Urethane Applications in Subsea Cable Protection Systems

Subsea Cable Protection Systems are critical for power transmission, telecommunications, and offshore energy applications. Polyurethane components in these systems provide high tensile strength, abrasion resistance, and chemical durability, protecting cables from mechanical stress, seawater corrosion, and environmental damage.

Urethane’s flexibility allows cables in Subsea Cable Protection Systems to bend with ocean currents without cracking, while its wear resistance preserves cable integrity over long-term deployments.

Why Choose Polyurethane in Submarine Cable Protection

Polyurethane withstands extreme pressure, continuous saltwater exposure, and mechanical stress, ensuring long service life. Its flexibility and moldability allow for custom solutions tailored to offshore installation needs, supporting reliable power transmission, telecommunications, and energy projects.

Key Urethane Components

- Cable Jackets – Urethane jackets shield cables from physical damage, moisture, and chemical exposure. Their flexibility allows for bending without compromising protection.

- Seals and Gaskets – Urethane seals prevent water ingress at joints and terminations, ensuring internal components remain dry and fully protected.

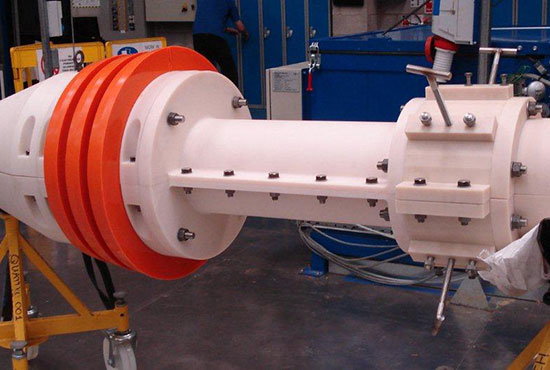

- Bend Restrictors – High-strength urethane restrictors prevent excessive bending of flexible pipes and cables, avoiding fatigue and mechanical failures.

- Riser Clamps – Lightweight, impact-resistant urethane clamps replace steel, securing subsea cables and preventing bending during operation.

- J-Tube Seals – Designed for subsea J-tubes, urethane seals block water, debris, and contaminants while guiding cables safely through protective conduits.

Industries & Scenarios in Subsea Cable Protection Systems

- Offshore Power Transmission – Polyurethane bend restrictors, riser clamps, and protective jackets ensure the safe deployment of subsea power cables, reducing wear and preventing mechanical failures.

- Telecommunications – Urethane components protect subsea communication cables from abrasion, bending, and water ingress, ensuring reliable data transmission over long distances.

- Offshore Oil & Gas – Subsea pipelines and umbilicals benefit from polyurethane seals and protective sleeves that prevent leaks, resist chemical exposure, and extend equipment life.

- Renewable Energy – In offshore wind and tidal energy projects, urethane cable protection pipes and J-tube seals safeguard flexible power lines, reducing maintenance costs and improving operational reliability.

- Subsea Infrastructure Projects – Urethane products support cable routing, reinforcement, and vibration absorption in underwater construction projects, enhancing durability and system efficiency.

Benefits of Using Urethane

- Enhanced Cable Protection – Urethane components reduce wear, prevent damage, and extend cable lifespan.

- Long-Term Cost Savings – Durable materials lower maintenance and replacement costs in offshore environments.

- Design Flexibility – Components can be molded to meet custom geometries for various subsea installations.

- Environmental Compatibility – Polyurethane products minimize environmental impact compared to some traditional materials.

Learn More About Polyurethane in Other Industries

Send Inquiry