Polyurethane Wheel Chocks

Polyurethane wheel chocks securely restrain trucks, forklifts, aircraft, and industrial vehicles during parking, loading, unloading, and maintenance. Engineered from high-performance PU, they offer superior wear resistance, high load capacity, and long-term dimensional stability, outperforming rubber and plastic alternatives in demanding industrial environments.

Polyurethane Wheel Chocks – Durable, Non-Slip Vehicle Restraints

Why Choose Polyurethane Wheel Chocks?

- Combines rubber elasticity with plastic strength for reliable vehicle restraint;

- Non-slip traction on concrete, asphalt, and steel surfaces;

- Resists wear, deformation, and cracking;

- Weather, UV, and chemical resistant for indoor and outdoor use;

- Lightweight, reusable, and easy to handle;

- Customizable in size, hardness, color, and branding.

Applications of Urethane Wheel Chocks

- Logistics yards, loading docks and Fleet parking areas;

- Forklift and material handling operations;

- Aviation ground handling and aircraft parking;

- Industrial plants and manufacturing facilities;

Urethane Wheel Chocks for Trucks, Forklifts & Aircraft

- Product Specifications

- Gallery

| Specification | Details |

| Product Type | Molded Polyurethane (PU) Wheel Chock |

| Material | High-performance cast or molded PU |

| Density | 0.85 g/cm³ |

| Hardness Range | Shore A 85–95 (custom available) |

| Load Capacity | Light to heavy-duty (application-dependent) |

| Surface | Smooth or molded non-slip traction |

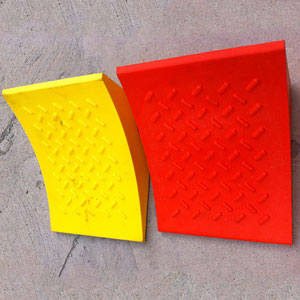

| Color Options | High-visibility yellow, orange, red, or custom |

| Temperature Range | −30 °C to +80 °C (custom available) |

| Chemical Resistance | Resistant to oils, fuels, greases, and most chemicals |

| Weather Resistance | UV-stable, moisture-resistant |

| Abrasion Resistance | Superior to rubber wheel chocks |

| Impact Resistance | Excellent shock absorption |

| Dimensional Stability | Maintains shape under continuous load |

| Manufacturing Method | Cast or molded polyurethane |

| Customization | Size, hardness, color, logo, OEM branding |

| Typical Vehicles | Trucks, trailers, forklifts, aircraft |

| Applications | Loading docks, fleet yards, warehouses, airports |

Specification of Car Wheel Chocks

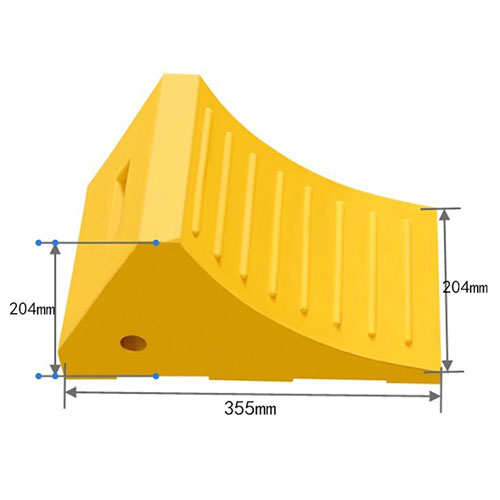

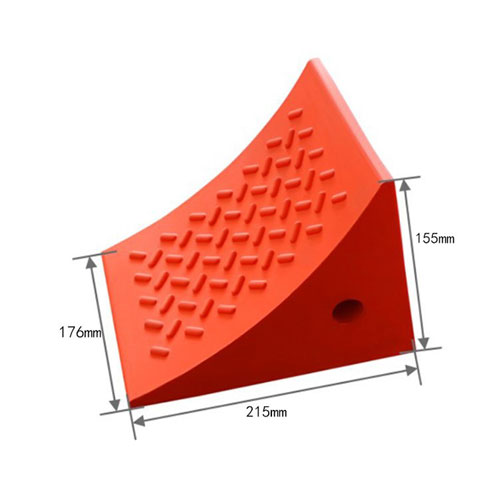

| Part no. | Size(L*W*H) | Max. Dia. of wheel tyres | Max. loadcapacity | weight |

| PUWC001 | 200-174*147mm | 650mm | 5t | 0.9kg |

| PUWC002 | 215-176-155mm | 560mm | 10t | 1.2Kg |

| PUWC003 | 280-200-200mm | 816mm | 20t | 1.7Kg |

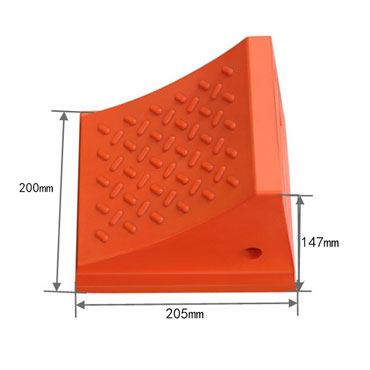

| PUWC004 | 205-200-147mm | 900mm | 20t | 1.8kg |

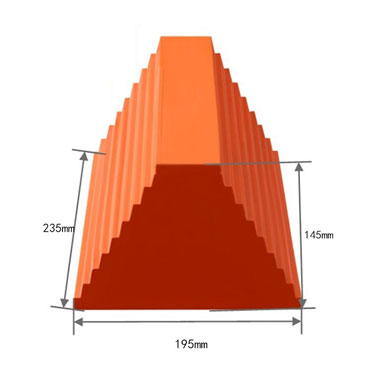

| PUWC005 | 235-195-145mm | 570mm | 20t | 1.8kg |

| PUWC006 | 287-224-206mm | 890mm | 30t | 2.6kg |

| PUWC007 | 355-204-204mm | 580mm | 30t | 2.7kg |

| PUWC008 | 332-215-193mm | 1400mm | 40t | 3.5kg |

| PUWC009 | 380-300-280mm | 1020mm | 60t | 6Kg |

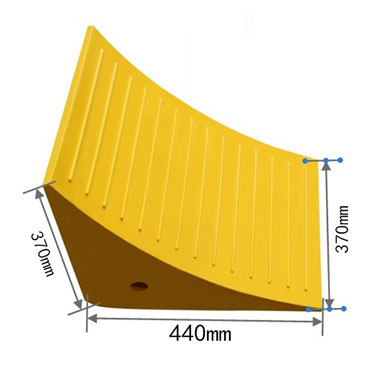

| PUWC010 | 440-370-370mm | 1474mm | 120t | 9Kg |

| PUWC011 | 526-278-310mm | 1120mm | 135t | 10Kg |

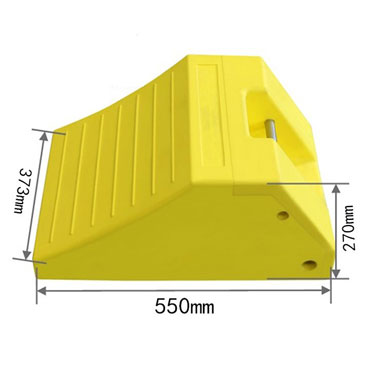

| PUWC012 | 550-373-270mm | 3600mm | 250t | 17.7kg |

| PUWC013 | 610-210-165mm | * | * | 8Kg |

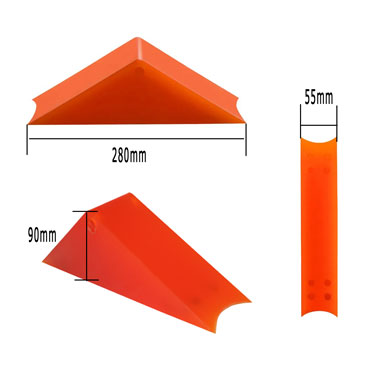

| PUWC014 | 280-55-90mm | * | * | 0.9kg |

| PUWC015 | 620-360-400mm | 4000mm | 400t | 14kg |

| PUWC016 | 655-320-340mm | 4000mm | 400t | 13Kg |

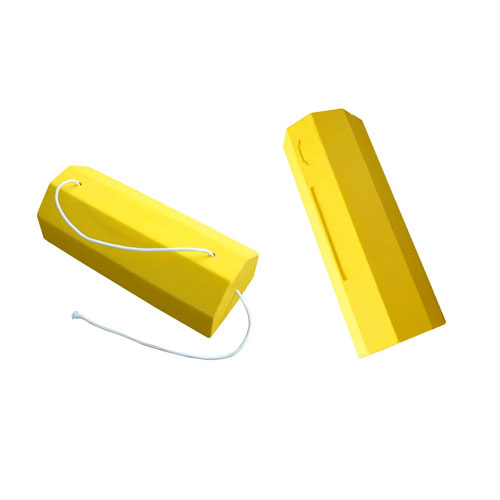

Specification of Aircraft Wheel Chocks

| Part No. | Size(L*W*H) | weight |

| PUAWC001 | 765*210*110mm | 5.8kg |

| PUAWC002 | 625*218*135mm | 5.8kg |

| PUAWC003 | 615*210*165mm | 5.8kg |

| PUAWC004 | 600*210-120mm | 6KG |

| PUAWC005 | 560*230*170mm | 6.6kg |

Related Products

Why Buy From Us?

We provide custom-molded polyurethane safety and wear products for industrial customers worldwide. Our urethane wheel chocks are designed to meet real-world operational demands—reducing safety risks, minimizing replacement frequency, and lowering long-term costs.

From standard industrial wheel chocks to custom PU wheel restraint solutions, we support OEMs, distributors, and end users with consistent quality and reliable supply.

Contact us today to discuss your application, load requirements, or custom polyurethane wheel chock specifications.

Select based on vehicle weight, tire size, operating surface, and application (truck, forklift, aircraft). Ensure compliance with workplace safety standards.

Yes. PU wheel chocks resist UV, temperature extremes, oils, fuels, and moisture, making them ideal for outdoor yards, docks, and airport aprons.

Yes. Many feature molded or textured surfaces for maximum grip on concrete, asphalt, and steel surfaces.

Wheel chocks are typically made using cast or molded polyurethane. This process produces durable, solid parts with uniform density, excellent load capacity, and long‑term performance in heavy‑duty applications.

Absolutely. Custom sizes, colors, hardness levels, tether holes, and ergonomic designs are available to meet your operational and safety requirements.