Polyurethane Wheels with Bearings

Polyurethane wheels with bearings provide superior durability, resistance to wear, and efficient movement. Whether you need wheels for carts, conveyors, or industrial machinery, polyurethane offers the ideal solution for smooth and long-lasting operation. Equipped with high-performance bearings, these wheels minimize friction, reduce maintenance costs, and optimize productivity.

Polyurethane wheels with Bearings for Logistics

Key Benefits of Polyurethane Wheels with Bearings

- Enhanced Durability

- Smooth Operation

- Load-Bearing Capacity

- Low Maintenance

Applications of Polyurethane Wheels with Bearings

- Material Handling: Carts, trolleys, or conveyors where smooth movement is critical.

- Industrial Equipment: Heavy-duty machinery that requires durable wheels to support equipment without failure.

- Precision Equipment: Robotics and automated systems that demand high accuracy and smooth, frictionless motion.

- Warehouse: Used in pallet jacks, forklifts, and storage carts.

- Medical Equipment: Hospital Carts and diagnostic machines that need to operate quietly and reliably.

Customize Polyurethane Bearings for Replacement

- Product Specifications

- Gallery

Material

- Wheel Material: High-quality polyurethane (PU) for durability, abrasion resistance, and flexibility.

- Bearing Type: Standard ball bearings or precision bearings, depending on the application.

- Durometer (Hardness): Available in a range of shore A hardness (typically from 70A to 95A), allowing you to select the ideal balance of rigidity and flexibility for your application.

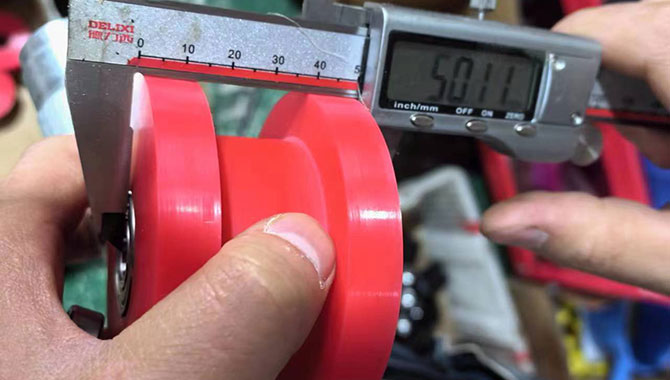

Size

- Wheel Diameter:Available in various diameters, from 2 inches (50mm) to 12 inches (300mm), with custom sizes upon request.

- Wheel Width: Typically ranges from 1 inch (25mm) to 4 inches (100mm). Custom widths are available for specific applications.

- Bearing Size:Compatible with industry-standard 608, 6200, or 6250 bearings, and can be customized based on your requirements.

Load Capacity

- Load Range:Each polyurethane wheel with bearings is designed to carry different load capacities, typically ranging from 100 lbs (45 kg) to 1,000 lbs (450 kg) per wheel, depending on the size and bearing configuration.

- Special Load Customization: High-load versions are available for heavy-duty applications. Custom load-bearing capacities can be tailored to suit specific needs.

Bearing Performance

- Sealed Bearings: For dust and moisture protection, providing longer lifespan and lower maintenance.

- Precision Bearings: For smoother, quieter, and faster movement in applications requiring high precision.

- Lubrication: Pre-lubricated for smooth rotation and reduced friction, minimizing wear over time.

Environmental Resistance

- Temperature Range:Can operate in a wide temperature range of -30°F to 180°F (-34°C to 82°C), making them suitable for both cold and hot environments.

- Chemical Resistance:Resistant to many common chemicals, oils, and greases, offering reliable performance in industrial and food processing environments.

- UV and Ozone Resistance: The polyurethane material offers resistance to UV degradation and ozone, making it suitable for outdoor and harsh environments.

Surface Compatibility

- Suitable for Smooth and Rough Surfaces: Ideal for a variety of surfaces, including concrete, wood, tiles, and metal.

- Non-Marking Option: Available in non-marking formulations to prevent damage to floors and surfaces in sensitive environments.

Customization Options

- Color: Available in standard colors such as yellow, blue, black, or custom colors upon request.

- Core Design: Can be customized with various core materials such as steel, aluminum, or nylon, depending on the strength and weight requirements.

- Special Features: Custom tread patterns, anti-slip coatings, and various hardness grades to fit specific needs.

Performance Data of Thermoplastic Polyurethane Elastomers S1190

| Material properties | Test standard | Unit | Physical value |

| Density | ASTM D792 | g/cm³ | 1.2 |

| Shore Hardness | ASTM D2240 | Shore A | 92 |

| 100% Modulus | ASTM D412 | Mpa | 8.97 |

| 300% Modulus | ASTM D412 | Mpa | 29.38 |

| UV class | A method 48H | Class | 2.5 |

| Tensile strength | ASTM D412 | Mpa | 53.93 |

| Elongation at break | ASTM D412 | % | 413.34 |

| Tear strength | ASTM D642 | N/mm | 126.33 |

| Precipitation | Temperature 75 Humidity 75 24H | Light |

Polyester polyol/TDI series prepolymer

| Model | D3136 | D3145 | D3160 |

| NCO content / % | 3.6±0.1 | 4.5±0.2 | 6.0±0.2 |

| State of matter At 20℃ | White waxy solid | White waxy solid | White waxy solid |

| MOCA 100g prepolymer dosage /g | 10.5 | 13.2 | 17.2 |

| Viscosity(85℃)/ mpa * s | 1800 | 1200 | 900 |

| Mixing Temperature /℃(prepolymer/MOCA) | 85/120 | 80/120 | 75/120 |

| Gel time /min | 9 | 7.5 | 5 |

| Post vulcanization time (100℃)/h | 10 | 10 | 10 |

| Hardness ( shore A) | 85±1 | 91±1 | 96A±1 (54D) |

| 100% constant tensile stress /MPa | 4.2 | 6.7 | 11.5 |

| 300% constant tensile stress /MPa | 8.3 | 12.5 | 21.3 |

| Tensile strength /MPa | 48 | 52 | 55 |

| Elongation at break / % | 670 | 610 | 530 |

| Tear strength (right angle) /(KN/m) | 75 | 95 | 124 |

| Tear strength (pants type) /(KN/m) | 34 | 42 | 49 |

| Rebound /% | 39 | 32 | 33 |

| Density (25℃)/(g/cm) | 1.26 | 1.27 | 1.29 |

| wearing out by friction mm³ | 40 | 48 | 57 |

Related Products

Polyurethane Wheels Manufacturers and Supplier

As a leading manufacturer of polyurethane products, we specialize in custom solutions tailored to your needs. Whether you're looking for high-performance wheels, bearings, or molded components, we provide durable, cost-effective solutions backed by years of industry expertise. Our polyurethane wheels with bearings are designed to deliver reliable, long-term performance across various applications.

Contact us now! To customize polyurethane rollers wheels for your equipment to achieve optimal efficiency.

Polyurethane wheels offer superior durability, abrasion resistance, and load-bearing capacity compared to rubber wheels. They also provide smoother movement and are less likely to degrade in harsh environments, making them ideal for heavy-duty industrial applications.

Yes, urethane bearing wheels are suitable for outdoor use, as they resist environmental factors like moisture, UV exposure, and light chemicals. However, for extreme outdoor conditions (e.g., heavy exposure to chemicals or high temperatures), we recommend discussing your specific needs for customization.

The key factors to consider include load capacity, surface type (smooth or rough), environmental conditions (indoor or outdoor), and wheel size. We recommend discussing your specific requirements with our team so we can help you select the best wheel based on your needs.

The load capacity varies depending on the wheel size, design, and the type of bearing used. Polyurethane wheels are known for handling heavy loads and can support up to several hundred kilograms per wheel, depending on your application needs.

Yes, we offer customization options for size, hardness, bearing type, and wheel design to meet the specific needs of your application. Whether you need different diameters, load-bearing capacities, or specialized features, we can tailor the wheels to your requirements.