners reinforced to minimize breakage.

- Chemical and corrosion resistance: Protects silicon materials from acids, alkalis, cutting fluids, and solvents.

- Lightweight and reusable: 50% lighter than metal, reducing labor and logistics costs.

- Anti-static option: Prevents electrostatic damage in ESD-sensitive wafers and components.

- Automated production compatible: Supports AGVs, conveyors, and robotic handling with precise dimensions and stability.

- Fully customizable: Sizes, hardness, internal cavities, anti-static properties, and inserts tailored to your factory needs. PU Ultra-high hardness material, scratch-resistant, smooth, cleanroom-compliant surface, dimensional tolerance ±1mm, long service life under repeated stress.

Customized PU Turnover Box Solutions for Photovoltaic and Polysilicon Industries

- Product Specifications

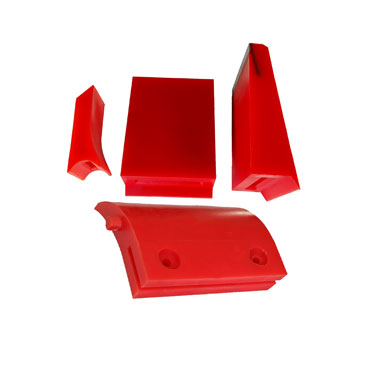

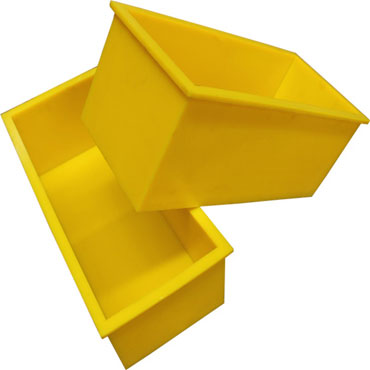

- Gallery

Polyurethane Turnover Box Applications

- Ingot / rod transport: Protect fragile silicon materials during production transfer.

- Wafer slicing & polishing: Compatible with automation and cleanroom protocols.

- Silicon material recycling: Chemical-resistant for scrap or slurry handling.

- Automated logistics: AGV and robotic line-friendly for high-frequency internal handling.

Polyurethane Turnover Box – Technical Specifications

| Feature | Specification | Benefit |

| Hardness | 90–98 Shore A / 65–70 Shore D | Adjustable cushioning vs. rigidity |

| Density | 1.10–1.25 g/cm³ | Stable for heavy loads |

| Tensile Strength | 15–45 MPa / 60 MPa | High load-bearing |

| Tear Strength | 35–80 kN/m / 125 N/mm | Protects edges and corners |

| Compression Set | ≤10% / 20–25% | Maintains shape under repeated load |

| Abrasion Resistance | ≤25–40 mm³ | 5–10× better than HDPE/PP |

| Temperature Resistance | -40°C ~ +120°C | Safe in cold & humid environments |

| Anti-Static / ESD | 10⁶–10⁹ Ω | Protects wafers in cleanroom environments |

| Load Capacity | Up to 150 kg | Supports ingots, wafers, and rods |

| Custom Dimensions | Available | Length, width, height, cavity shapes |

Custom Polyurethane Turnover Boxes Solutions

- Silicon wafer turnover boxes and baskets: Shockproof and anti-static for cleanrooms.

- Silicon rod transport carts: Ready for automated or manual cleanroom use.

- Photovoltaic module boxes: Large one-piece molding, compatible with 182/210mm modules.

- Corrosion-resistant sealed boxes: Acid/alkali resistant and leak-proof for hazardous materials.

- Heavy-duty material boxes: Reinforced to support 1–3 tons of silicon materials.

Case Studies & Application Value

- LONGi & WACKER adoption: Container loss costs reduced by up to 30%.

- Material loss reduction: Optimized handling lowers silicon material loss by ~33%.

- Minimized contamination: PU surface prevents contact with metal or old box surfaces.

- Automation-ready: Integrates seamlessly with conveyors, AGVs, and robotic lines, improving efficiency and safety.

Related Products

PU Turnover Boxes for Midstream PV and Polysilicon Enterprises

- Polycrystalline silicon ingot / monocrystalline rod manufacturers: Require impact- and abrasion-resistant boxes for safe handling of fragile silicon materials.

- Wafer manufacturing plants (cutting, grinding, polishing, cleaning, packaging): Need lightweight, anti-static, and precision-sized boxes compatible with AGVs, conveyors, and robotic lines.

- Silicon material recycling companies: Handle broken wafers, silicon slurry, or scraps, demanding chemically resistant and wear-resistant containers.

- These customers require containers that are protective, reusable, compatible with automation, and resistant to chemicals and abrasion.

Suitable for internal handling of silicon ingots, polycrystalline rods, polysilicon chunks, granules, scrap, and recycled silicon materials. Not intended for long-distance shipping.

Yes. Molded with precise dimensions and durable structure, they work efficiently with AGVs, conveyors, and robotic systems.

Yes. They resist chemical corrosion from polysilicon, silicon powders, cutting fluids, or cleaning solvents, protecting both containers and materials.

Yes. Shock absorption, cushioning, and abrasion protection minimize chipping, breakage, and edge damage during internal handling and stacking.

Absolutely. Internal dimensions, wall thickness, hardness, inserts, and anti-static treatments can be tailored to factory processes or special silicon material needs.