Round Drive Belt

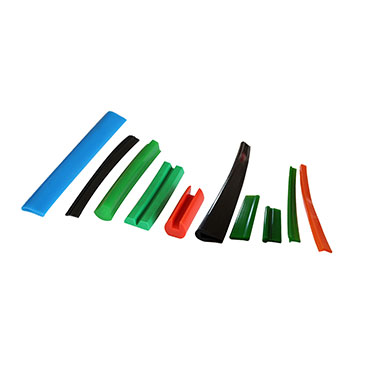

Round drive belt are round-cross section belt for power transmission systems, usually made of TPU thermoplastic polyurethane elastomers. It’s flexibility,durability, and easy to hot welding. Polyurethane Round Drive Belts are common in conveyors,motors, small machinery and automation systems.

Round Drive Belt Manufacturer and Suppliers in China

Advantages of Polyurethane Round Drive Belts

- Abrasion Resistance and Durability

- Elasticity, Flexibility and can bend easily around pulleys

- Smooth or Rough Surface as Option

- Custom Lengths and Color

Applications of Round Drive Belts

- Packaging and labeling machines

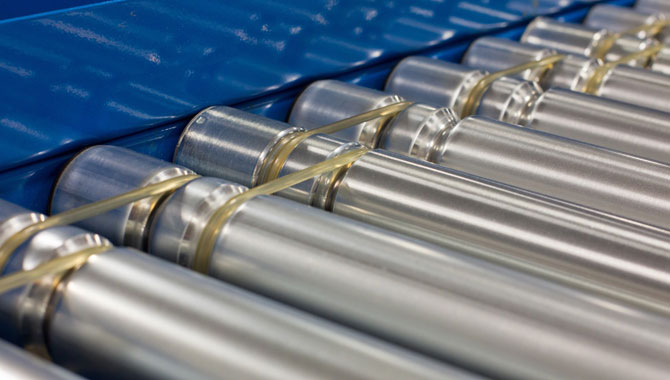

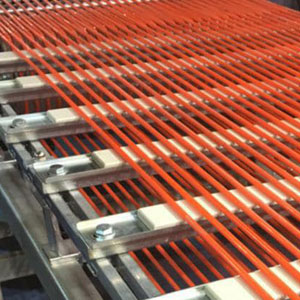

- Conveyor systems in light to medium-duty use

- Textile machines

- Office equipment (printers, copiers)

- Robotics and automation

- Food processing equipment (FDA belts)

Round Drive Belts for Power Transmission and Conveyor Belts

- Product Specifications

- Gallery

| Specification | Description |

| Cross-Section Shape | Round (circular) |

| Diameter Range | 2 mm – 20 mm (custom diameters available) |

| Material | Polyurethane (standard), Polycord,Silicone |

| Hardness (Shore A) | 85A – 90 shore A |

| Color | Green, Orange, Red, Black (others available upon request) |

| Tensile Strength | Approx. 30–50 MPa depending on the material |

| Elongation at Break | Typically 300% – 600% |

| Operating Temperature | -30°C to +80°C (intermittent up to 100°C for polyurethane) |

| Surface Type | Smooth or roughened for grip (textured belts available) |

| Resistance | Abrasion, oil, ozone, and chemical resistance (varies by material) |

| Joint Type | Welded (thermoplastic), endless loop, or mechanical fastening |

| Length | Standard coils (30m, 50m, 100m) or cut-to-length; joined or endless belts |

Optional Features (Customizable) for PU Round Drive Belts

- Reinforced Core: With Kevlar or steel cords for high-tension applications

- FDA-Compliant Material: For food and beverage processing industries

- Anti-Static Properties: For electronics or cleanroom applications

- Color Coding: For easy belt identification in different systems

- Joining Kits: Heat welding tools for on-site belt joining.

Related Products

Polyurethane Round Drive Belt Suppliers in China– Custom Polyurethane Solutions

As trusted Round Drive Belt suppliers in Liyang, Changzhou City, we specialize in providing high-quality polyurethane round drive belts tailored to meet the specific needs of industrial, mechanical, and automation applications. Whether you're looking for durable belts for conveyors, compact systems, or custom-sized belts for specialized equipment, we offer precision-engineered solutions with consistent performance and long service life.

Our strength lies in custom polyurethane molding, allowing us to manufacture belts in a wide range of diameters, hardness levels, and lengths—perfect for non-standard or high-demand operating environments. Each belt is produced using high-performance polyurethane materials that ensure exceptional flexibility, abrasion resistance, and reliability under continuous load.

As a local manufacturer and supplier, we offer:

- Fast response and lead times

- One-on-one technical support and design customization

- Competitive pricing for both domestic and international orders

- Bulk and small batch production flexibility

If you're looking for a reliable round drive belt supplier in Changzhou with advanced manufacturing capabilities and full customization services, we’re your ideal partner. Let us help you optimize your machinery with belts that are built to perform and built to last.

Yes. As a polyurethane manufacturer, we specialize in custom molding solutions. We can produce belts to your required diameter, length, hardness, and color, including reinforced or FDA-compliant versions for food-grade use.

Consider factors like load, speed, pulley diameter, temperature range, and working environment. We can assist you in selecting the right polyurethane material and belt specifications based on your machine’s working conditions.

Yes. Our polyurethane belts can be heat welded using joining kits. We also supply pre-welded endless belts for convenience or provide guidance on proper joining techniques if done on-site.

They’re suitable for both. Round belts are commonly used in light-load conveying applications, especially in packaging, food processing, and sorting systems. Their flexibility and grip make them ideal for curved or small-radius conveyor systems.

Lead times depend on the complexity and quantity of the order, but standard polyurethane round belts ship within 5–7 working days.